A kind of preparation method of porous starch with emulsification

A technology of porous starch and emulsification, applied in chemical instruments and methods, inorganic chemistry, alkali metal compounds, etc., can solve the problems of inability to emulsify and achieve the effects of less pollution, simple operation and simplified production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

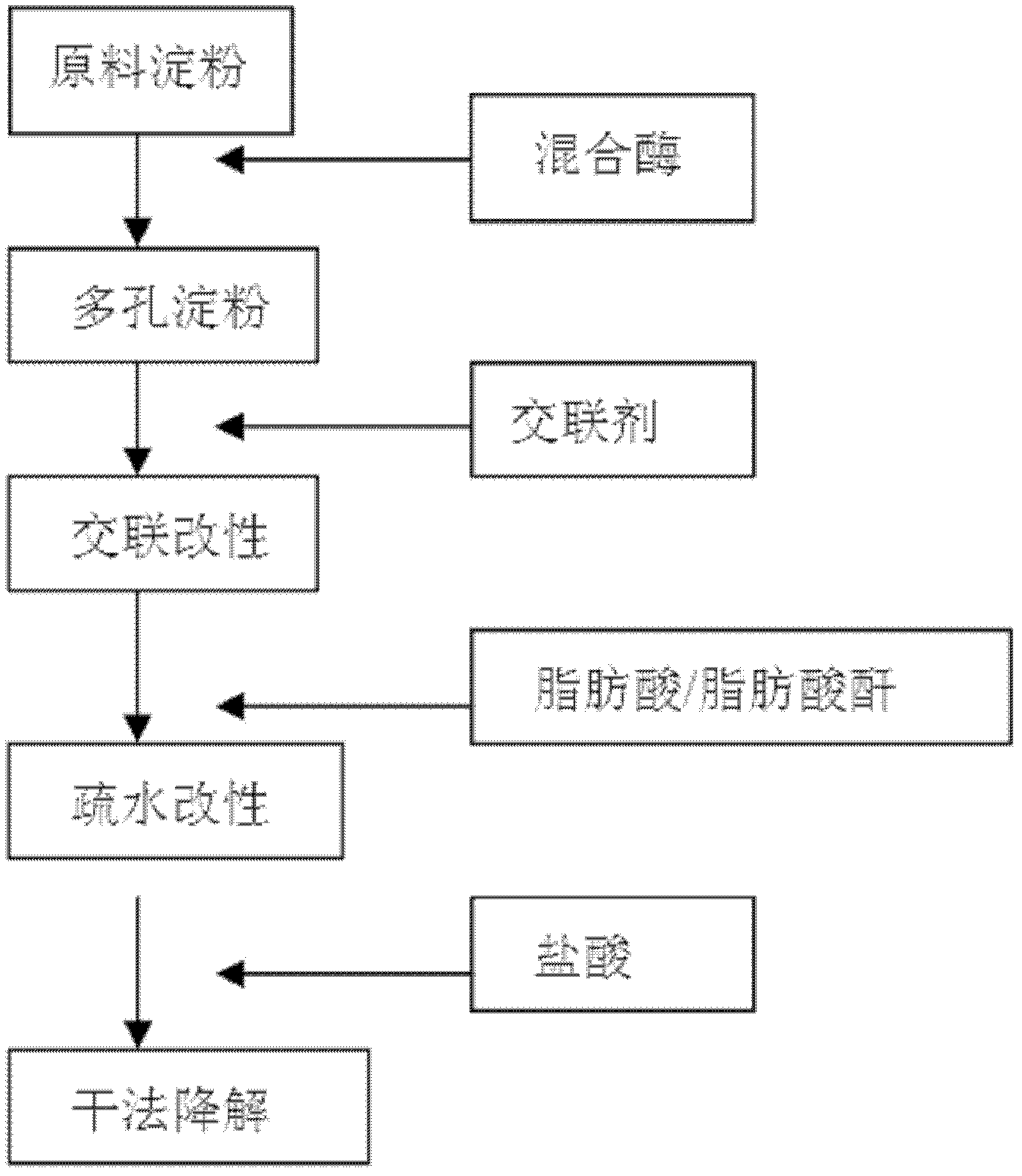

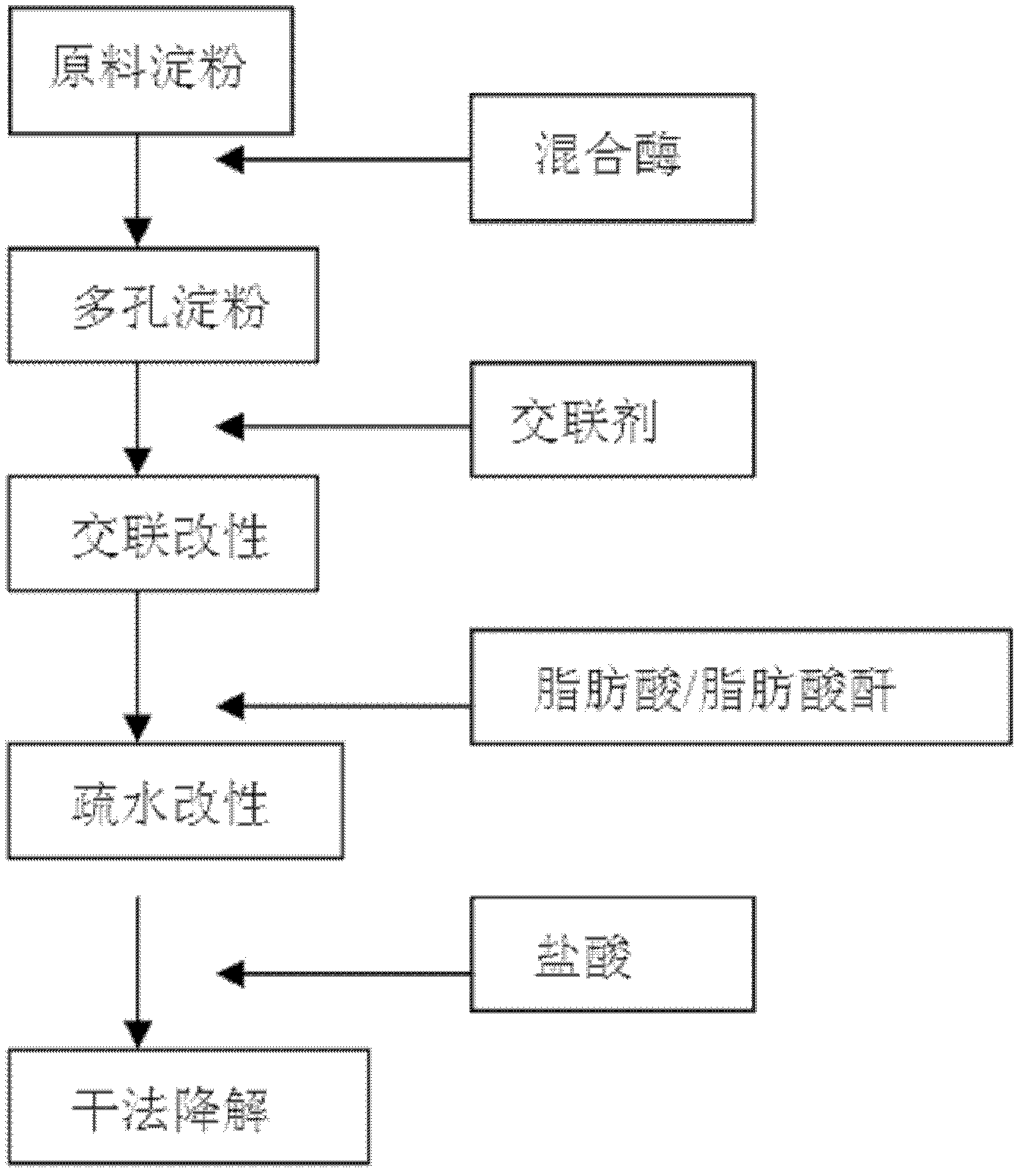

Method used

Image

Examples

Embodiment 1

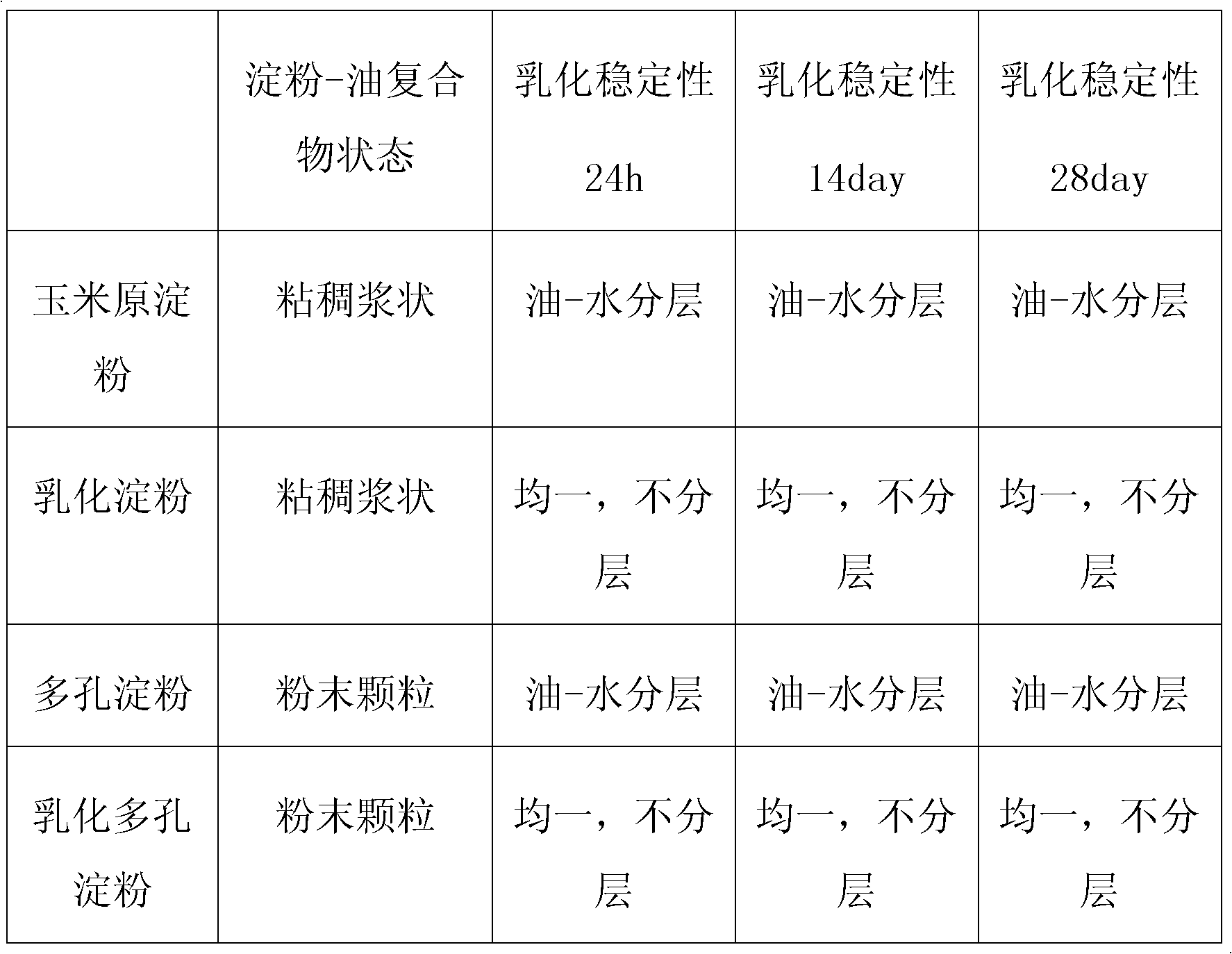

[0035] As shown in the accompanying drawing, take 100g of cornstarch (dry basis), add 150ml of acetic acid-sodium acetate buffer solution with pH=3.5, and add 5ml of mixed enzyme solution (α-amylase: glucose starch Enzyme, volume ratio = 1:5), after reacting for 20 hours, neutralize with sodium hydroxide, filter with suction and wash with distilled water, place the obtained starch in an oven at 40-50°C, and pulverize to obtain a porous starch sample.

[0036] Weigh 100g of porous starch (dry basis), mix it with 150g of water, add sodium hydroxide to adjust the solution to PH=9, the temperature is 35°C, add 0.1g of sodium trimetaphosphate under constant stirring, react for 3 hours, and then oxidize with hydrogen Sodium neutralization, suction filtration and washing with distilled water, the resulting starch is dried in an oven at 40-50°C and pulverized.

[0037] Weigh 100g (dry basis) of the above-mentioned crosslinked starch sample, mix it with 150g water, add sodium hydroxide...

Embodiment 2

[0045] Weigh 100g of cornstarch (dry basis), add 100ml of acetic acid-sodium acetate buffer solution with pH=6, and add 5ml of mixed enzyme solution (α-amylase:glucoamylase, volume ratio=1 : 2), after reacting for 40h, neutralize with sodium hydroxide, suction filter and wash with distilled water, place the obtained starch in a 40-50°C oven for drying, pulverize, and obtain a porous starch sample.

[0046] Weigh 100g of porous starch (dry basis), mix it with 200g of water, add sodium hydroxide to adjust the solution to PH=11, the temperature is 30°C, add 0.6g of sodium trimetaphosphate under constant stirring, react for 4 hours, and then oxidize with hydroxide Sodium neutralization, suction filtration and washing with distilled water, the resulting starch is dried in an oven at 40-50°C and pulverized.

[0047] Weigh 100g (dry basis) of the above crosslinked starch sample, mix it with 200g water, add sodium hydroxide to adjust the pH of the solution to 6.0, and add 0.5g of octe...

Embodiment 3

[0051] Weigh 100g of cornstarch (dry basis), add 300ml of acetic acid-sodium acetate buffer solution with pH=3, and add 5ml of mixed enzyme solution (α-amylase:glucoamylase, volume ratio=1 : 4), after reacting for 30 h, neutralize with sodium hydroxide, suction filter and wash with distilled water, place the obtained starch in a 40-50°C oven for drying, pulverize, and obtain a porous starch sample.

[0052] Weigh 100g of porous starch (dry basis), mix it with 100g of water, add sodium hydroxide to adjust the solution to PH=10, and the temperature is 25°C. Under constant stirring, add 1g of sodium trimetaphosphate, react for 5 hours, and use sodium hydroxide to Neutralize, filter with suction and wash with distilled water, place the obtained starch in a 40-50°C oven to dry, and pulverize.

[0053] Weigh 100g (dry basis) of the above-mentioned crosslinked starch sample, mix it with 100g water, add sodium hydroxide to adjust the pH of the solution to 8.0, and add 2g of octenyl su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com