Water-soluble fragrance microcapsule having slow release characteristics and preparation method thereof

A water-soluble, microcapsule technology, applied in the preparation of water-soluble aromatic microcapsules, water-soluble aromatic microcapsules and the field of preparation thereof, can solve the problems of application limitation, low coating rate, influence on the smell of microcapsule products, etc. Storage performance, simple preparation process, small loss of aromatic substances

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

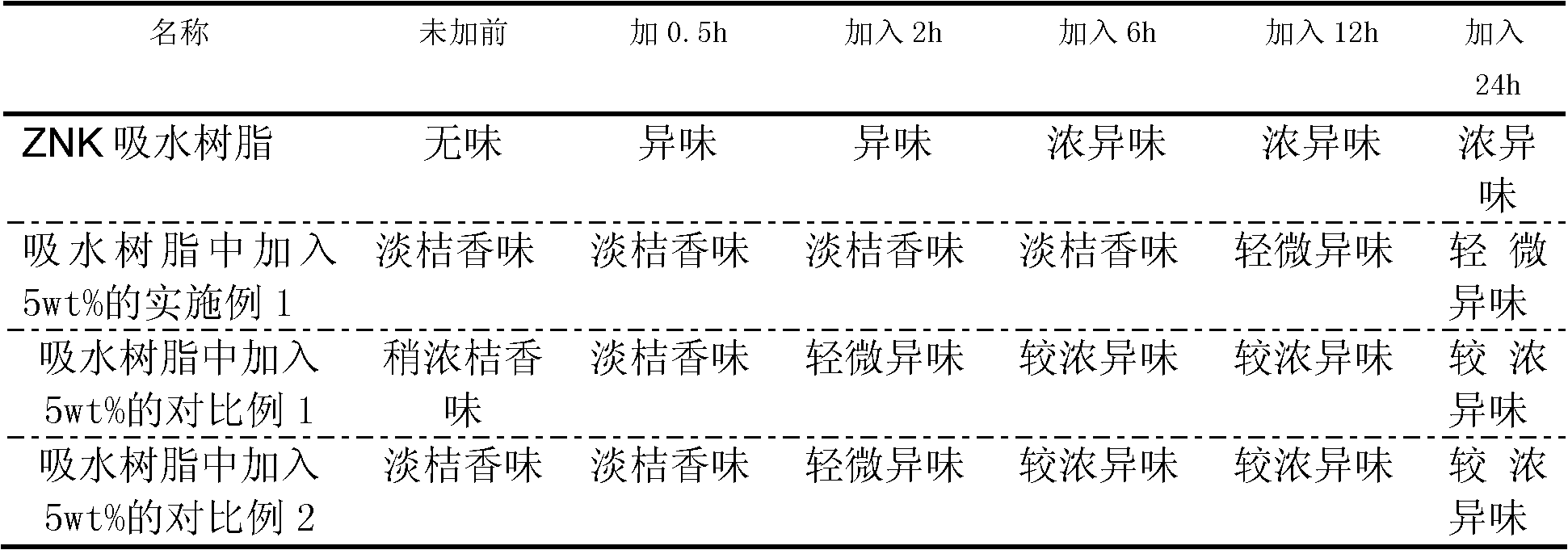

Examples

Embodiment 1

[0018] (1) Add 500g of porous starch to the mixing machine, and the oil absorption value of the starch is >1.5g / g. Add 100g of oil-soluble lemon essence in batches while stirring, so that the essence is evenly absorbed into the porous starch;

[0019] (2) Add 1000g of polyethylene glycol 6000 into a stirred tank with a heating device, heat to 80°C to completely melt the polyethylene glycol, and add the polyethylene glycol prepared in step (1) under stirring conditions. The prepared porous starch that has absorbed essential oils was stirred quickly to disperse the porous starch evenly in polyethylene glycol, and then the mixture was quickly poured into an open pan and cooled naturally below 25°C. The polyethylene glycol to be coated with porous starch After the alcohol is completely cooled and solidified, it is pulverized to an average particle size of 220 μm to obtain water-soluble aromatic microcapsules with sustained release characteristics.

Embodiment 2

[0021] In embodiment 1, the lemon essence in step 1 is changed into rose essence, and all the other are with embodiment 1. The particle size of the product is 200-300 μm.

Embodiment 3

[0023] In Example 1, the polyethylene glycol 6000 in step 2 was replaced with Polyethylene Glycol 2000, and the rest were the same as in Example 1. The average particle size of the product is 300 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com