Reactor and method of processing a semiconductor substrate

a technology of semiconductor substrate and reaction chamber, which is applied in the direction of heat measurement, optical radiation measurement, instruments, etc., can solve the problems of reducing the strength of the substrate, affecting the accuracy and the use of contact probes such as thermocouples or resistance wire thermometers, etc., to achieve accurate determination of the temperature of the substrate during processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

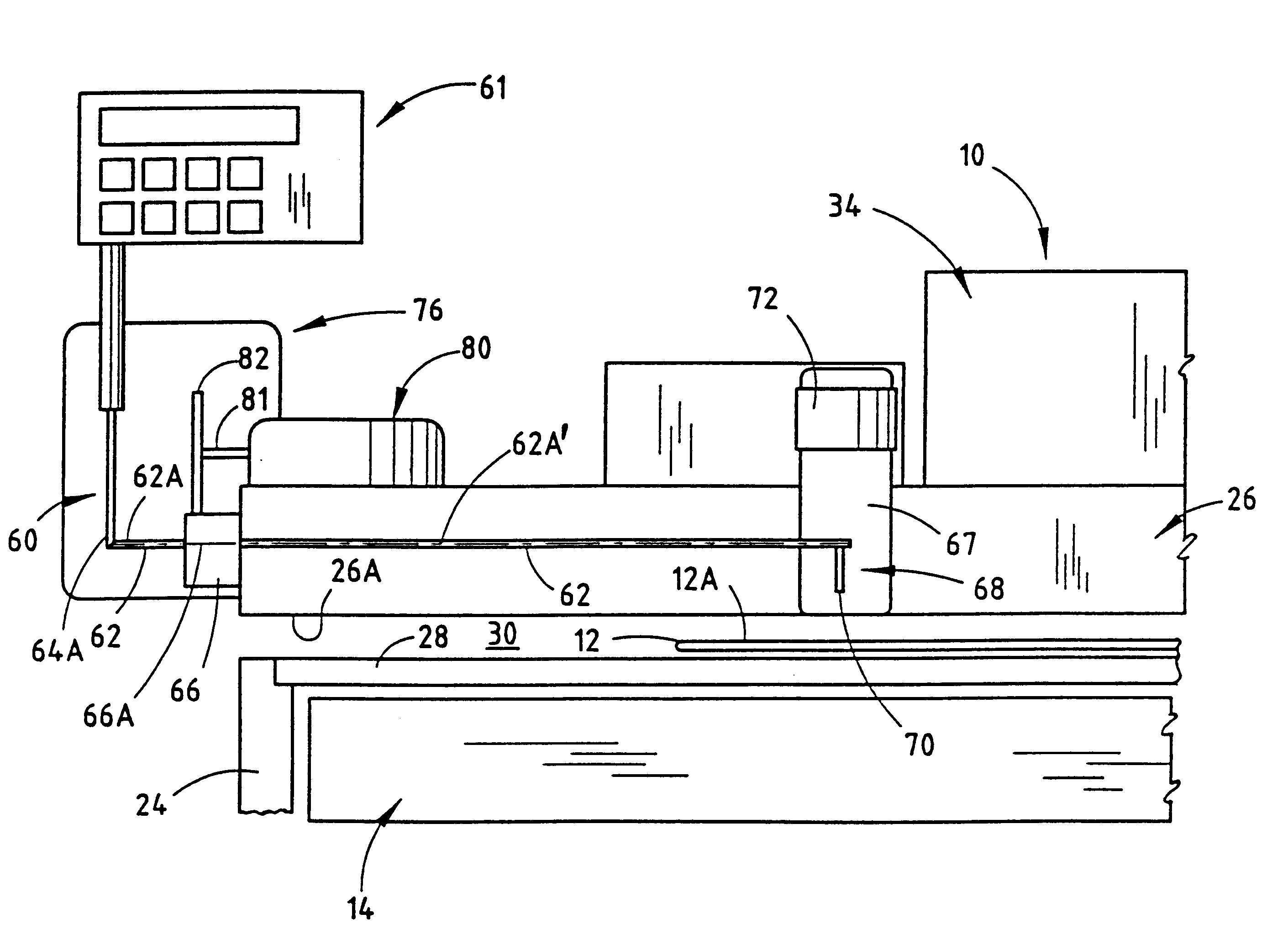

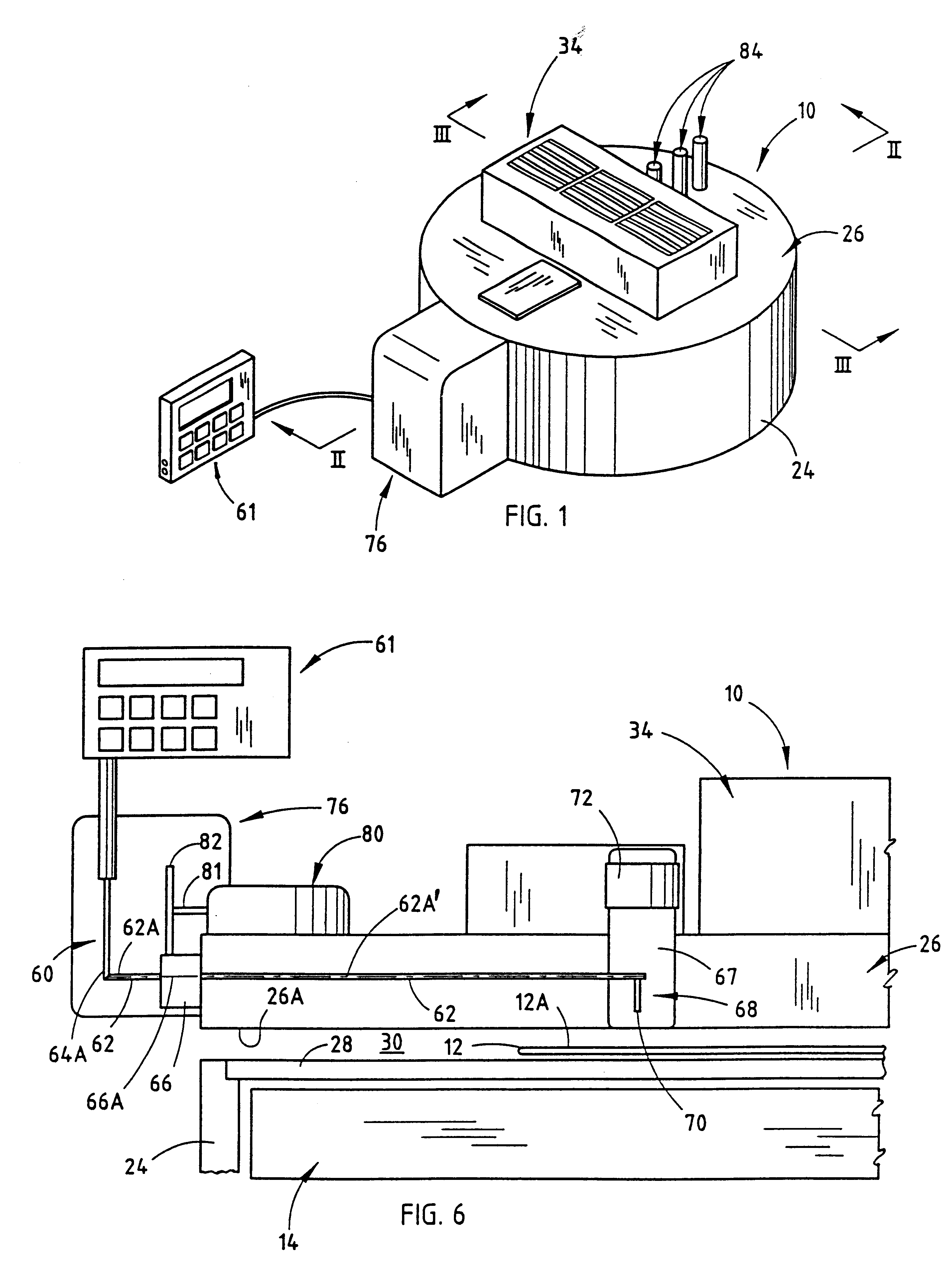

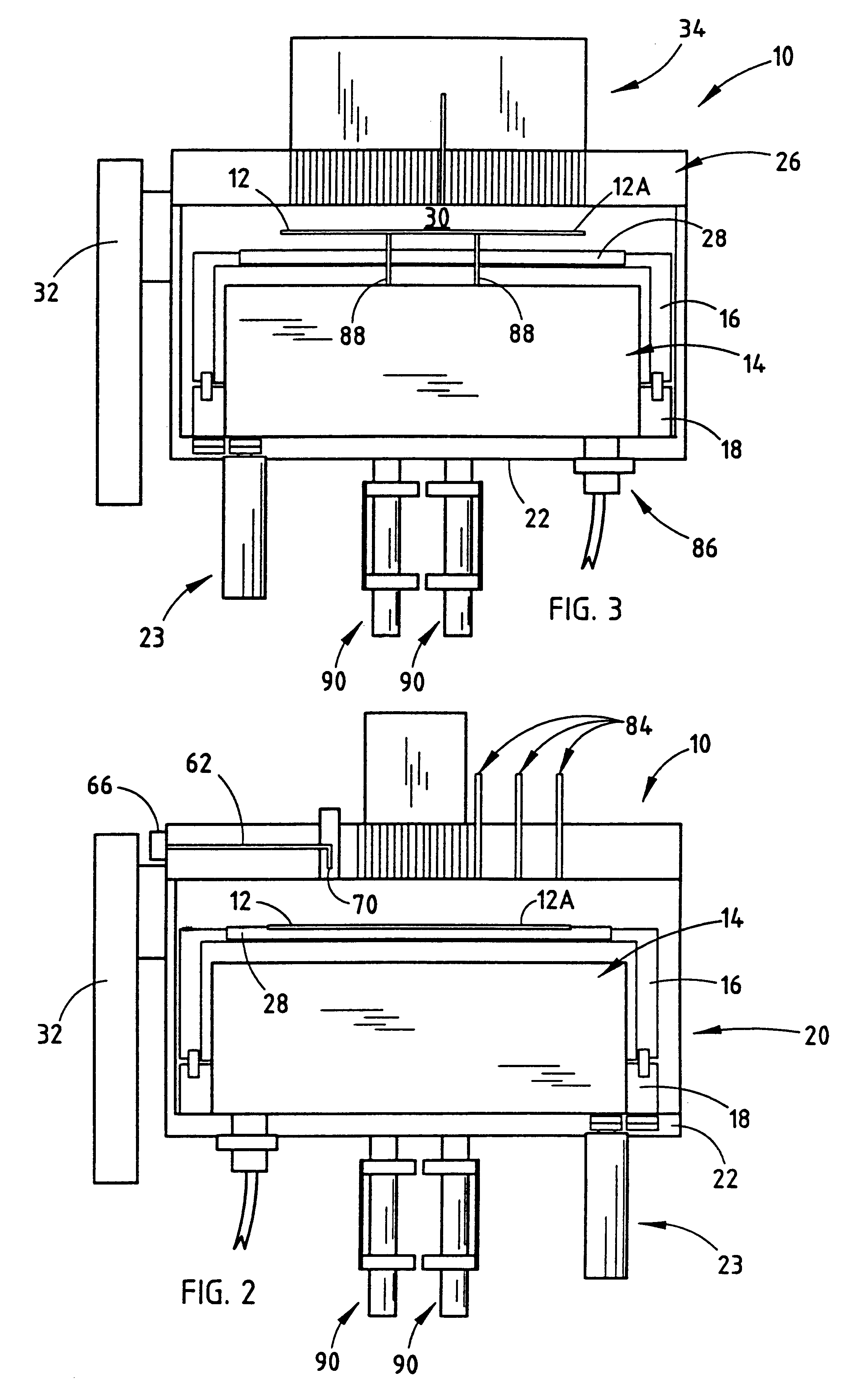

Referring now to the drawings and particular to FIGS. 1 and 2, a reactor for processing semiconductor substrates is generally indicated by the numeral 10. In the illustrated embodiment, reactor 10 comprises a single wafer processing reactor that is suitable for performing various fabrication processes on a semiconductor substrate 12, such as a semi-conductor wafer. Reactor 10 is particularly suitable for thermal processing of a semiconductor wafer. Such thermal processes include thermal annealing of a semiconductor wafer and thermal reflow of boro-phosphorous gasses, and chemical vapor deposition of thin film applications, such as high temperature oxide, low temperature oxide, high temperature nitride, doped and undoped polysilicon, silicon epitaxial and tungsten metal and tungsten silicide films, in the fabrication of a semiconductor device. The control of these processes depends on the control of gas flow, gas pressure, and wafer temperature. As will be described in more detail, r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Flow rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com