Heat pipe core, heat pipe and sputtering process of heat pipe

A sputtering process and heat pipe technology, applied in the direction of tubular elements, indirect heat exchangers, heat exchange equipment, etc., can solve the problems of high heat conduction power loss ratio, low efficiency, large temperature difference between cold and hot ends, etc., and achieve detailed selection Specifications, increased heat conduction power, and reduced temperature difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to understand the technical content of the present invention more clearly, the following examples are given in detail, the purpose of which is only to better understand the content of the present invention but not to limit the protection scope of the present invention. The components in the structures in the drawings of the embodiments are not scaled according to the normal scale, so they do not represent the actual relative sizes of the structures in the embodiments.

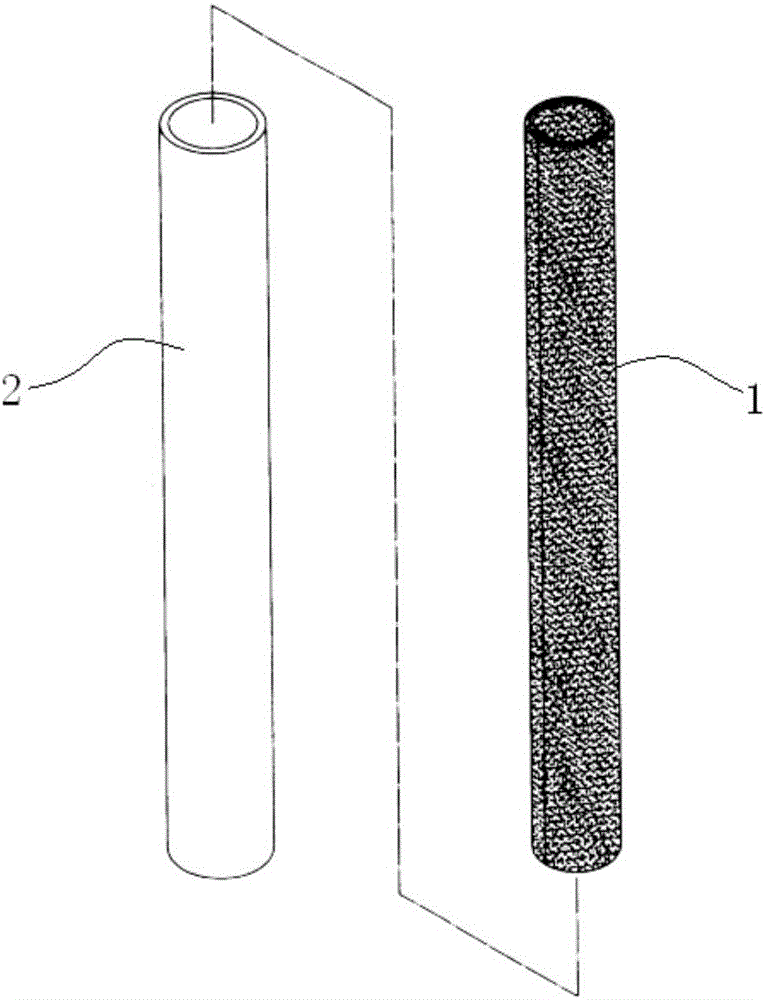

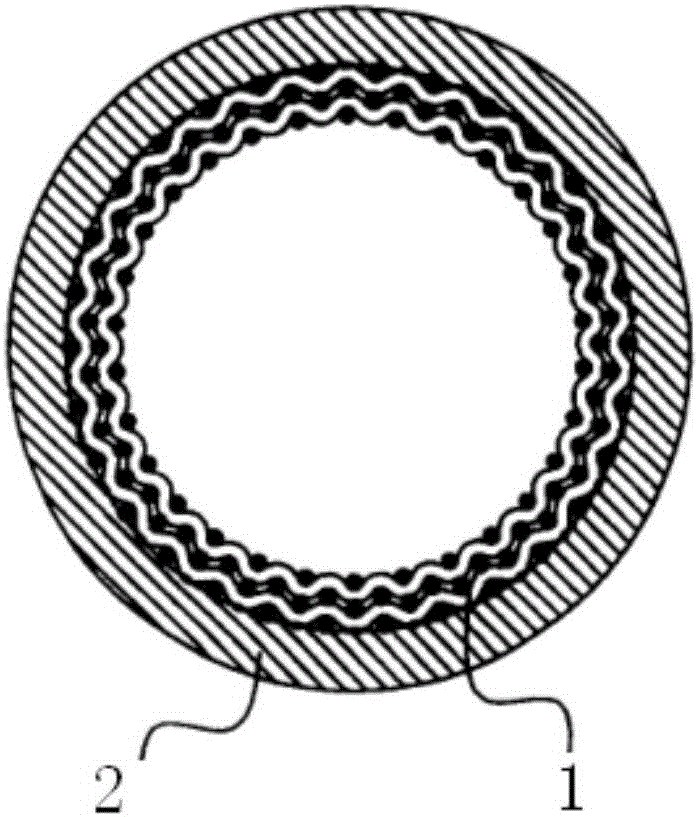

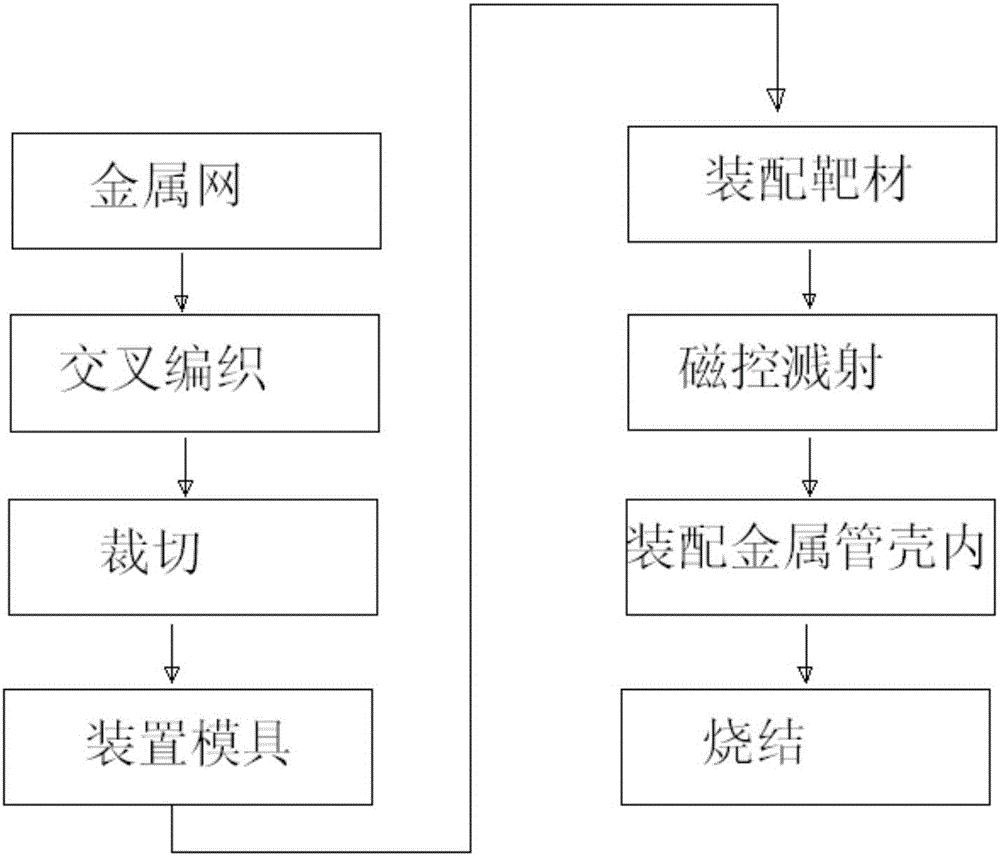

[0026] Such as figure 1 As shown, a heat pipe core 1 includes a single-layer, double-layer or more than two-layer sheet metal mesh, and the surface of the sheet metal mesh is sputtered with at least one layer of sputtering film made of graphene. When the sheet metal mesh and the sputtering film are installed on the inner wall of the metal shell of the heat pipe, they are in the shape of a circumferential butt joint pipe. In this way, a layer of graphene material is sputtered on the surface of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com