Method for preparing fatty acid stephanoporate starch ester and application thereof

A technology of porous starch and fatty acid, applied in the field of modified starch, to achieve the effects of easy implementation, increased hydrophobicity, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

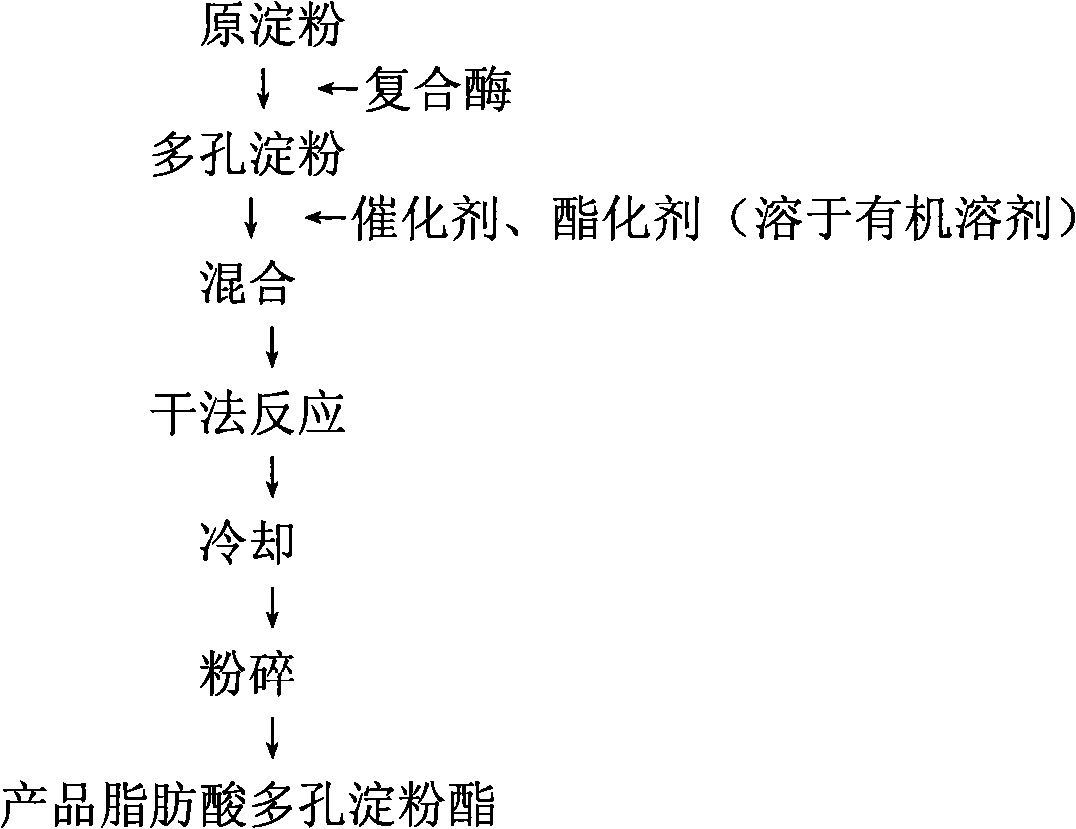

Method used

Image

Examples

Embodiment 1

[0024] Example 1: Weigh 100g (dry basis) cornstarch, place it in 170mL of disodium hydrogen phosphate-citric acid buffer solution with a pH value of 4.6, and measure 15mL compound enzyme solution at the same time, and use 30mL buffer solution to make enzyme solution , poured into the starch suspension and stirred for 24 hours, adding sodium hydroxide to stop the reaction, centrifuging to remove the supernatant, washing, drying, and crushing to obtain a porous starch sample.

[0025] Weigh 3g of stearic acid, dissolve it in 60mL of 60°C dehydrated ethanol, slowly add it to 100g of porous starch (dry basis), add 0.06g of hydrochloric acid, stir well, and obtain a uniform mixture slurry, sieve, and dry Ethanol, water was added to adjust the water mass fraction to 20%, the resulting mixed reactant was placed in a pressure cooker, and esterification was carried out at 130° C. for 3 hours, cooled and pulverized to obtain corn porous starch stearate.

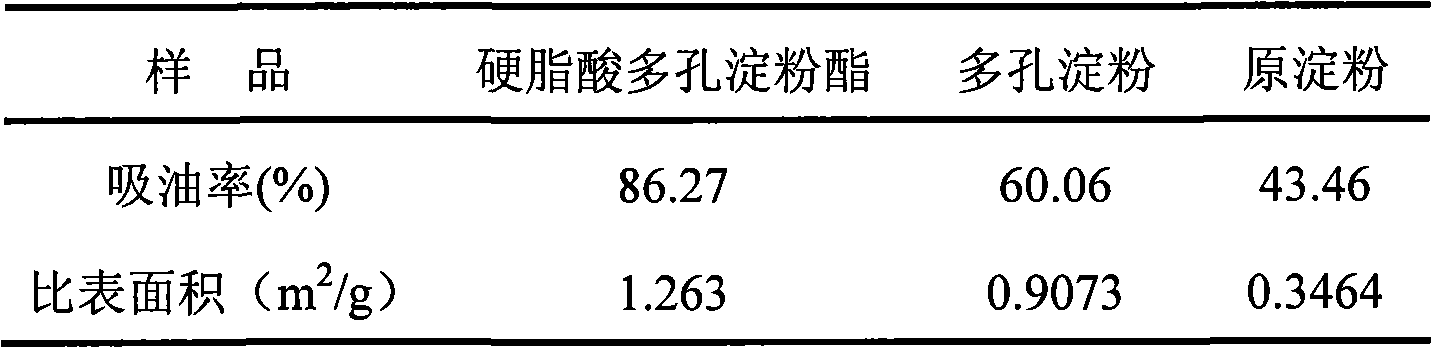

[0026] Compare the properties o...

Embodiment 2

[0030] Example 2: Weigh 100g (dry basis) cornstarch, place in 160mL pH value of 4.6 disodium hydrogen phosphate-citric acid buffer, and measure 18mL compound enzyme solution at the same time, use 40mL buffer to make enzyme solution , poured into the starch suspension and stirred for 24 hours, adding sodium hydroxide to stop the reaction, centrifuging to remove the supernatant, washing, drying, and crushing to obtain a porous starch sample.

[0031] Weigh 3g of stearic acid, dissolve it in 60mL of 60°C absolute ethanol, slowly add it to 100g of porous starch (dry basis), add 0.1g of acetic acid, stir well, and obtain a uniform mixture slurry, sieve, and dry Ethanol, water was added to adjust the water mass fraction to 20%, the resulting mixed reactant was placed in a pressure cooker, and esterification was carried out at 130° C. for 3 hours, cooled and pulverized to obtain corn porous starch stearate.

Embodiment 3

[0033] Cornstarch was used as raw material, stearic acid was used as esterification agent, and the esterification reaction temperature was 150° C., and the rest of the formula and operating conditions were the same as those in Example 1 or Example 2 to obtain the finished porous cornstarch stearate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com