Planar passive micromixer

A mixer and passive technology, applied in mixers, chemical instruments and methods, dissolution, etc., can solve problems that are not conducive to mass production and large-scale application, high production cost, complex structure, etc., and achieve simple structure and easy processing , low-cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

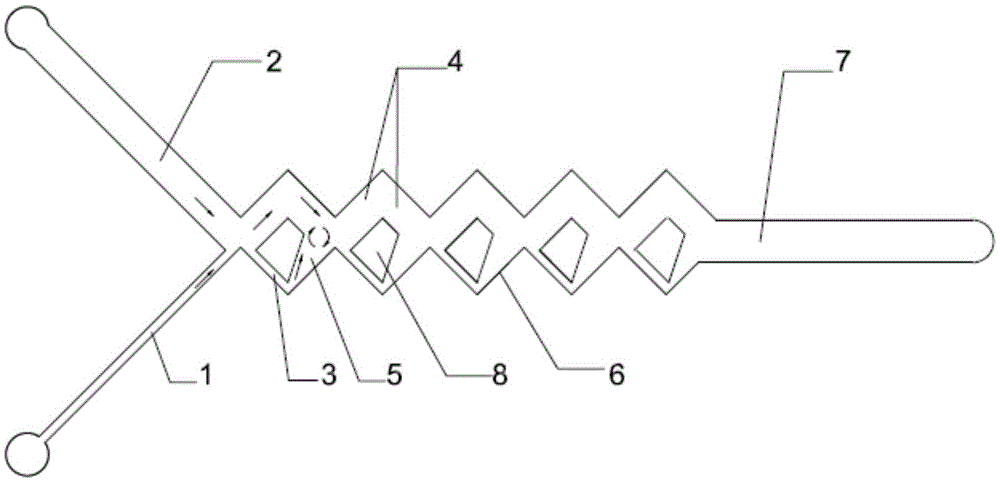

[0033] Such as figure 1 Shown, a kind of planar passive micro-mixer, the cross-section of the first inlet channel and the second inlet channel is rectangular, the first inlet channel 1 and the second inlet channel 2 are vertical, converging at the intersection of the mixing unit 6, The mixing unit 6 here is a cavity surrounded by quadrangular side walls. There is a stopper 8 in the mixing unit 6. The stopper 8 separates the mixing unit 6 into a first split channel 3, a second split channel 4 and a mixed flow channel. The cavity 5, the first flow channel 3 and the second flow channel 4 communicate with the intersection of the mixing unit 6, and the flow mixing cavity 5 communicates with the first flow channel 3 and the second flow channel 4 of the adjacent mixing unit. And it is located at the outlet of the mixing chamber 5 .

[0034] The cross section of the stopper 8 here is a right-angled trapezoid, and the mixed flow chamber 5 formed by the separation matches the shape of ...

Embodiment 2

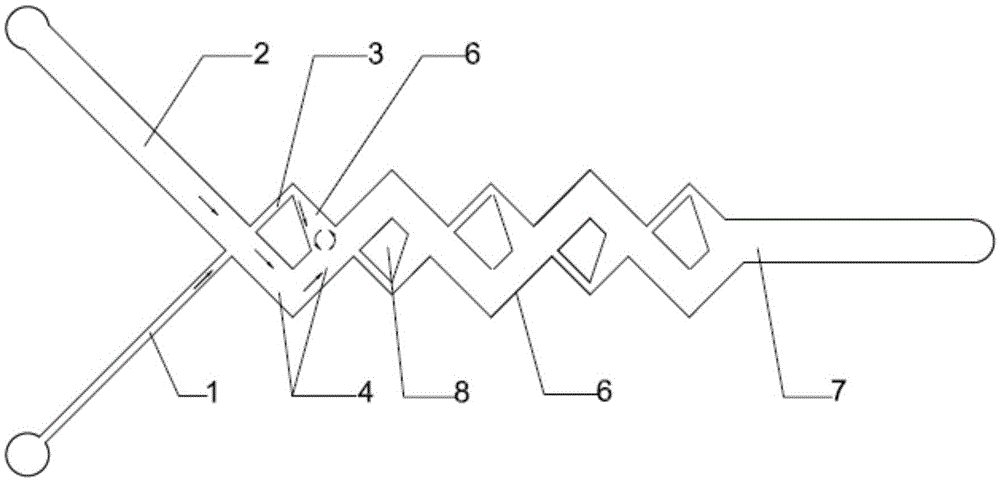

[0037] Such as figure 2 As shown, the second embodiment is basically similar to the first embodiment, but different from the first embodiment, the shape of the stopper 8 in each mixing unit 6 is the same, and the mixing unit 6 includes first alternately arranged The mixing unit and the second mixing unit; the stoppers in the first mixing unit are set differently from the stoppers in the second mixing unit. Of course, the arrangement direction can also be random, as long as the mixing chamber 5 of the mixing unit 6 communicates with the first flow channel 3 and the second flow channel 4 in the adjacent mixing unit 6, and is located at the outlet of the mixing unit 6, that is Can.

Embodiment 3

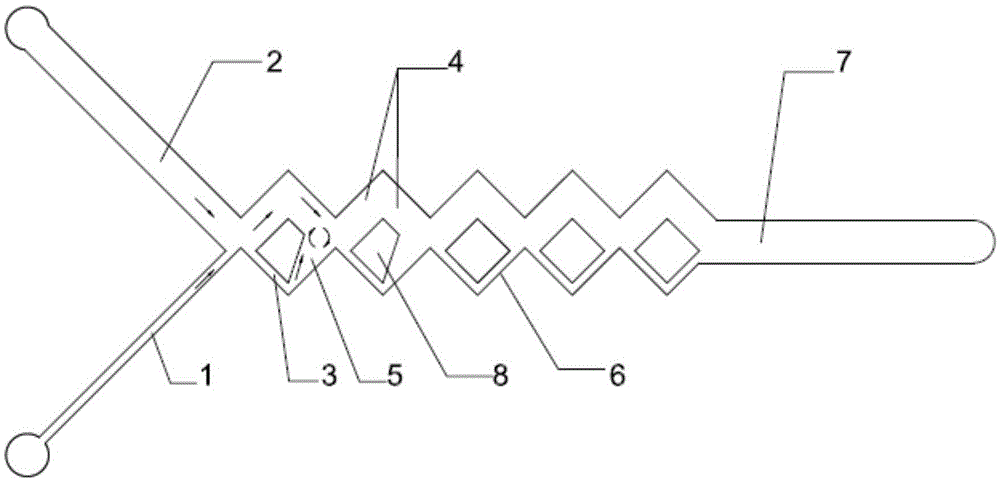

[0039] Such as image 3As shown, the third embodiment is basically similar to the first embodiment, but different from the first embodiment, the cross-section of some stoppers 8 is a right-angled trapezoid, and the cross-section of some stoppers 8 is a square, which are separated to form The mixed flow chamber 5 matches the shape of the stopper 8. When the cross section of the stopper 8 is a right-angled trapezoid, the mixed flow chamber 5 is a trapezoidal cavity, and the width of the mixed flow chamber gradually increases from the first flow channel to the second flow channel. widen. When the cross section of the block 8 is a square, the mixed flow chamber 5 is a rectangular cavity, and the width of the mixed flow chamber 5 is equal.

[0040] The shape of stopper 8 in each mixing unit 6 is different, and the cross section of stopper 8 is a right-angled trapezoid in the first mixing unit, and the cross-section of stopper 8 in the second mixing unit 6 is a right-angled trapezo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com