Friction component used for wet-type friction clutch

A friction clutch and friction locking technology, applied in the field of friction components, can solve problems such as failure to be fully and effectively implemented

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

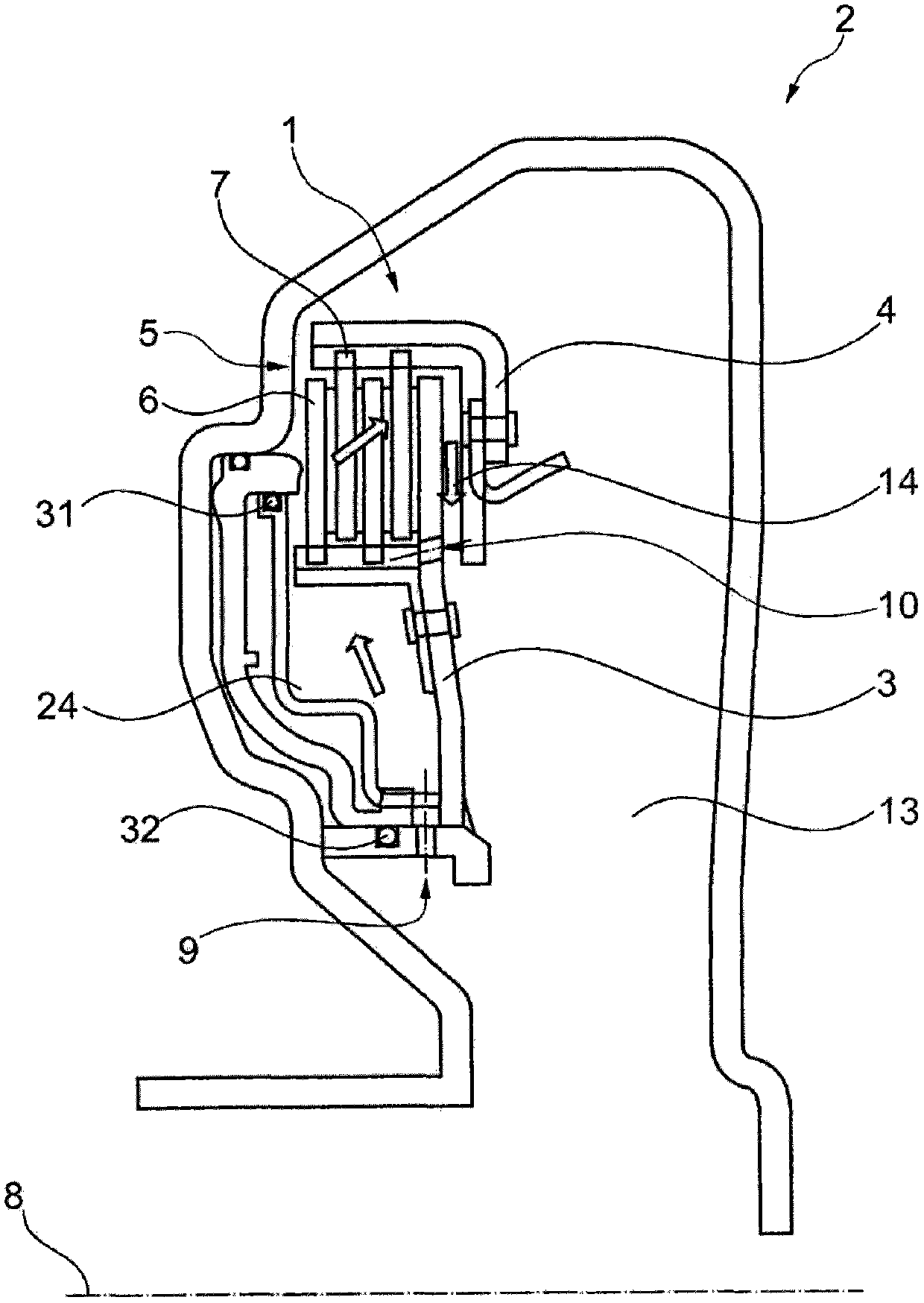

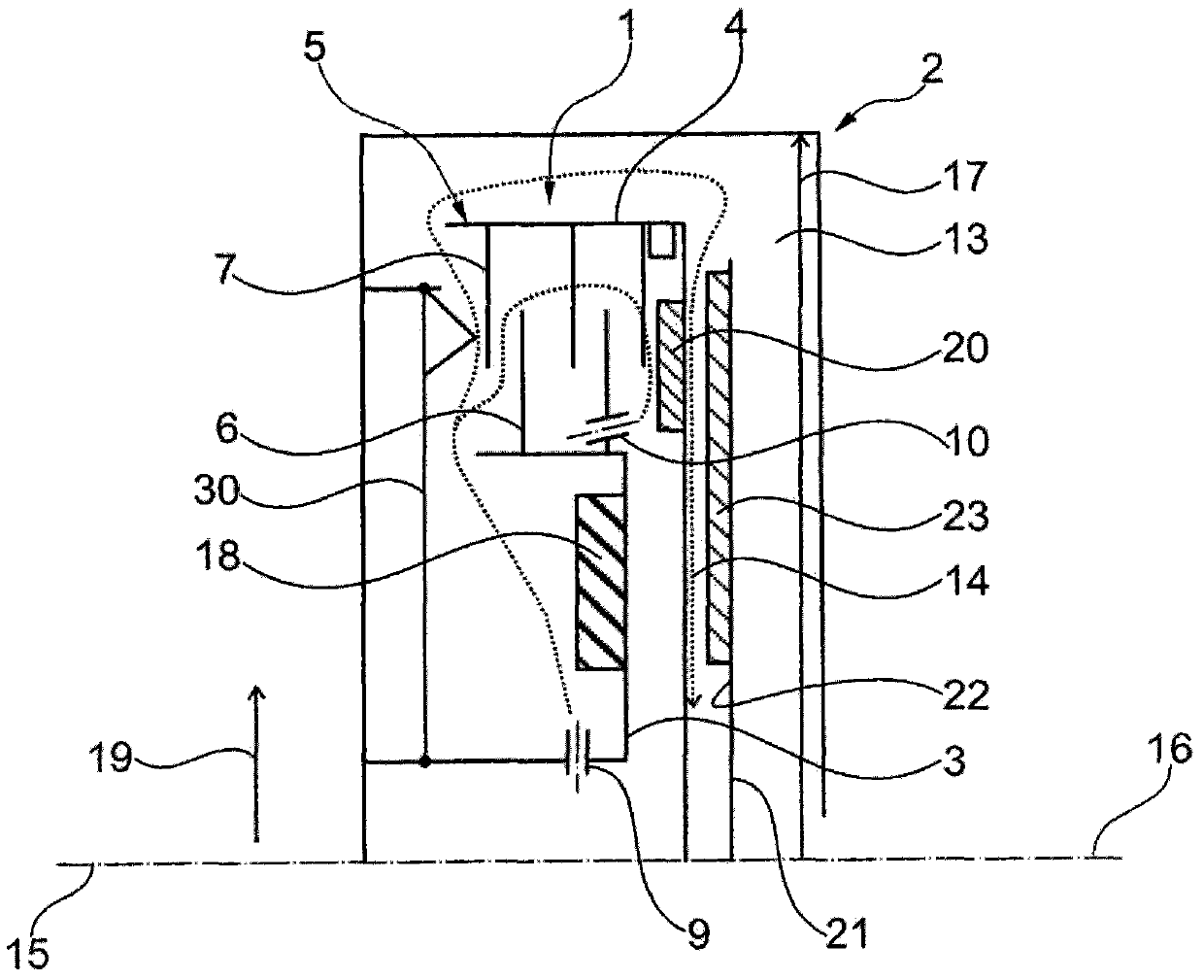

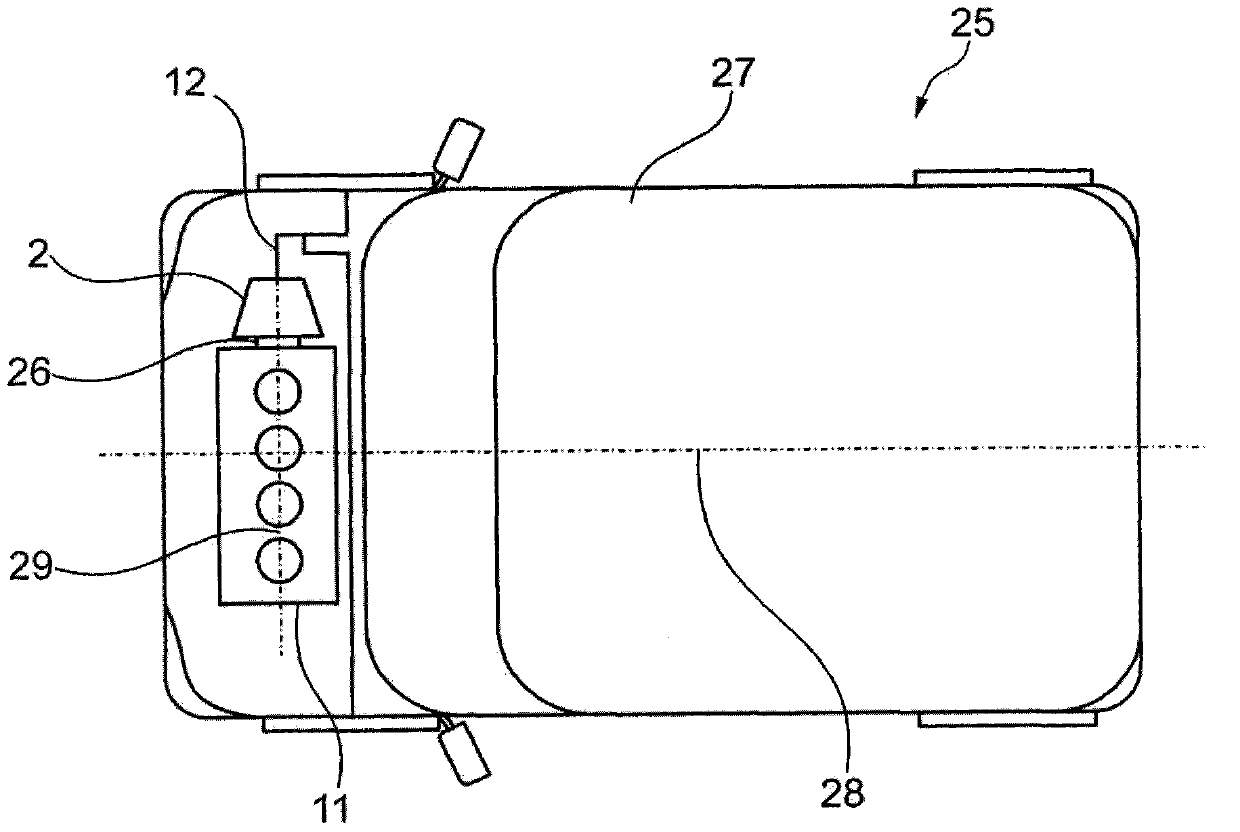

[0044] figure 1 is a sectional view of a wet friction clutch 2 comprising a friction pack 1 consisting of an inner disc carrier 3 and an outer disc carrier 4 . The inner disk carrier 3 and the outer disk carrier 4 each have a plurality of first disks 6 and second disks 7 . The first friction plate 6 and the second friction plate 7 are located in the friction plate chamber 5 . Formed in the first lining carrier 3 is a first through-opening 9 through which coolant can enter, pass through the first lining carrier 6 and the second lining 7 and return along the outer lining carrier 4 and again through the second lining carrier Two through openings 10 enter the friction lining chamber 5 . A feed line 24 to the friction lining chamber 5 , which is statically sealed by a first static seal 31 and a second seal 32 , is connected to the first through-opening 9 . In the partial schematic view of the wet friction clutch 2 , only the central shaft 8 is schematically shown, around which t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com