High tar reduction diacetate fiber non-woven fabric filter material for cigarettes and preparation method for filter material

A technology of diacetate fiber and high coke reduction, which is applied in non-woven fabrics, textiles and papermaking, etc. It can solve the problems of complex preparation process, unsatisfactory coke reduction effect, poor cigarette taste, etc., and achieve simple process and coke reduction The effect of remarkable effect and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

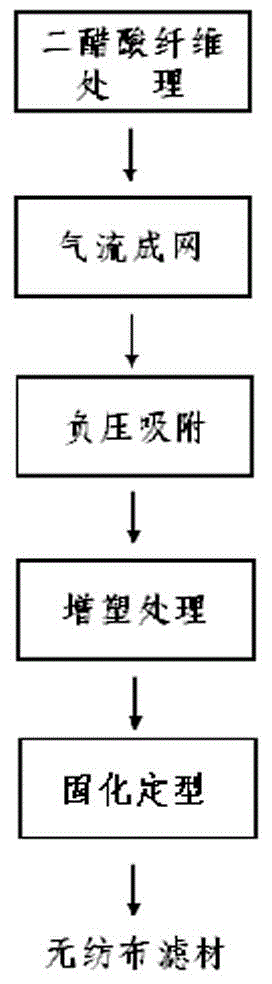

[0021] The preparation method of the present invention includes the steps of diacetate fiber treatment, air-laid, negative pressure adsorption, plasticizing treatment and curing and shaping, specifically including:

[0022] For the treatment of diacetate fibers, the diacetate fibers are firstly opened, then crushed to a size of 3-5 mm, and then set aside;

[0023] In the air-forming process, the uniformly pulverized diacetate fibers are transported to the forming net box by air flow for net-forming treatment;

[0024] The negative pressure adsorption is to adsorb the diacetate fiber to the forming net by means of negative pressure suction and control its thickness at 0.15-0.30mm;

[0025] In the plasticizing treatment, spray 5 to 15 parts by mass of a plasticizer for cigarettes with a purity of more than 99% on the front of the diacetate fiber layer; turn the diacetate layer over the net by means of negative pressure suction, and spray 5 parts by weight on the reverse side. ~...

Embodiment 1

[0031] After the evenly opened diacetate fiber tow is crushed and screened to a length of 3-5 mm, it is added in 100 parts by mass, and then transported to the forming net cage by air flow at a speed of 0.5 kg / min, and sucked under the condition of negative wind pressure of 5000 Pa. The wind falls on the mesh curtain running at 10m / min, and the nozzles arranged by the spray rods spray triacetin with a purity of more than 99% and accounting for 5% of the dry weight of the fiber to the front of the fiber layer. Under the negative wind pressure of 5000Pa, the suction The wind turns the fiber layer over the net, and sprays glycerol triacetate with a purity of more than 99% and 5% of the dry weight of the fiber on the opposite side, solidifies and shapes, and the non-woven fabric filter material for cigarette filter rods produced has a weight of 40g / m 2 , thickness 0.30mm, rolled into a filter rod, compared with the control (acetate white rod), the tar reduction rate reached 30%, an...

Embodiment 2

[0033] After the evenly opened diacetate fiber tow is crushed and screened to a length of 3-5 mm, it is added in 100 parts by mass, and then transported to the forming cage by air flow at a speed of 1.0 kg / min, and sucked under the condition of 6000 Pa negative wind pressure. The wind falls on the mesh curtain running at 25m / min, and the nozzles arranged by the spray rods spray triethylene glycol diacetate with a purity of more than 99% and accounting for 10% of the dry weight of the fiber to the front of the fiber layer. Under the condition of 6000Pa negative wind pressure Next, suck the air to turn the fiber layer over the net, spray triethylene glycol diacetate with a purity of more than 99% and account for 10% of the dry weight of the fiber on the reverse side, solidify and shape, and the non-woven fabric filter material for cigarette filter rods made Weight 45g / m 2 , with a thickness of 0.2mm, rolled into a filter rod, and compared with the control (acetate white rod), th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com