Modified starch particle, preparation and application thereof

A starch granule and modification technology, applied in application, food science, tobacco and other directions, can solve the problems of large negative impact on the smoking quality of flue-cured cigarettes, unsatisfactory adsorption of harmful gas phase components, and no solution. Achieve the effect of reducing tar and carbon monoxide delivery, improving sensory quality, and improving sensory comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

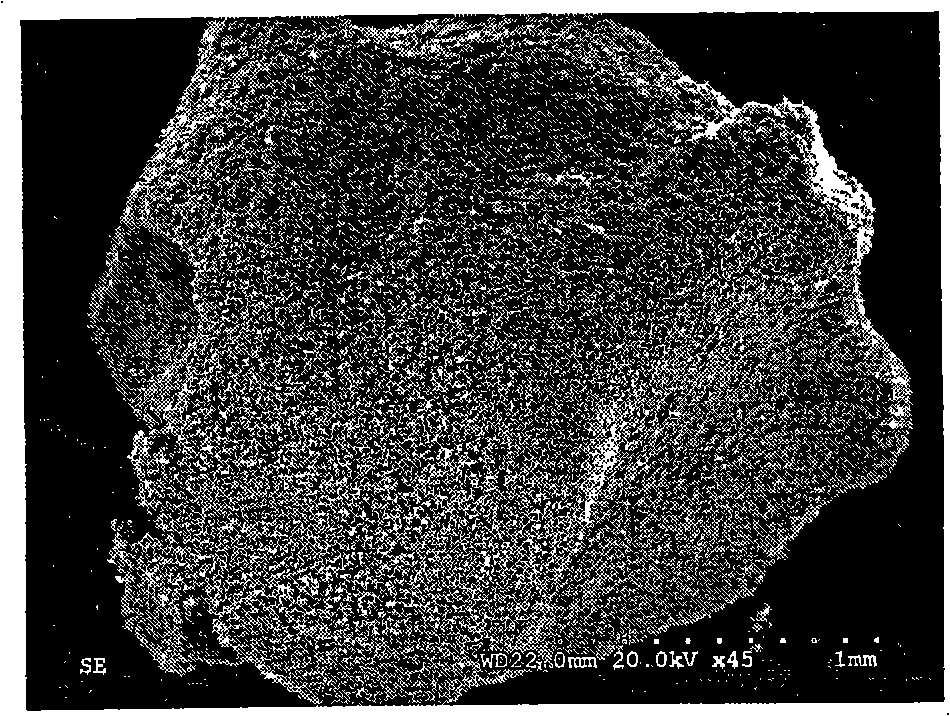

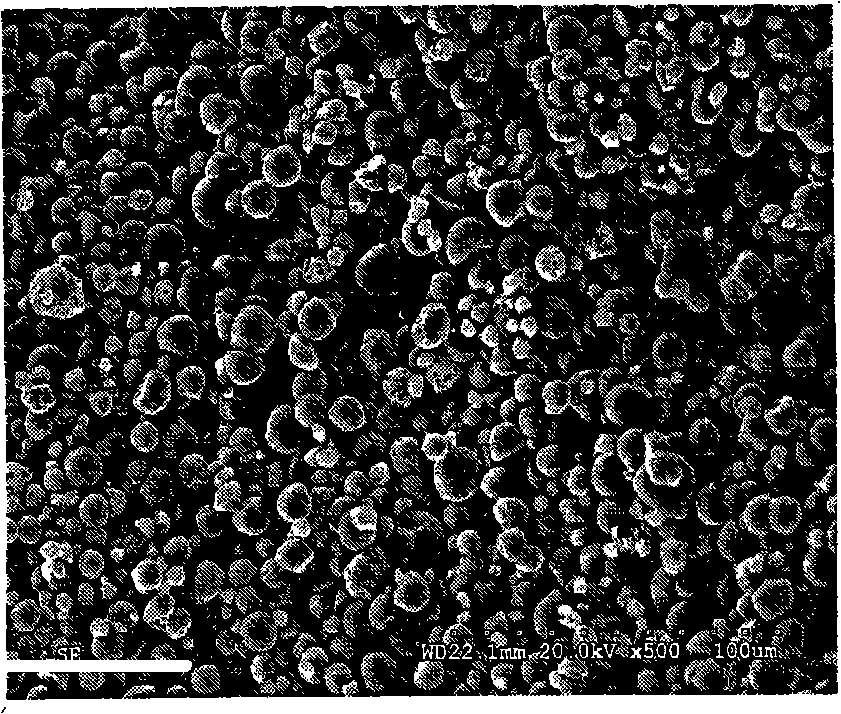

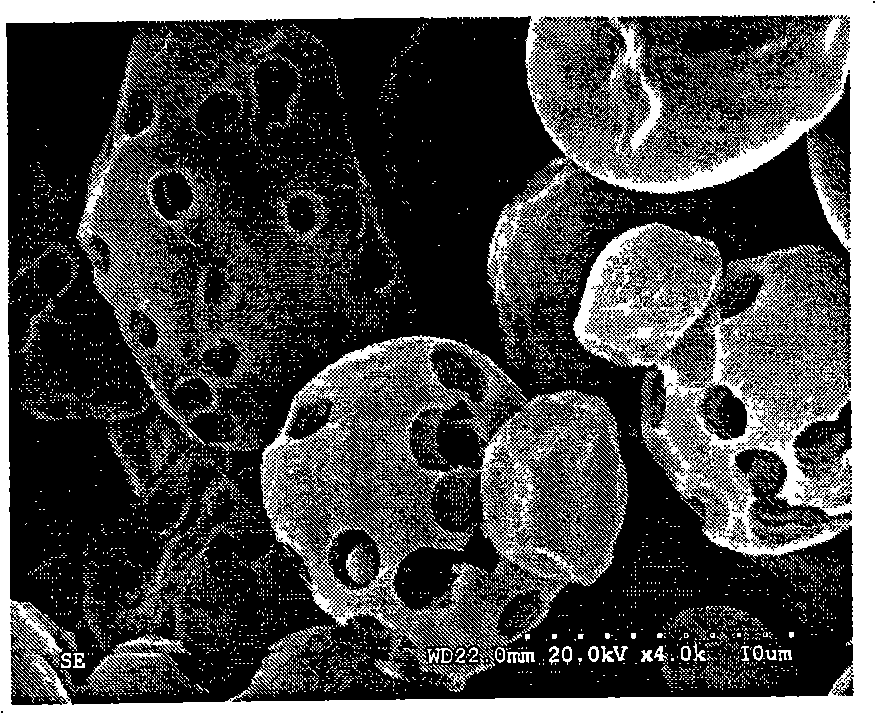

[0040] Take 20g starch, add 40mL, 0.1mol / L, acetic acid buffer solution with a pH value of 3.5, stir evenly at 50°C, prepare starch milk, add 0.2g glucoamylase, and stir at 50°C for enzymolysis for 20 After 1 hour, add 1 ml of sodium hydroxide with a concentration of 4% to terminate the reaction, centrifuge to obtain a slurry-like porous starch, add 1 g of alum to the slurry-like porous starch, and then process it in a 900-watt microwave oven for 1 minute to pulverize the solidified porous starch. After a 60-mesh sieve, the desired modified starch granules are obtained. The particles were determined to be superior to activated carbon in terms of adsorption properties. The measurement results are shown in Table 1.

[0041] Table 1 Determination data of physical indicators of modified starch granules

[0042] name

Embodiment 2

[0044] Take 20g of starch, add 50mL, 0.3mol / L, acetic acid buffer solution with pH value of 4.0, stir evenly at 40°C, prepare starch milk, add 0.4g of glucoamylase, and stir at 40°C for enzymolysis After 20 hours, add 1.5mL of 3% sodium hydroxide to terminate the reaction, centrifuge to obtain a slurry-like porous starch, add 1g of alum to the slurry-like porous starch, and then treat it in a 900-watt microwave oven for 1 minute to pulverize the solidified porous starch , after passing through a 60-mesh sieve, the desired modified starch granules are obtained.

Embodiment 3

[0046] Take 20g of starch, add 60mL of 0.5mol / L acetic acid buffer solution with a pH value of 5.0, stir evenly at 55°C, and prepare starch milk with a certain concentration, add 0.5g of glucoamylase, and stir at a constant temperature at 55°C After 24 hours of enzymatic hydrolysis, add 1.0ml of 5% sodium hydroxide to terminate the reaction, centrifuge to obtain slurry-like porous starch, add 1g of alum to the slurry-like porous starch, and then treat it in a 900-watt microwave oven for 1 minute, pulverize and solidify the starch. The porous starch is passed through a 60-mesh sieve to obtain the desired modified starch granules.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com