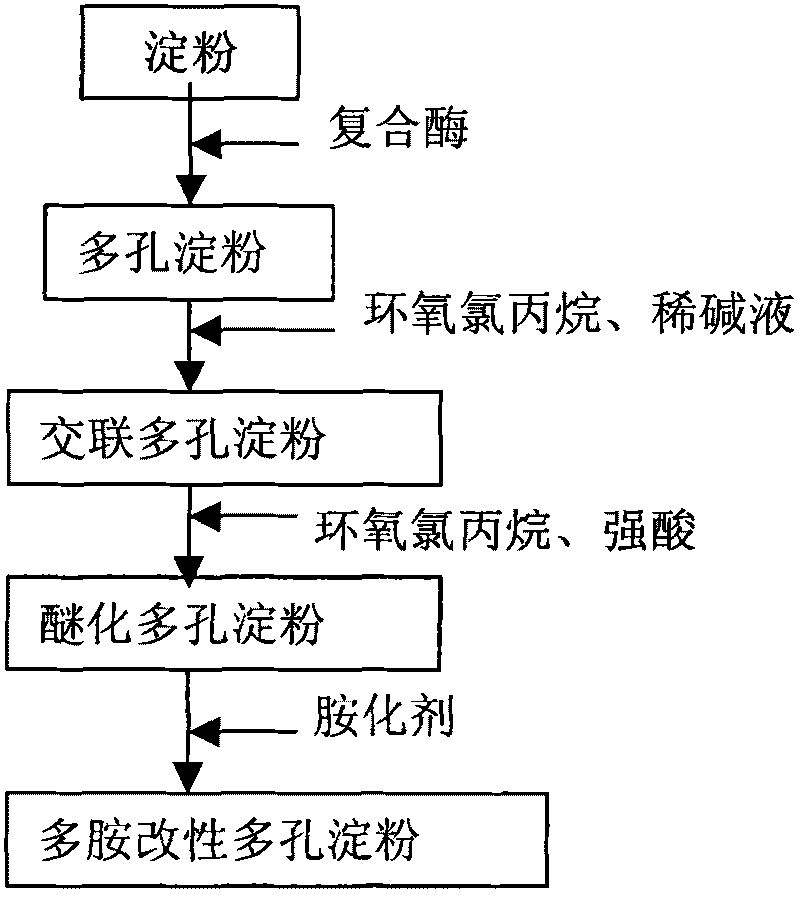

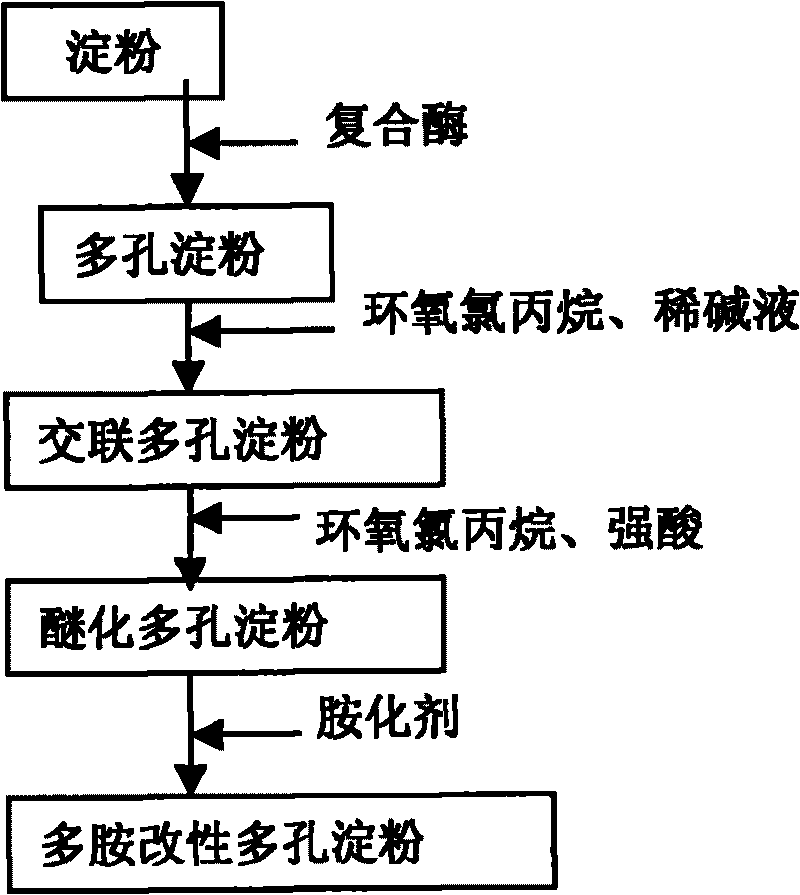

Method for preparing modified polyamine porous starch

A technology of porous starch and amine modification, applied in the field of modified starch, achieves the effect of high removal rate of sulfonic acid group, saving social resources and high utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] First, 30 g of commercially available potato starch was used as a raw material and dissolved in 200 mL of a buffer solution with a pH of 5 to obtain a starch slurry with a starch concentration of 15% by mass. The buffer solution is obtained by measuring the mass ratio of citric acid: disodium hydrogen phosphate = 1:2, and then adding water and stirring evenly. Then add the compound enzyme that is made up of the glucoamylase of 0.15g and 0.75g α-amylase in the starch slurry, the addition of compound enzyme is 3.0% of starch weight, then at 45 ℃ and constant temperature reaction 8h under the condition of shaking in water bath, then Take it out from the water bath and add 5 mL of 4% sodium hydroxide solution by mass percentage to terminate the enzymatic hydrolysis reaction. Then filter and separate to obtain the solid and supernatant, wash the solid with distilled water until the pH value is neutral, and finally vacuum-dry at 45°C for 12 hours to obtain a white powder that...

Embodiment 2

[0035]30g potato starch was dissolved in the same 200mL pH as in Example 1 in the buffer solution of sodium citrate-disodium hydrogen phosphate of 5 to obtain a starch slurry with a concentration of 15% by mass. Add a compound enzyme consisting of 0.25 g of glucoamylase and 0.50 g of α-amylase to the starch slurry. The amount of the compound enzyme added is 2.5% of the weight of the starch, followed by a constant temperature reaction at 60 ° C and a water bath for 18 hours, then taken out and removed. Add 5 mL of 4% sodium hydroxide solution by mass to terminate the enzymatic hydrolysis reaction. Then filter and separate to obtain the solid and supernatant, wash the solid with distilled water until the pH value is neutral, and finally vacuum-dry at 45°C for 12 hours to obtain a white powder that is porous starch, and the porous starch has a water absorption rate of ≥1.73g / g

[0036] Add 20mL of dilute lye and 2mL of epichlorohydrin to 5g of porous starch, stir and mix well, th...

Embodiment 3

[0040] Corn starch is used as raw material, diethylenetriamine is used as polyamine agent, and other formulas and processes are the same as those in Example 1 to obtain diethylenetriamine-modified corn porous starch.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com