Preparation method of aroma enhancement particle for cigarette filter tip and cigarette filter tip

A filter tip and particle technology, applied in e-liquid filter, application, tobacco and other directions, can solve the problems of inconspicuous characteristics and insufficient aroma of cigarette smoke, and achieve the effect of improving comfort and reducing harm

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

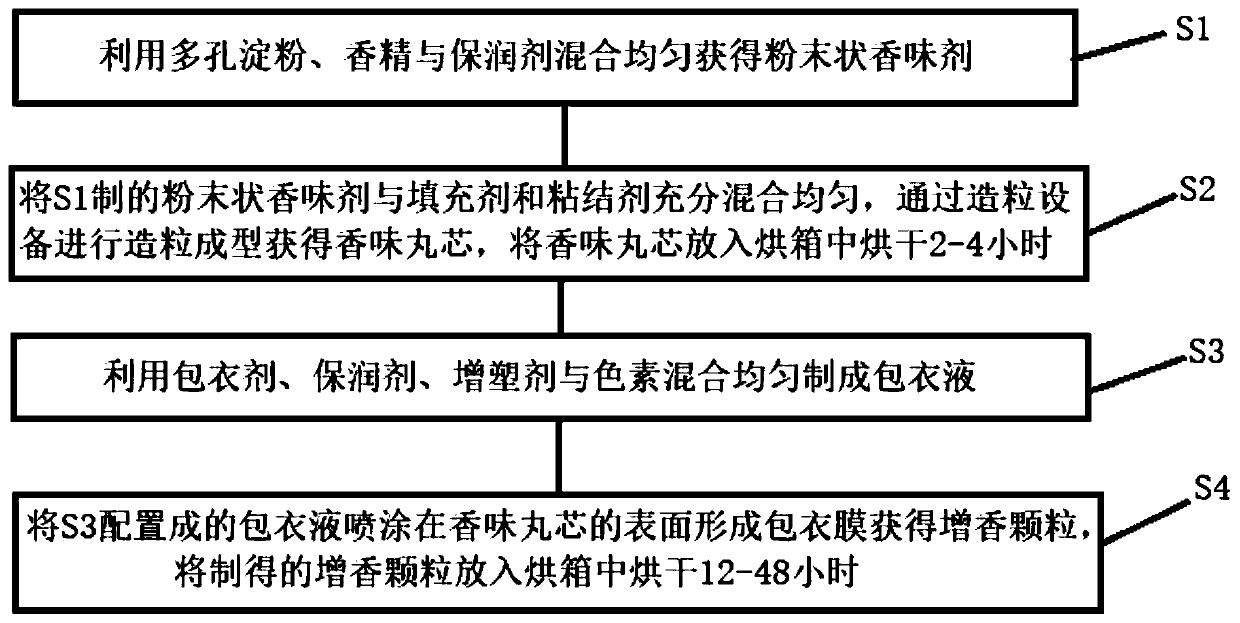

[0023] Such as figure 1 As shown, the method for preparing flavor-enhancing granules for cigarette filters according to the embodiment of the present invention includes the following steps: S1, using porous starch, essence and humectant to mix uniformly to obtain a powdered flavoring agent; S2, making the powdered flavoring agent prepared by S1 The fragrance agent is fully mixed with the filler and the binder, and the fragrance pellet core is obtained by granulating and forming by granulation equipment, and the fragrance pellet core is put into an oven to dry for 2-4 hours; S3, using a coating agent, moisturizing Agent, plasticizer and pigment are mixed evenly to make a coating liquid; S4, the coating liquid C configured in S3 is sprayed on the surface of the scented ball core to form a coating film to obtain flavoring granules, and the prepared flavoring granules are put Dry in the oven for 12-48 hours.

[0024] The cigarette filter according to the embodiment of the present...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com