Preparation method of silicon nitride powder

A technology of silicon nitride powder and silicon powder is applied in the field of preparation of silicon nitride powder, which can solve the problems of difficult production management, many processes, and many equipment, and achieves long preheating time, reasonable connection relationship and high thermal power. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

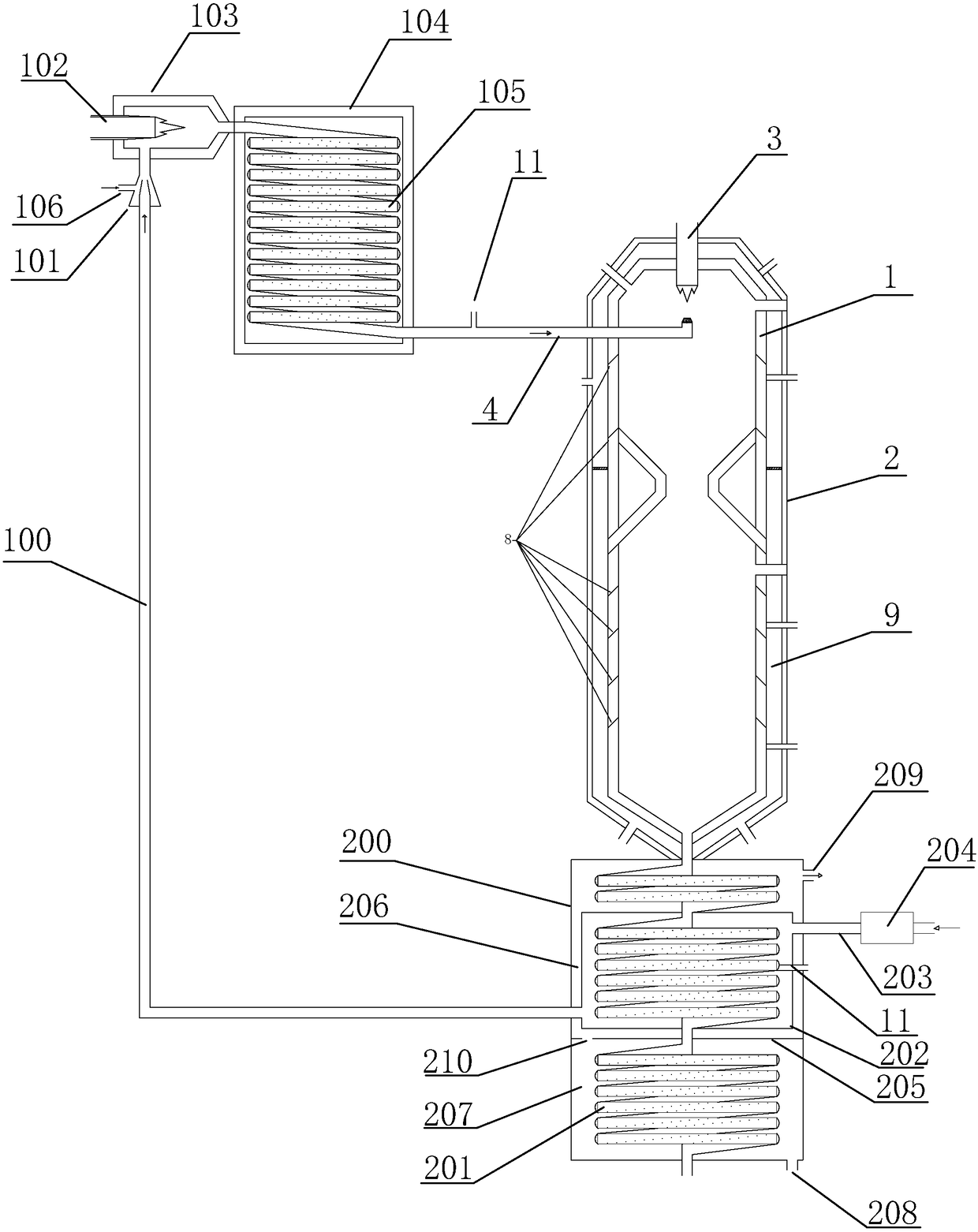

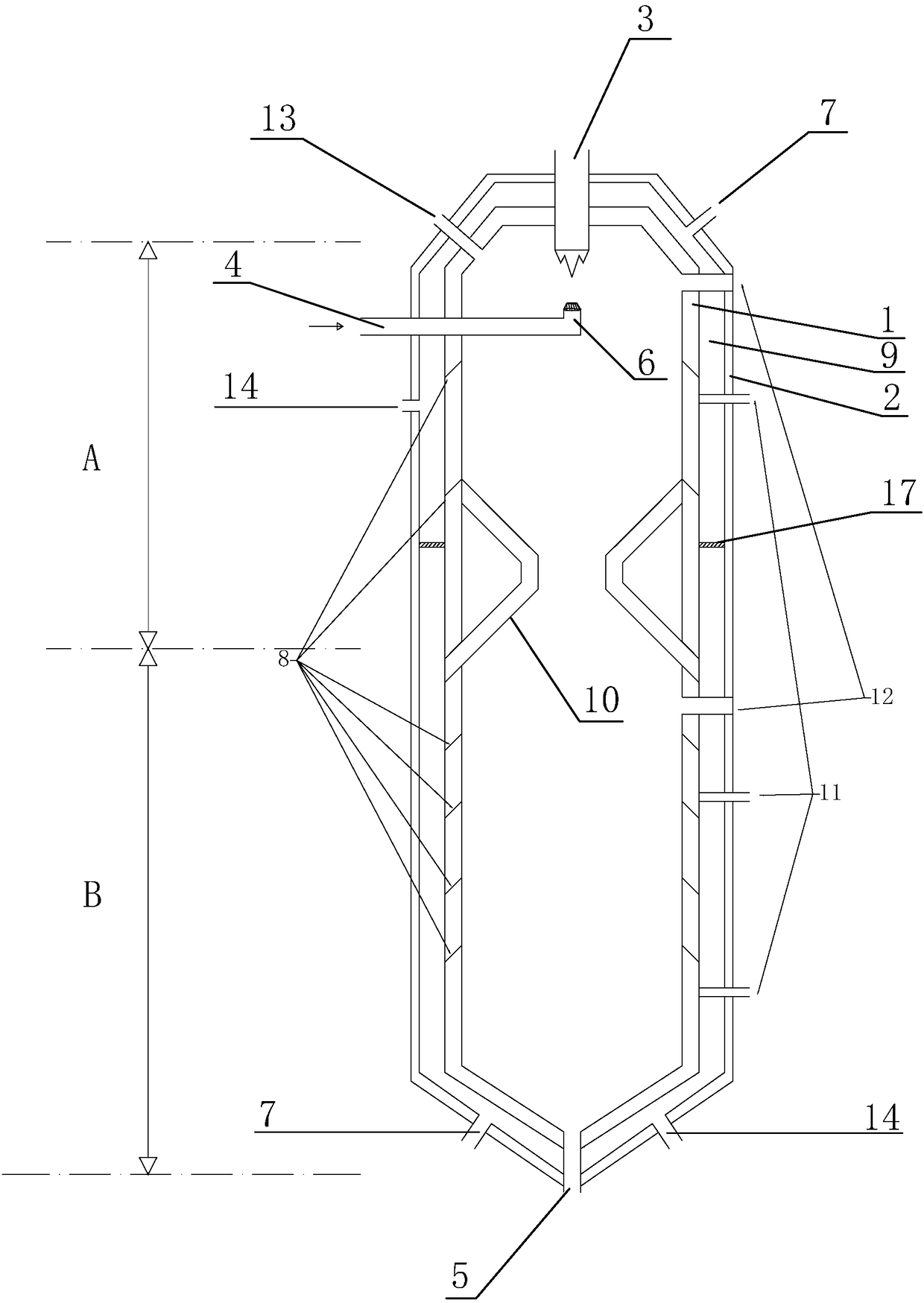

[0111] A preparation method of silicon nitride powder, comprising the following steps:

[0112] 1) Equipment preheating: heat the coil in the microwave plasma preheater and the inner chamber of the suspension reactor to 800-850°C and 1350-1400°C respectively with a microwave plasma torch.

[0113] 2) Material heating: Silicon powder (purity 99.99%, feed rate 1.2-1.8g / s, particle size 0.8-1.2vm), ammonia gas (purity 99.999%, flow rate 0.5-1cm 3 / s), nitrogen (purity 99.999%, flow 18-22cm 3 / s) The mixture is passed into the coil of the microwave plasma preheater for mixing and preheating to 700-750°C. The residence time of the mixture of silicon powder and ammonia and nitrogen in the coil is 50-60 seconds. Then the material is passed into the heating zone of the suspension reactor inner chamber in the form of upward spraying to form an inverted conical aerosol to continue heating; simultaneously, an upward nitrogen vortex flow is passed into the heating zone (flow rate is 10-...

Embodiment 1

[0118] A preparation method of silicon nitride powder, comprising the following steps:

[0119] 1) Equipment preheating: Heat the coil in the microwave plasma preheater and the inner cavity of the suspension reactor to about 825°C and 1375°C respectively with a microwave plasma torch.

[0120] 2) Material heating: silicon powder (purity 99.99%, feeding about 1.5g / s, particle size about 1vm) and ammonia gas (purity 99.999%, flow rate 0.75cm 3 / s), nitrogen (purity 99.999%, flow rate 20cm 3 / s) into the coil of the microwave plasma preheater for mixing and preheating to about 725°C. The residence time of the mixture of silicon powder and ammonia and nitrogen in the coil is about 55 seconds. Then the material is passed into the heating zone of the inner chamber of the suspension reactor in the form of upward spraying to form an inverted conical aerosol to continue heating; 3 / s or so, the pressure is maintained at 1.45-1.5 kPa) to drive the material to rotate. The residence t...

Embodiment 2

[0138] A preparation method of silicon nitride powder, comprising the following steps:

[0139] 1) Equipment preheating: Heat the coil in the microwave plasma preheater and the inner cavity of the suspension reactor to about 800°C and 1350°C respectively with a microwave plasma torch.

[0140] 2) Material heating: silicon powder (purity 99.99%, feed rate 1.8g / s, particle size about 0.8vm) and ammonia gas (purity 99.999%, flow rate 0.5cm 3 / s), nitrogen (purity 99.999%, flow rate 18cm 3 / s) into the coil of the microwave plasma preheater for mixing and preheating to about 700°C. The residence time of the mixture of silicon powder and ammonia and nitrogen in the coil is about 50 seconds. Then the material is passed into the heating zone of the suspension reactor inner chamber in the form of upward spraying to form an inverted conical aerosol to continue heating; simultaneously, an upward nitrogen vortex flow is passed into the heating zone (flow rate is 10cm 3 / s or so, the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com