Fin type non-corrosive steel alloy foil tube heat-exchanger and its manufacture method

A production method, stainless steel technology, applied to tubular components, manufacturing tools, heat exchange equipment, etc., can solve problems such as bottlenecks, high prices, and lack of copper resources, and achieve the effects of scientific design, reasonable structure, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

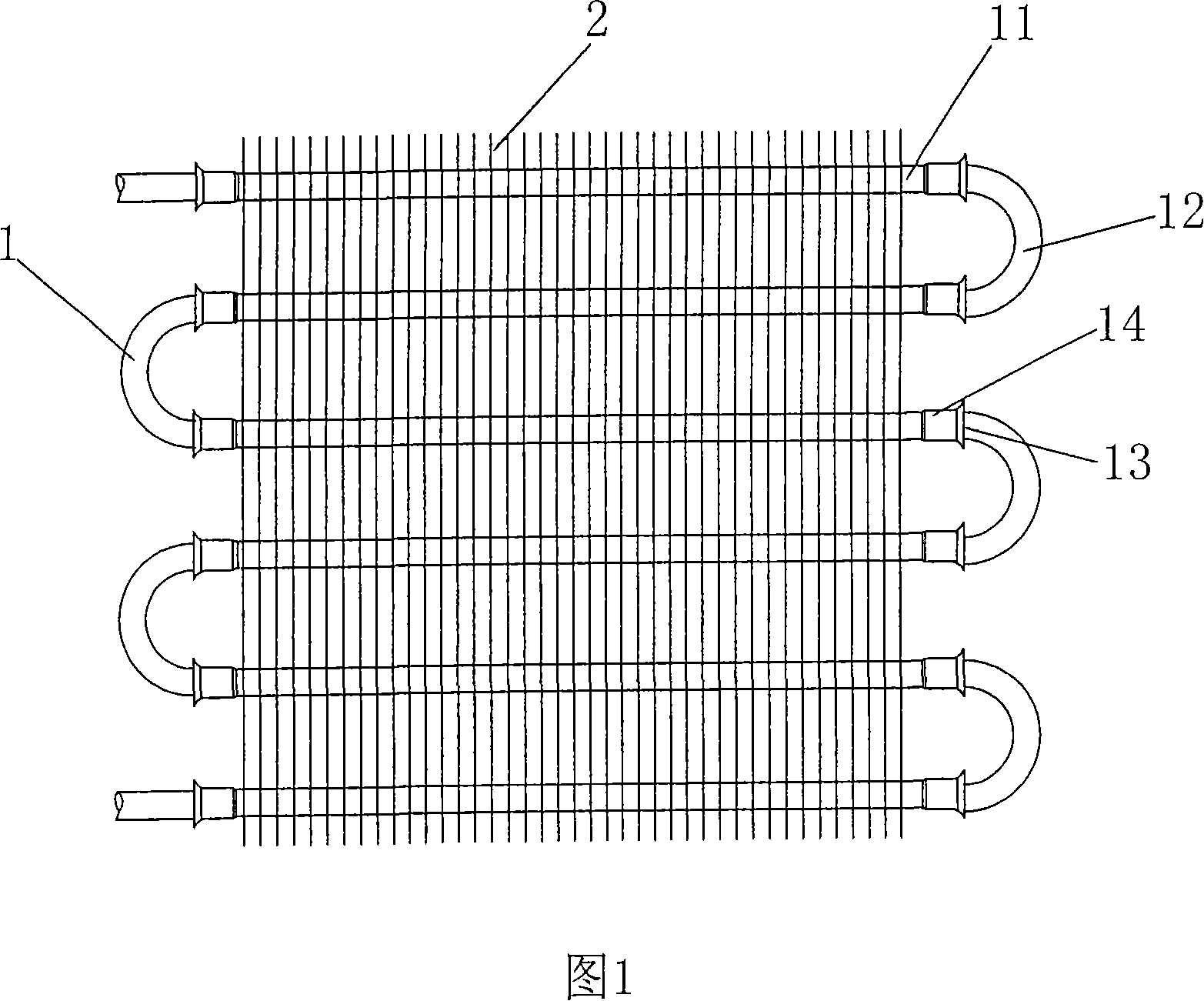

[0023] Embodiment 1: It can be clearly seen from Fig. 1 that the finned stainless steel alloy foil tube heat exchanger is composed of a stainless steel alloy foil coil tube 1 and a stainless steel alloy foil fin 2 with a tube wall thickness of 0.1 mm to 0.3 mm. The stainless steel alloy foil coil tube 1 is composed of six stainless steel alloy foil straight tubes 11 with a tube wall thickness of 0.15 mm and five stainless steel alloy foil U-shaped tubes 12 with a tube wall thickness of 0.3 mm; the two stainless steel alloy foil straight tubes 11 are The end parts are all provided with a cup mouth 14 with a bell mouth 13 for the insertion of the butt pipe. The stainless steel alloy foil fins 2 are all provided with through holes for the stainless steel alloy foil straight pipes 11 to be placed in series; the stainless steel alloy foil fins 2 arranged at intervals are fixedly installed on the stainless steel alloy foil straight pipes 11 arranged at intervals, through The stainle...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tube wall thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com