Processing method of sunflower seed oil and application of waste thereof

A processing method, sunflower oil technology, applied in the field of physics and chemistry, can solve the problems of sterol and vitamin loss in oil, natural VE loss of sunflower oil, and inability to remove metal ions, etc., so as to achieve high oil quality and simple and feasible refining process , the effect of light color back

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The processing method of sunflower seed oil, it comprises the steps:

[0028] Sunflower seed kernels are crushed to remove the coat, steamed and fried, and squeezed to obtain sunflower seed crude oil;

[0029] Using an ultra-microfiltration membrane with a molecular weight cut-off of 70kD to remove lipoxygenase from sunflower seed crude oil to obtain oil product A;

[0030] Heat oil product A to 60°C, add 0.5wt% adsorption refining agent to oil product A, maintain the temperature at 60°C, stir at 200rpm for 30min, and obtain oil product B;

[0031] Add 0.05wt% citric acid to oil product B, stir at 200rpm for 30min, chelate metal ions, and obtain oil product C;

[0032] Heat the oil product C to 80°C, then add 0.1wt% of 10% (mass fraction) dilute phosphoric acid to the oil product C, maintain the temperature at 80°C, stir at 200 rpm for 60 minutes, and obtain oil product D;

[0033] Naturally cool the oil product D to 30°C, centrifuge once through a centrifuge, and col...

Embodiment 2

[0039] The processing method of sunflower seed oil, it comprises the steps:

[0040] Sunflower seed kernels are crushed to remove the coat, steamed and fried, and squeezed to obtain sunflower seed crude oil;

[0041] Using an ultra-microfiltration membrane with a molecular weight cut-off of 90kD to remove lipoxygenase from sunflower seed crude oil to obtain oil product A;

[0042] Heat oil product A to 60°C, add 0.7wt% adsorption refining agent to oil product A, maintain the temperature at 60°C, stir at 200rpm for 30min, and obtain oil product B;

[0043] Add 0.08wt% citric acid to oil product B, stir at 200rpm for 30min, chelate metal ions, and obtain oil product C;

[0044] Heat oil C to 80°C, then add 0.2wt% of 10% (mass fraction) dilute phosphoric acid to oil C, maintain the temperature at 80°C, stir at 200 rpm for 60 minutes, and obtain oil D;

[0045] Naturally cool the oil product D to 30°C, centrifuge once through a centrifuge, and collect the heavy phase separation ...

Embodiment 3

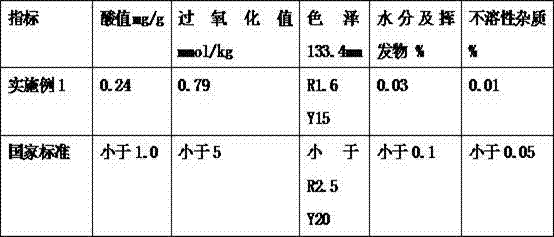

[0051] The sunflower seed oil physicochemical index of the present invention is measured:

[0052] Testing standard:

[0053] Acid value: refer to GB / T 5530-2005; peroxide value: refer to GB / T 5538-2005; color: refer to GB / T22460-2008; moisture and volatile matter: refer to GB / T 5528-2008; insoluble Impurities: Refer to GB / T 15688.

[0054] Taking Example 1 as an example, the specific test results are shown in Table 1:

[0055] Table 1

[0056]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com