Three-valve hot-air engine

A hot gas engine and gas compressor technology, applied in hot gas variable displacement engine devices, machines/engines, mechanical equipment, etc., can solve problems such as heat loss and low fuel efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

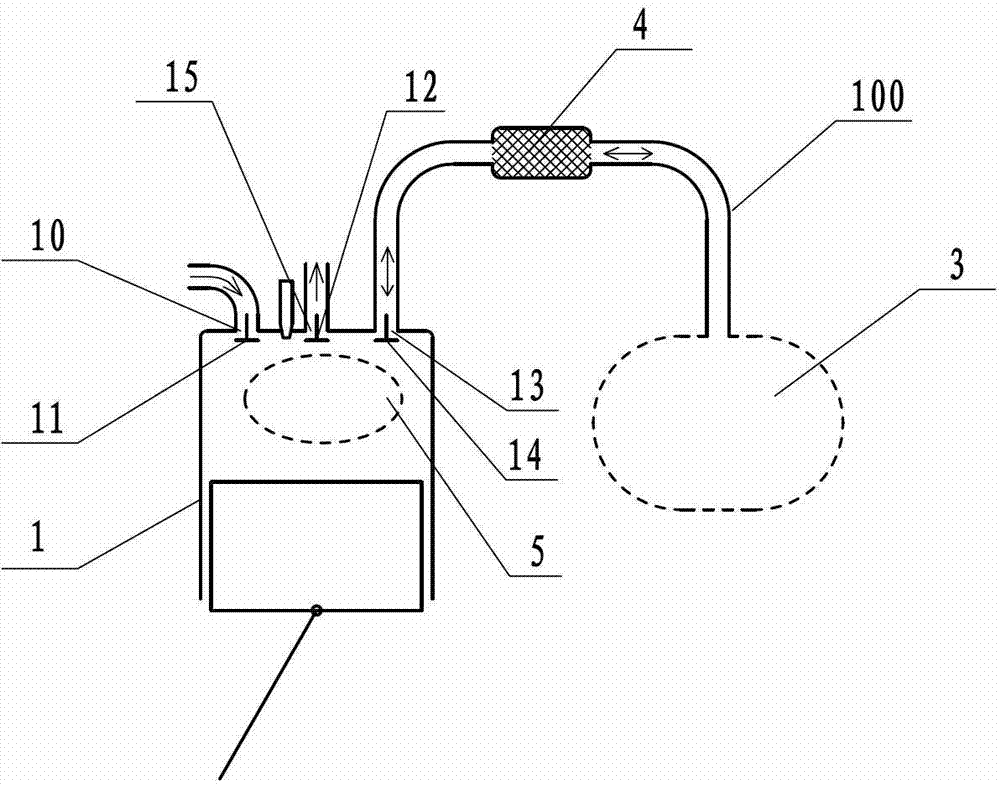

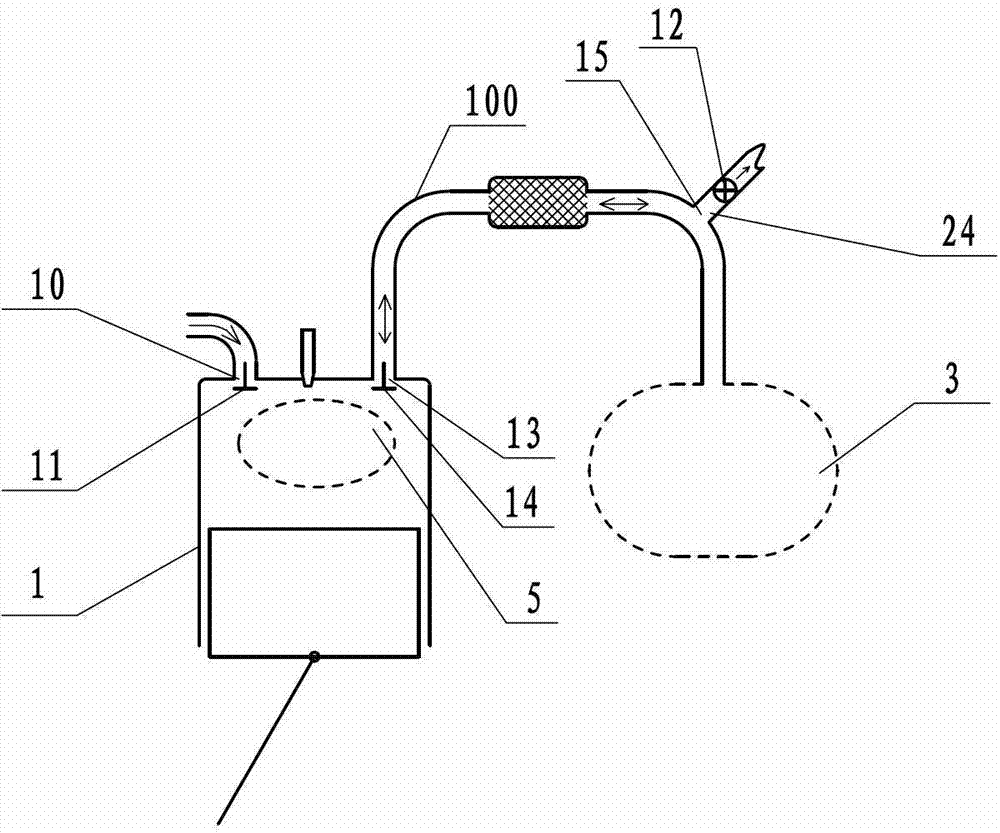

[0118] Such as image 3 The shown three-door hot gas engine comprises a cylinder-piston mechanism 1 and a combustion chamber 5, and the combustion chamber 5 is arranged in the cylinder-piston mechanism 1; an air inlet 10 is provided on the cylinder-piston mechanism 1, and the The air inlet 10 is provided with an intake valve 11, and the cylinder-piston mechanism 1 is provided with a reciprocating flow port 13, and the reciprocating flow port 13 is provided with a reciprocating flow control door 14; the cylinder-piston mechanism 1 is provided with The exhaust gas outlet 15 is provided with a exhaust valve 12, and the reciprocating flow port 13 communicates with the timing pulse gas mechanism 3 through the reciprocating communication channel 100, and the reciprocating communication channel 100 is provided with a heat recovery The regenerator 4 is equivalent to that the regenerator 4 communicates with the reciprocating flow port 13 at one end of the reciprocating communication ch...

Embodiment 2

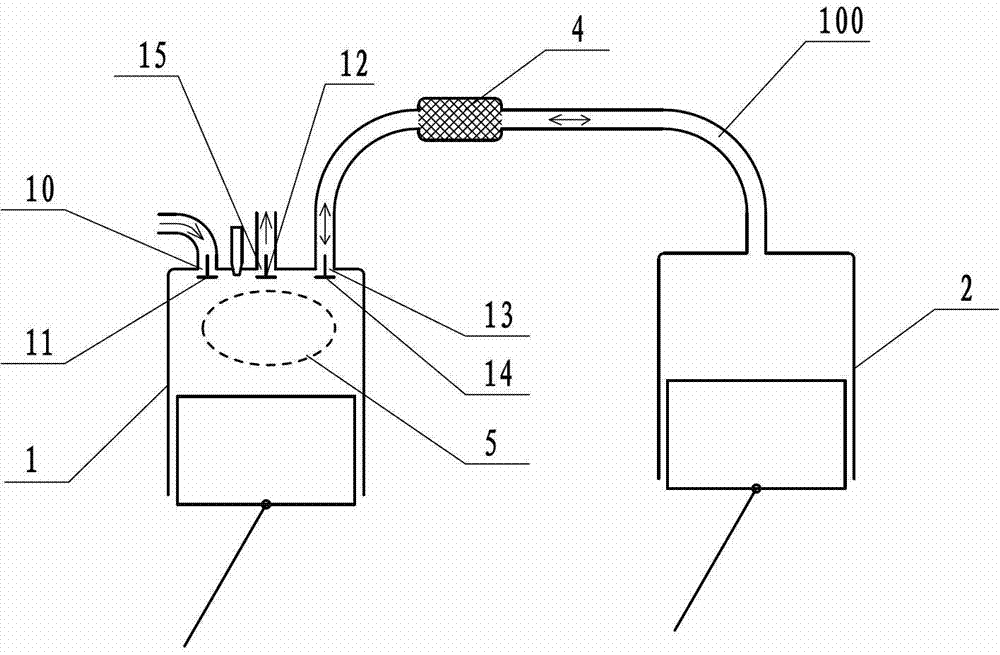

[0122] Such as Figure 4 The difference between the three types of door hot gas engines shown in Embodiment 1 is that a cooler 25 is provided on the auxiliary cylinder-piston mechanism 2 as the timing pulse gas mechanism 3, and a cooler 25 is installed on the regenerator A cooler 25 is also provided on the reciprocating communication passage 100 between 4 and the auxiliary cylinder-piston mechanism 2 .

[0123] Optionally, only any one of the above two coolers 25 may be provided.

[0124] Wherein, the highest pulse air pressure in the auxiliary cylinder-piston mechanism 2 as the timing pulse gas mechanism 3 is 0.8MPa.

Embodiment 3

[0126] Such as Figure 5 The difference between the three types of door hot gas engines shown in Embodiment 1 is that the timing pulse gas mechanism 3 is set as an air storage tank 301 with a timing control mechanism 6, and the regenerator 4 passes through the The timing control mechanism 6 communicates with the gas storage tank 301 . Under the control of the timing control mechanism 6, the gas storage tank 21 sends gas into the cylinder of the cylinder-piston mechanism 1 of the three-type door hot gas engine according to the timing relationship, and receives the gas according to the timing relationship. Describe the gas in the cylinder of the cylinder-piston mechanism 1 to ensure that the engine can work according to the six-stroke cycle mode of intake stroke-compression stroke-combustion explosion power stroke-air supply stroke-recharge power stroke-exhaust stroke.

[0127] Wherein, the highest pulse pressure in the air storage tank 301 is 1 MPa.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com