Patents

Literature

119results about How to "Suitable for large-scale production applications" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for extracting cyanidin from banana peel

InactiveCN102924423AHigh purityImprove qualityOrganic chemistryNatural dyesChemistryUltrarapid freezing

The invention discloses a method for extracting cyanidin from banana peel. A ultrasonic-assisted microbial fermentation method is utilized to extract cyanidin from green banana peel: a microbial fermentation method is utilized to destroy banana peel cell walls by using Aspergillus niger metabolite, and cavitation generated by ultrasonic is utilized to sufficiently release the cyanidin. Centrifugal slag-liquid separation, membrane filtration separation, chromatography purification, ultrarapid freezing, vacuum drying and the like are carried out to obtain the cyanidin of which the purity exceeds 94%. The ultrarapid freezing has the characteristics of good quality, small ice crystal, high drying rate and the like, and is widely used in food processing. The combination of the ultrarapid freezing and vacuum drying has the advantages of thorough dehydration in freezing state, low component loss, excellent quality and long storage time. The invention is simple to operate, has the advantages of high yield, high efficiency, clean and harmless generation process, small energy consumption, high benefit, high cyanidin yield and high purity, is suitable for large-scale production, and has wide market prospects.

Owner:杨公明

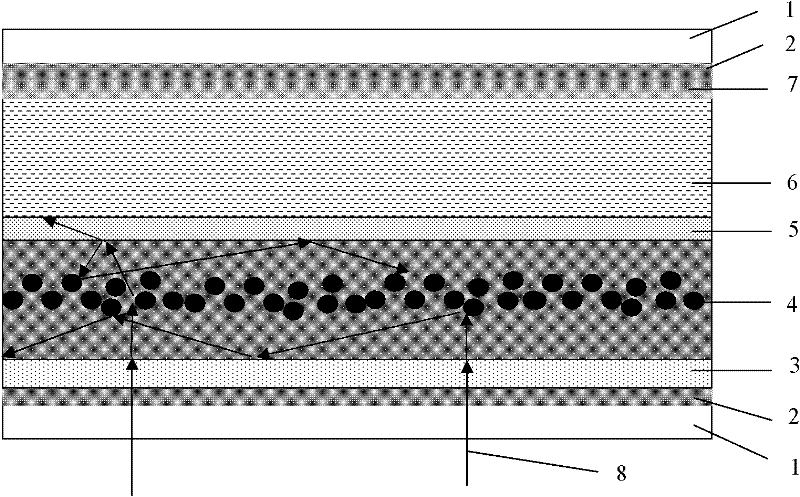

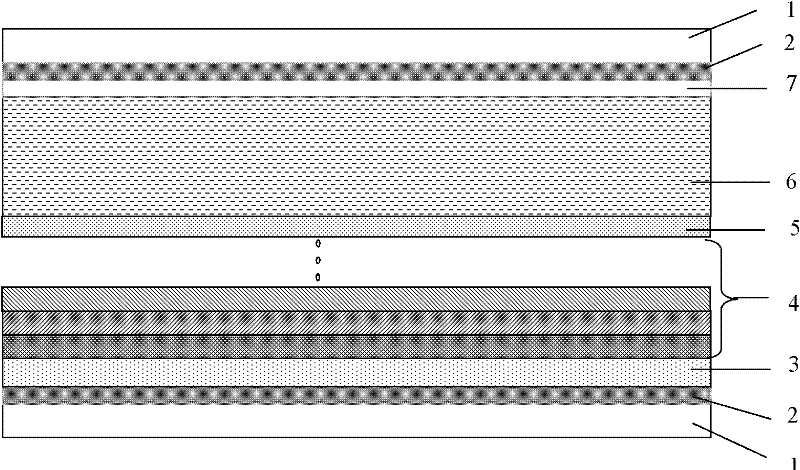

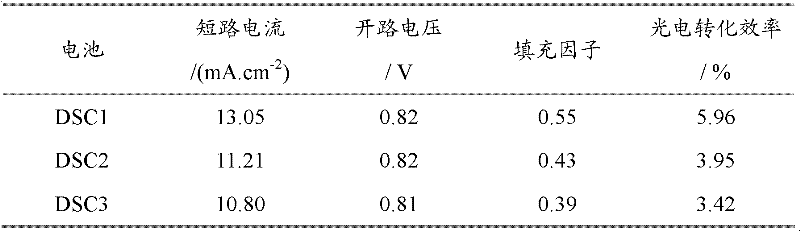

Dye-sensitized nanocrystalline thin film solar cell with light trapping structure

InactiveCN102254695AExtensive selection of preparation materialsPromote absorption and utilizationLight-sensitive devicesFinal product manufactureNanocrystalline thin filmsPhysics

The invention discloses a dye-sensitized nanocrystalline thin film solar cell with a light trapping structure. The dye-sensitized nanocrystalline thin film solar cell with the light trapping structure comprises a photo-anode, electrolyte and a counter electrode, wherein the photo-anode mainly comprises a conductive substrate and a nanocrystalline film; the nanocrystalline film consists of at least one layer of unit thin film; each layer of unit thin film is formed by laminating more than three layers of nanocrystalline thin films with different refractive indexes; and the light refractive indexes of the nanocrystalline thin films of the outmost layers on the two sides of the unit thin film are lower than the light refractive index of each nanocrystalline thin film of the inner layer of the unit thin film, and the light refractive indexes of each nanocrystalline thin film of the inner layer are gradually increased or gradually increased and then gradually decreased along a light projection direction. The cell provided by the invention fulfills the aim of trapping light by the scattering and complete reflection of light, is prepared from a wide range of materials by a simple preparation method, has a wide application range and can greatly enhance the light absorption and utilization of the thin films, thereby greatly optimizing the photoelectric conversion efficiency of the cell.

Owner:NANJING UNIV OF TECH

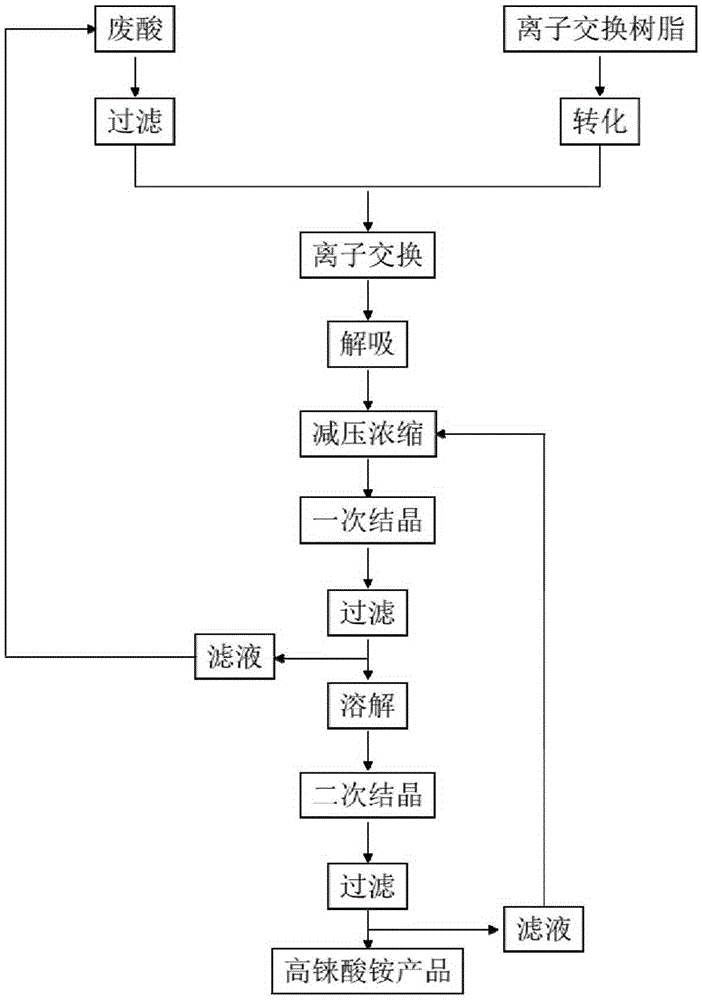

Method for recovering rhenium from molybdenum smelting waste acid

ActiveCN105384195ASimple recycling processSimple and efficient operationRhenium compounds preparationIon exchangeAmmonium sulfate

The invention discloses a method for recovering rhenium from molybdenum smelting waste acid and belongs to the technical field of metal rhenium recovery and recycle. The method comprises 1, filtering molybdenum smelting waste acid, and treating the filtrate by a composite aminoethylene weak basic anion exchange resin column for adsorption until adsorption is saturated, and 2, carrying out desorption on the saturated anion exchange resin column, collecting the desorption liquid and carrying out evaporation crystallization to obtain ammonium perrhenate. The composite aminoethylene weak basic anion exchange resin has large saturation adsorption quantity. The desorption liquid has rhenium content 100 times or more that of waste acid. Compared with the existing extraction method and ion exchange method, the method provided by the invention has a high rhenium recovery rate of 98% or more. Through use of solubility difference of ammonium perrhenate, ammonium molybdate and ammonium sulfate, ammonium perrhenate is purified by evaporation crystallization and ammonium perrhenate purity is 99.9% or more. The method has a simple rhenium recovery process, is environmentally friendly, is convenient for operation and is suitable for large scale production.

Owner:ZHENGZHOU MINERALS COMPOSITIVE UTILIZATION RES INST CHINESE GEOLOGICAL ACAD +1

Chinese patent drug for treatment of gouty arthritis

InactiveCN103127428AReliable curative effectComplete cureAntipyreticAnalgesicsGouty arthropathyRemove blood

The invention relates to a Chinese patent drug for treatment of gouty arthritis. The Chinese patent drug is prepared by semen coicis, rhizoma atractylodis, dioscorea and the like according to parts by weight, and has the beneficial effects that aiming at the three key factors causing gouty arthritis such as phlegm-damp, blood stasis and heat toxin, the Chinese patent drug adopts Chinese herbal medicine compound preparation having action of excreting dampness and reducing phlegm, promoting blood circulation to remove blood stasis, clearing and activating the channels and collaterals, diminishing inflammation and relieving pain, clearing away heat and toxic materials and removing uric acid, has reliable curative effects, can thoroughly cure the gouty arthritis, and has no toxic or side effect, and the gouty arthritis does not relapse for a long time; and if western medicine is adopted for treating gouty arthritis, the side effect is obvious, the gouty arthritis is easy to relapse, and the western medicine cannot be used for long time cure, while the Chinese patent drug has remarkable curative effect and is applicable to mass production, and a patient taking the drug has no discomfort.

Owner:谢银芳

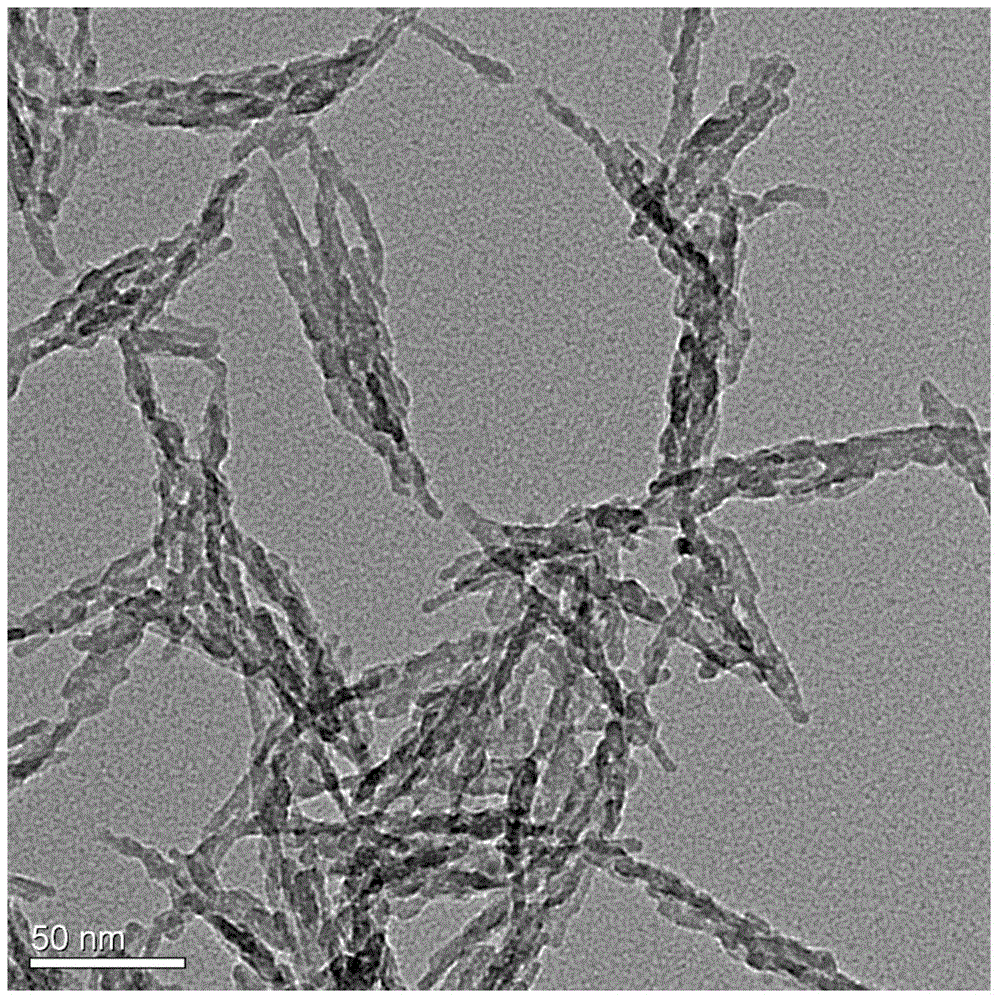

Carbon nano tube dispersion liquid and preparation method thereof

ActiveCN103700823AImprove consistencyImprove liquidityCell electrodesSecondary cellsCarbon nanotubeSolvent

The invention provides a carbon nano tube dispersion liquid and a preparation method of the carbon nano tube dispersion liquid. The carbon nano tube dispersion liquid comprises a carbon nano tube, a high conductivity carbon black, a dispersion agent and a solvent. The carbon nano tube dispersion liquid is uniform and stable, and also excellent in consistency, mobility, dispersion and glossiness, the high conductivity carbon black is in the dispersion liquid to further improve the performance of the carbon nano tube dispersion liquid, so that the application of the carbon nano tube dispersion liquid is more extensive. The carbon nano tube dispersion liquid can be dispersed only through being grinded by a regular grinding machine, the preparation of the carbon nano tube dispersion liquid is simpler and more practical, the dispersion is completed only through the cheap grinding machine in the preparation method, in addition, the yield is high, the safety performance is excellent, the operation is simple, the dispersion efficiency is high, the dispersion cost is greatly lowered, the production quality is improved, and the carbon nano tube dispersion liquid is more suitable for batch production as well as large-scale production and application.

Owner:SHENZHEN SSZK NEW MATERIALS CO LTD

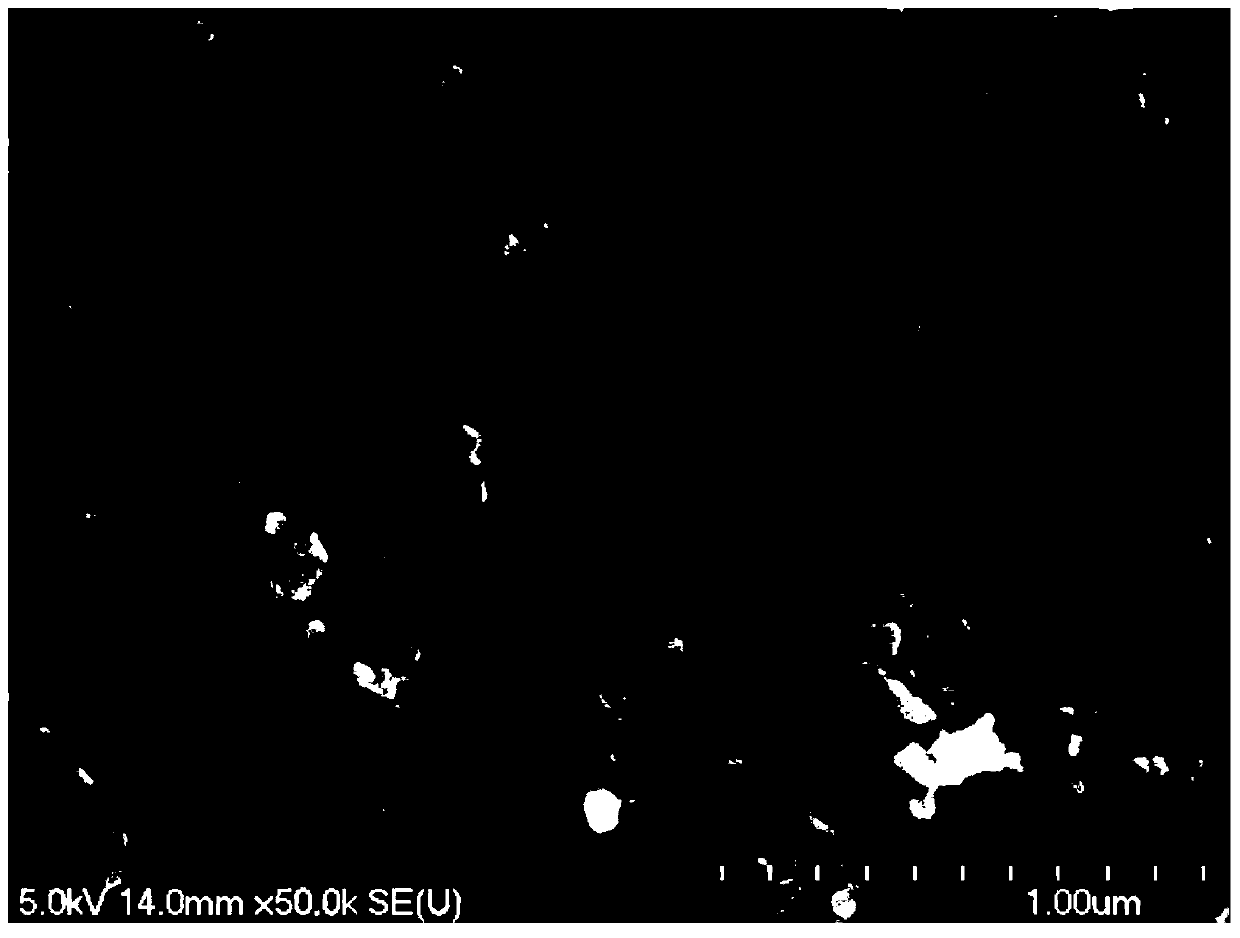

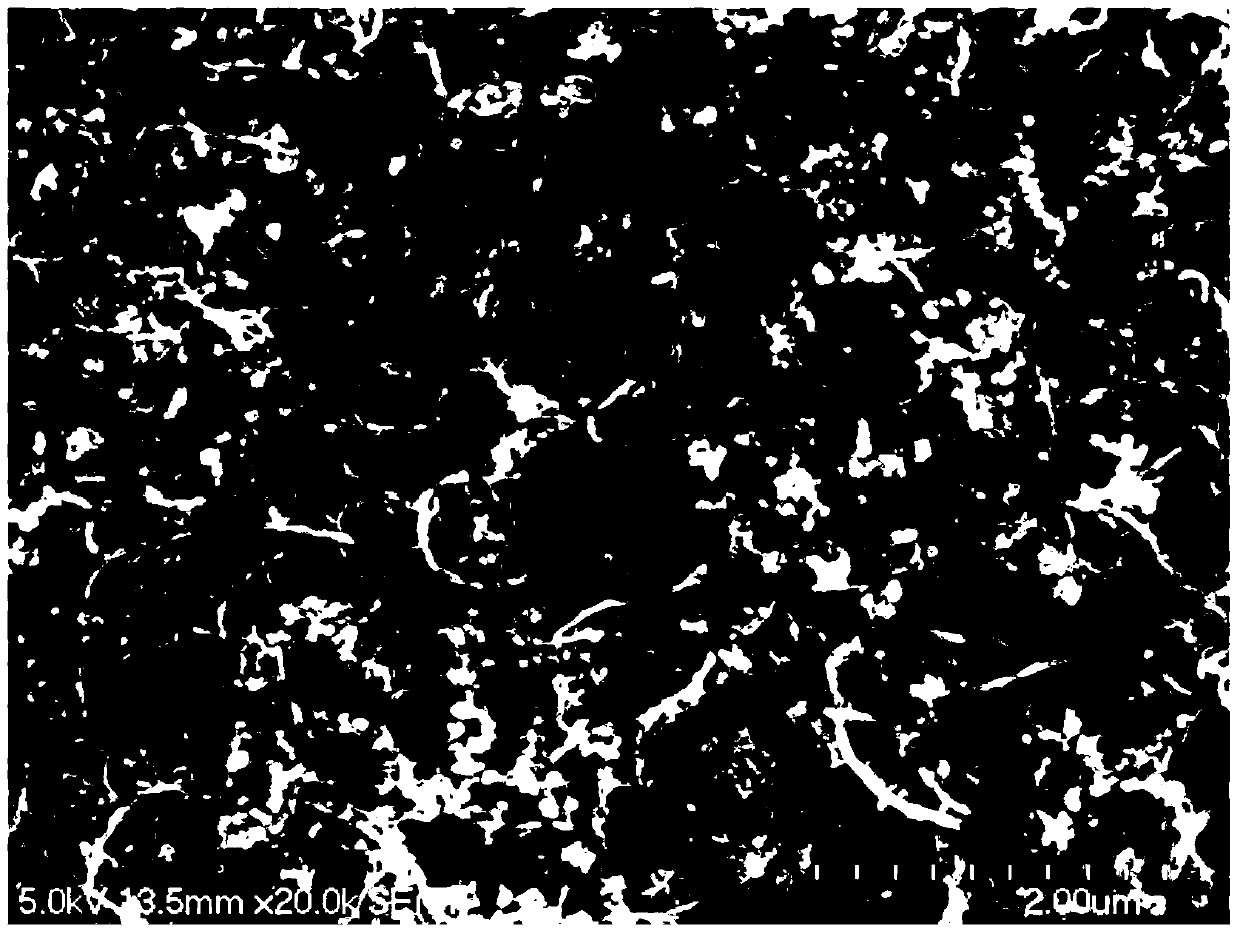

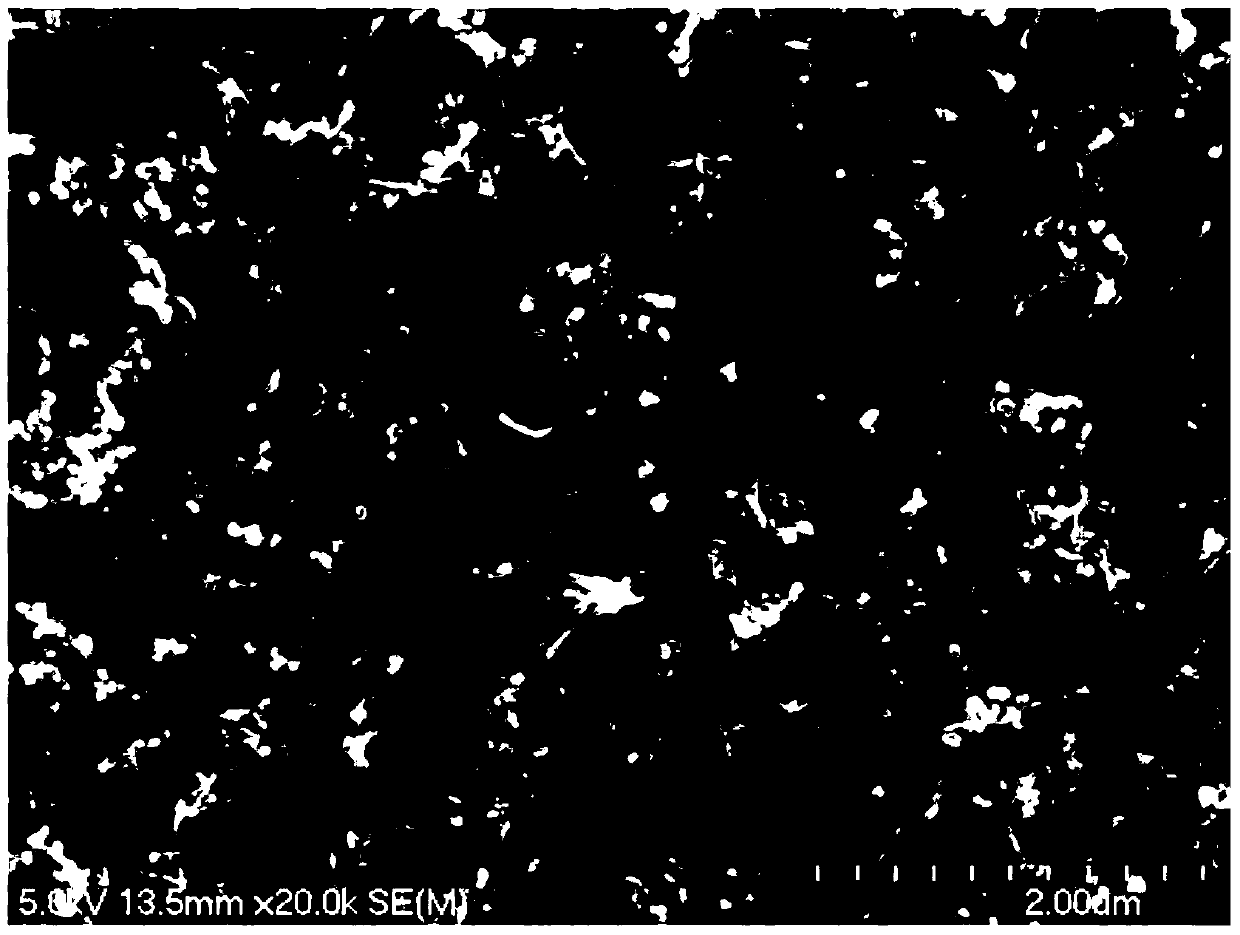

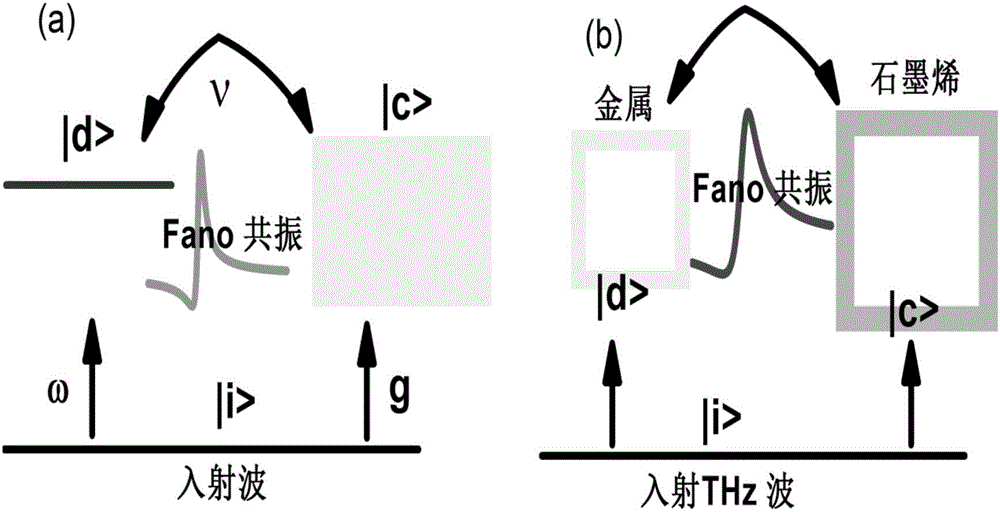

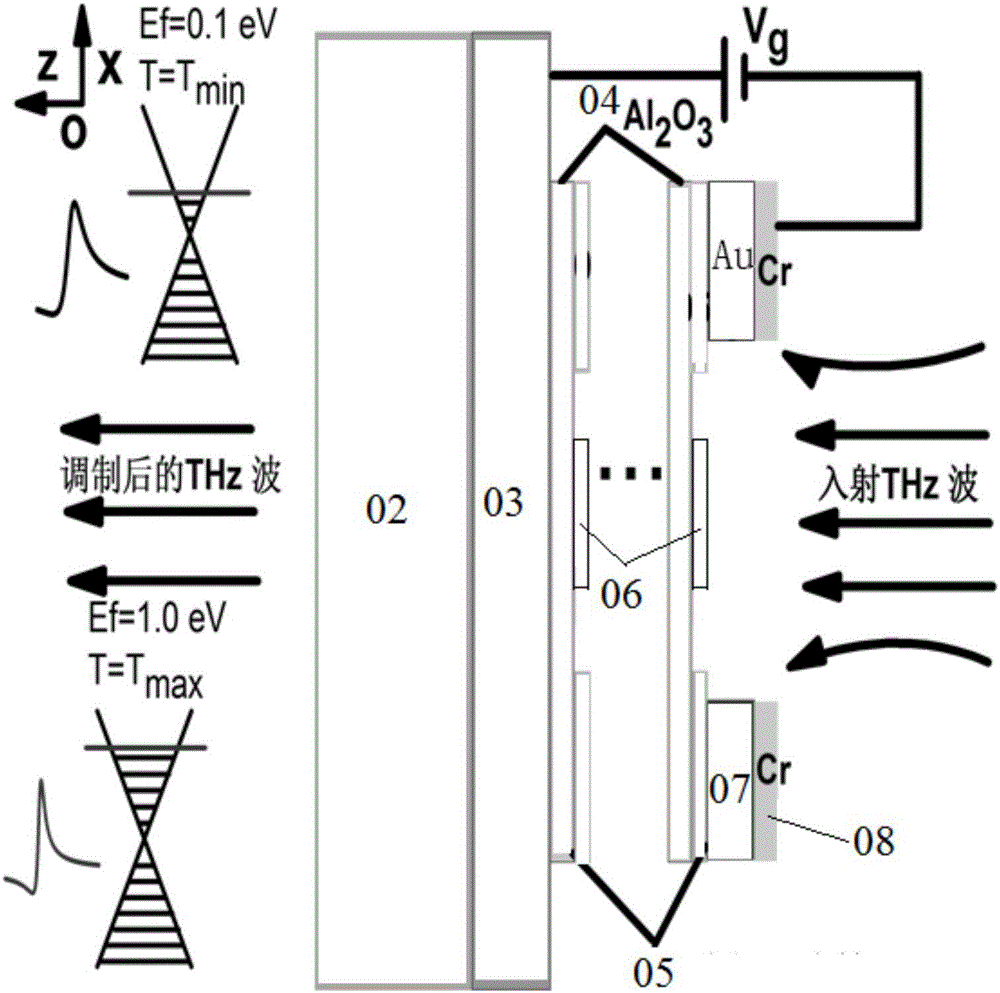

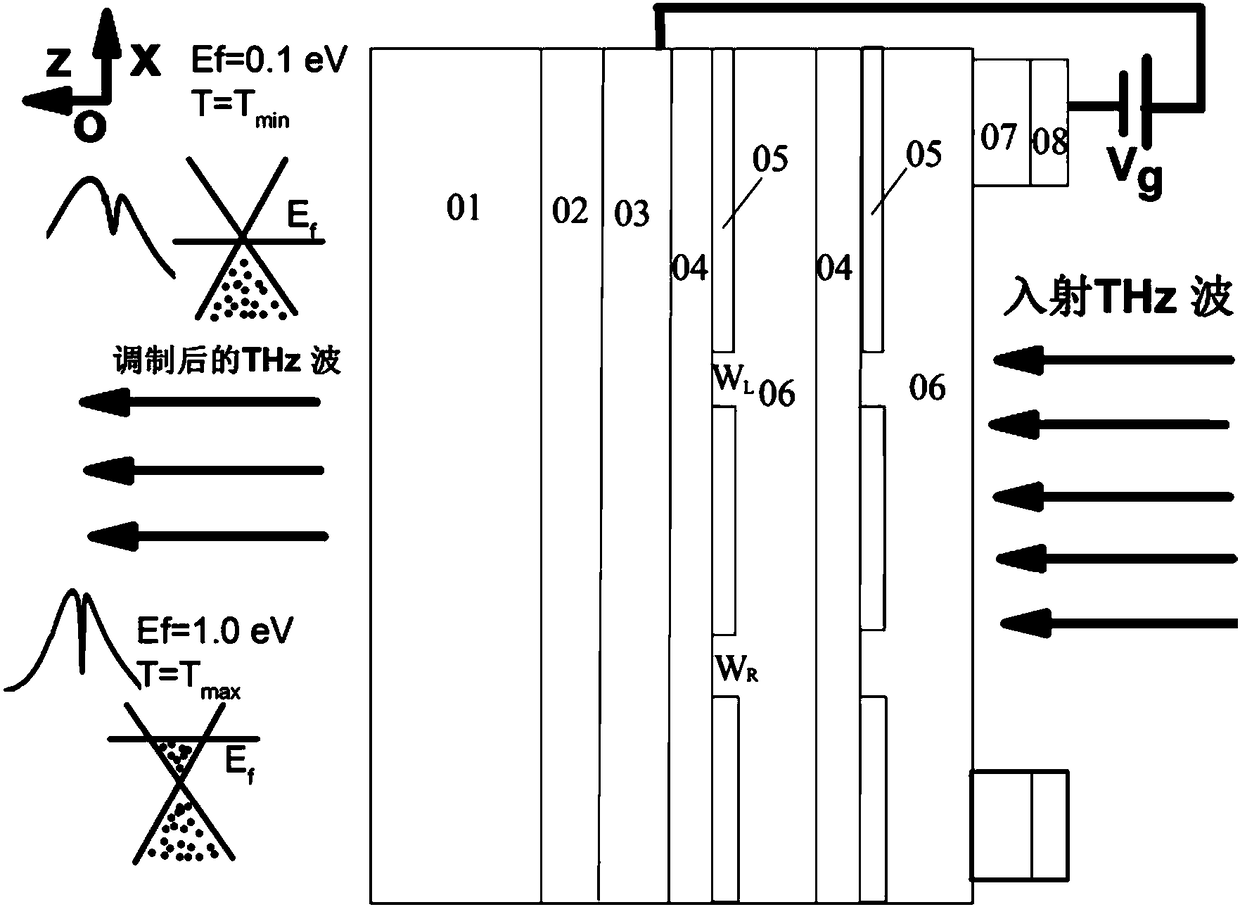

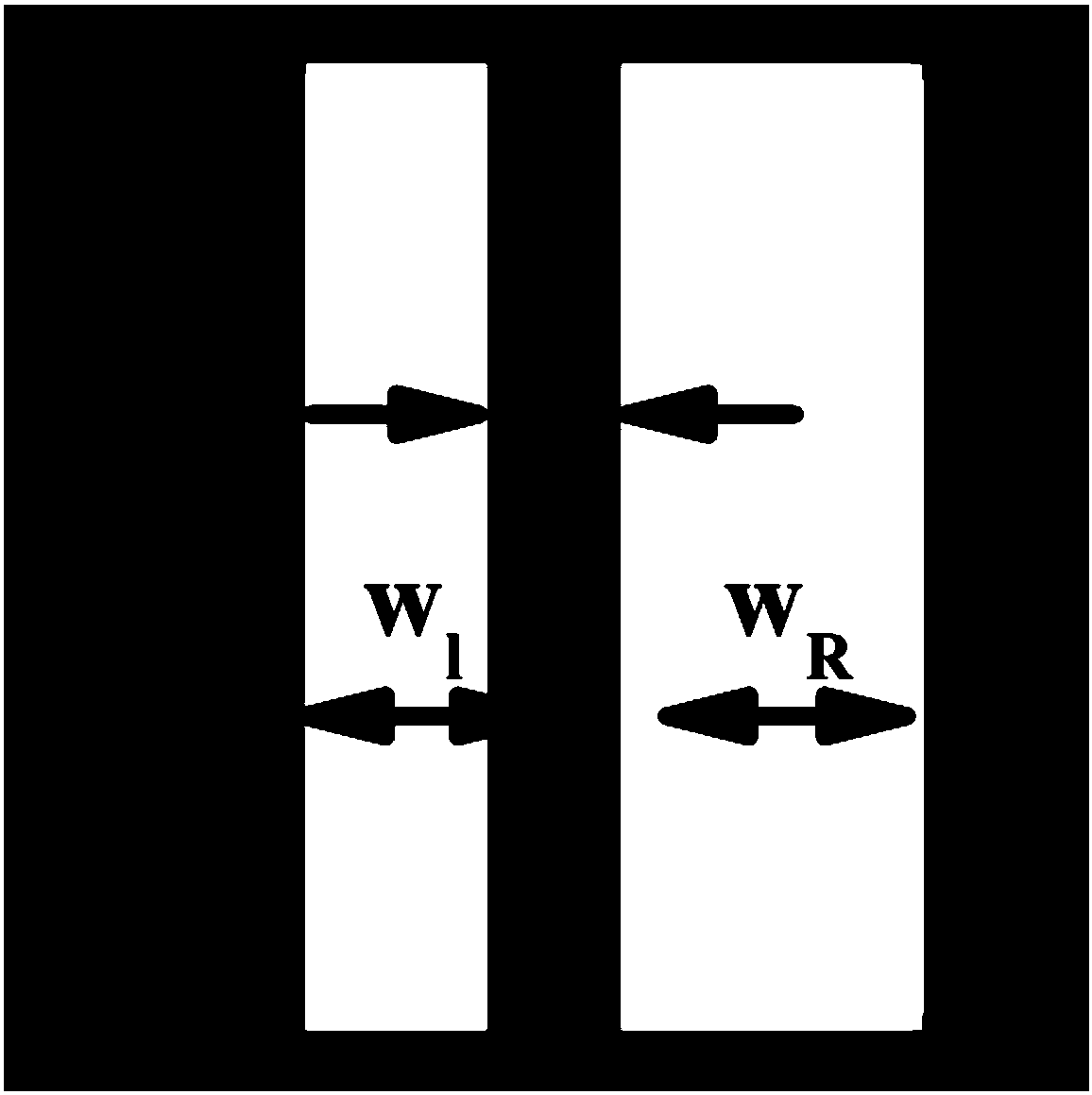

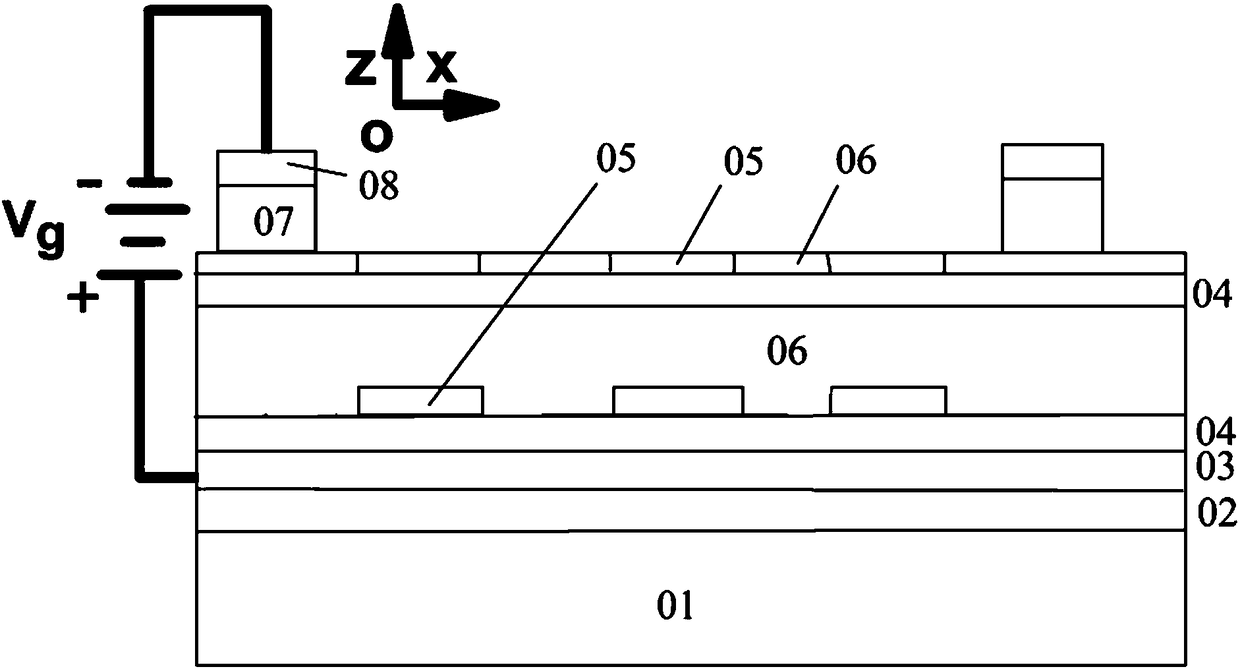

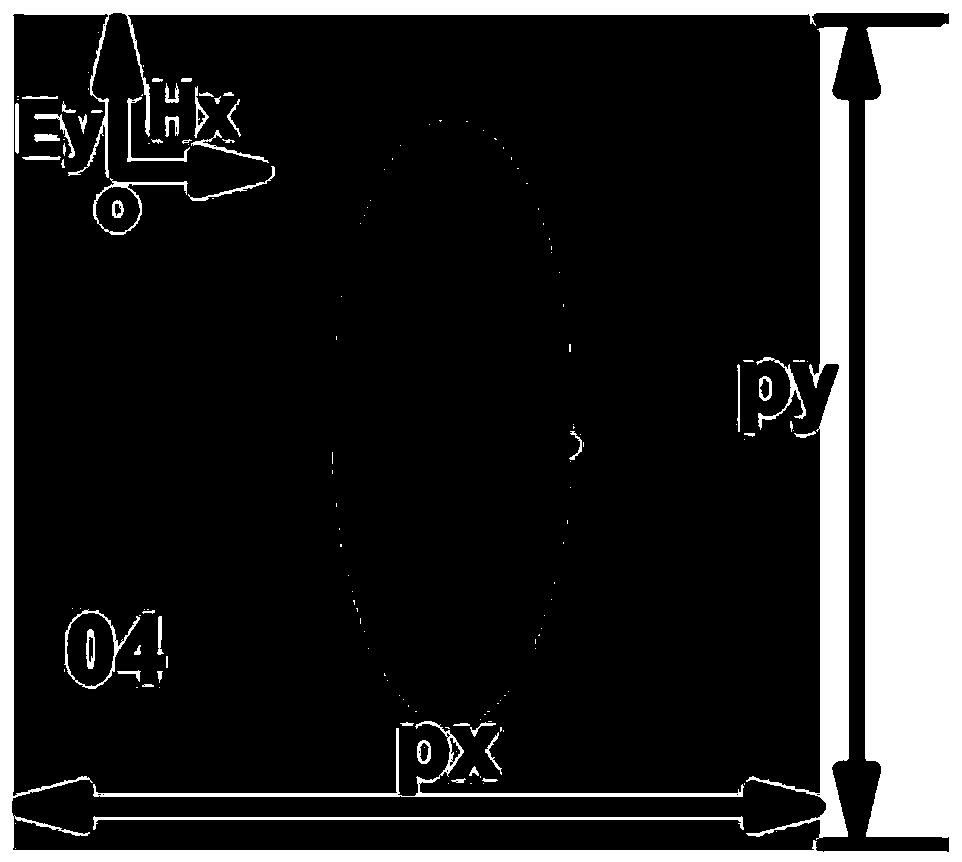

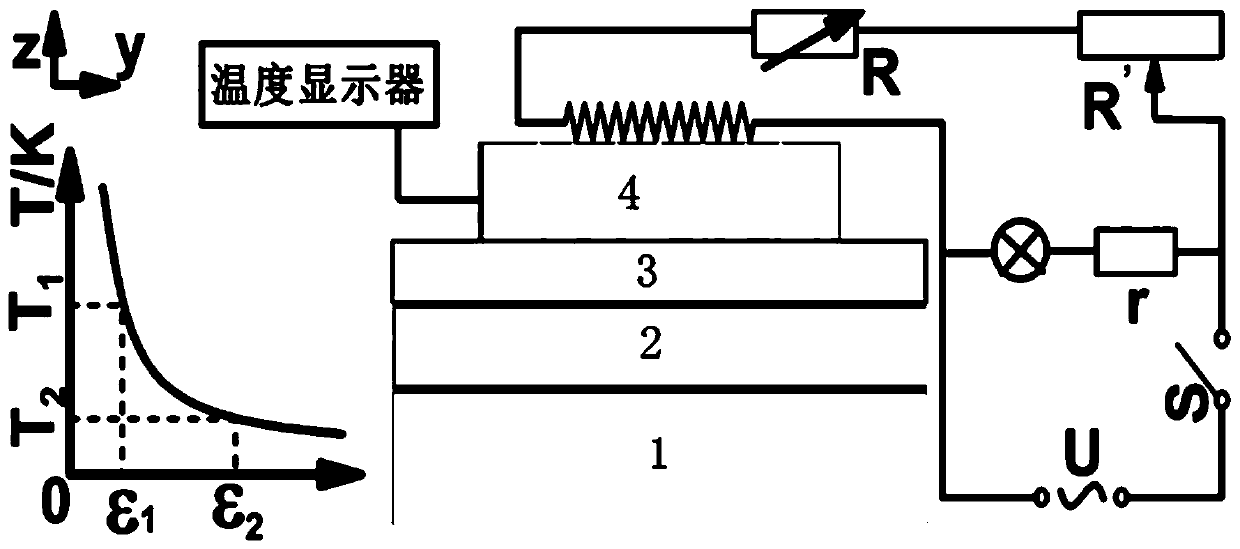

THz modulator based on graphene-metal composite microstructure and preparation thereof

ActiveCN106449381AChanging the Fermi levelGreat modulation depthSemiconductor/solid-state device manufacturingNon-linear opticsMetal microstructureCvd graphene

The invention relates to a THz modulator based on graphene-metal composite microstructure and preparation thereof. The THz modulator includes: a polymer flexible substrate layer; a doped semi-conductor epitaxial layer; a A1203 insulating-active region structure composite layer which grows on the doped semiconductor epitaxial layer and is composed by superposing at least one A1203 insulating-active region sub-structure which includes an A1203 insulating layer which is disposed therebelow and a graphene microstructure layer and a metal microstructure layer which grow on the A1203 insulating layer, the metal microstructure layer being disposed inside the graphene microstructure layer and is arranged spaced from the graphene microstructure layer to form the active sub-region structure of the THz; a metal layer which is vapor plated on one active sub-structure in the uppermost and processed to form a metal top electrode. Compared with prior art, according to the invention, the THz modulator can effectively regulate THz waves, has high quality factor, excellent adjustability and great modulation depth, etc.

Owner:SHANGHAI NORMAL UNIVERSITY

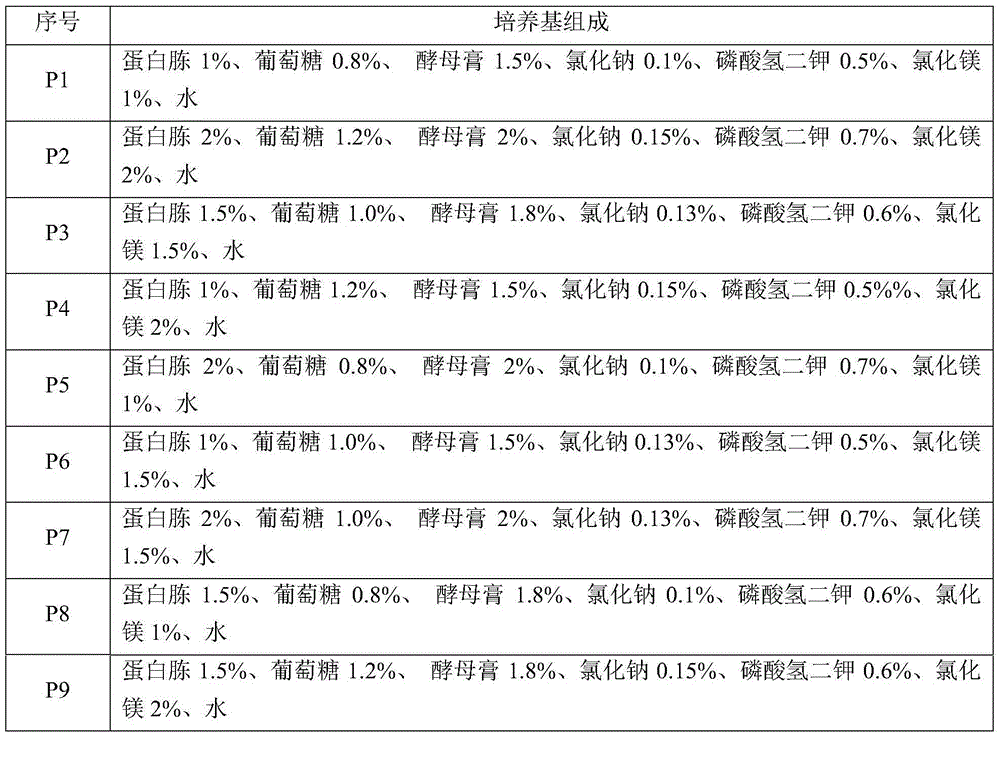

Degradation bacterium for oil-base drilling cuttings, and preparation method and application method thereof

ActiveCN104312936AIncreased degradation rateShort degradation cycleBacteriaWater contaminantsBioremediationKocuria kristinae

The invention discloses a degradation bacterium for oil-base drilling cuttings, and a preparation method and an application method thereof, and belongs to the technical field of microbiological processing of oil-containing solid wastes. The degradation bacterium for oil-base drilling cuttings is composed of multiple microorganisms, and is prepared by performing fermentation culturing on three degradation single bacteria which are obtained by performing enriching, separation, purification and screening on bacteria in petroleum polluted soil. The degradation bacterium for oil-base drilling cuttings comprises pPseudomonas aeruginosa, kocuria kristinae and acinetobacter calcoaceticus, is used for degradation of petroleum composition in oil-base drilling cuttings, and has the substantial advantages of high oil removal efficiency and short processing period. When oil-base drilling cutting with the initial oil content less than 5% is processed by using the degradation bacterium for 5-30 d, the oil content can be reduced to 1% or less, and the oil removal rate can reach 80% or more. The degradation bacterium also has good application prospect when being applied to biological restoration of oil-containing soil and oil-containing sludge.

Owner:CHINA PETROCHEMICAL CORP +1

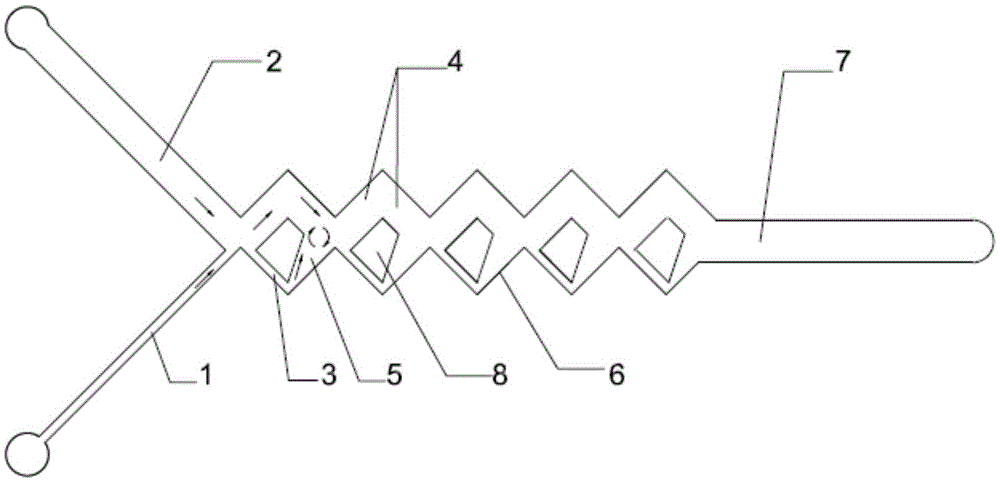

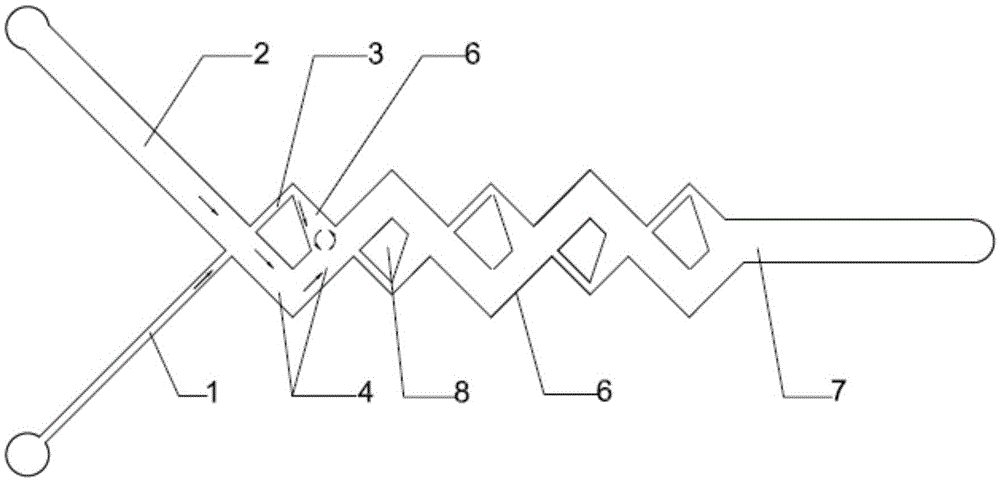

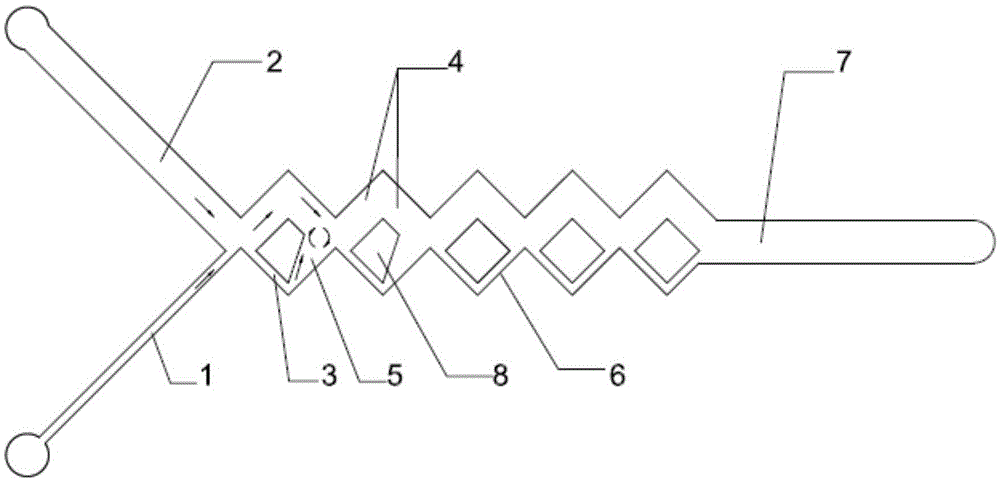

Planar passive micromixer

ActiveCN105664773ASave spaceSimple structureTransportation and packagingMixersEngineeringMixing effect

The invention discloses a planar passive micromixer.The planar passive micromixer comprises an inlet passage, an outlet passage and at least one mixing unit between the inlet passage and the outlet passage.Each mixing unit comprises a first flow distribution passage, a second flow distribution passage and a flow mixing cavity, wherein the first flow distribution passage and the second flow distribution passage are used for liquid flow distribution, the flow mixing cavity is used for mixing liquid flowing from the first flow distribution passage and the second flow distribution passage and communicated with the first flow distribution passage and the second flow distribution passage of the adjacent mixing unit or communicated with the outlet passage.According to Coada effects, the micromixer structurally leads a medium to form chaotic convection in a convection cavity, and mixing effects are remarkably improved.

Owner:SUZHOU WENHAO MICROFLUIDIC TECH CO LTD

High-dielectric-coefficient polyimide thin film

The invention discloses a high-dielectric-coefficient polyimide thin film and a preparation method thereof. Polyimide obtained through polycondensation of dicarboxylic anhydride monomers and diamine monomers serves as a base body and is doped with, by weight, 1-3% of fullerene, 0-3% of lasurite powder and 0-3% of nanometer montmorillonite. The polyimide thin film has a high dielectric constant of 12 to 18 and is an excellent material for manufacturing a capacitor, the mechanical strength and all physical indexes of the polyimide thin film are the same as those of an ordinary polyimide thin film, high temperature resistance, high strength and high stability are kept, and the advantage of excellent flexibility is achieved; the polyimide thin film is durable in use, keeps the high dielectric constant for a long time, and is simple in preparation method and suitable for large-scale production and application.

Owner:JIANGSU YABAO INSULATION MATERIAL

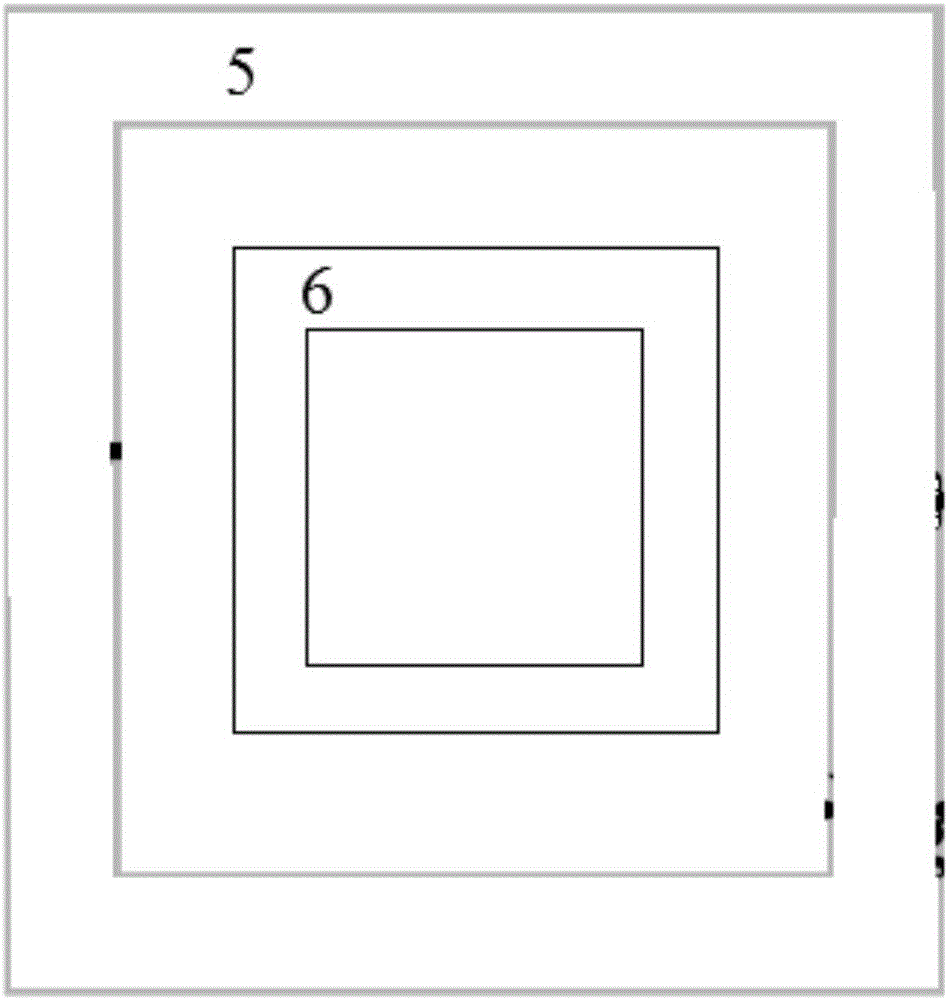

Graphene-based complementary type asymmetric n-type structure THz modulator and manufacture method therefor

ActiveCN108539423AChanging the Fermi levelAdjust the waveformNon-linear opticsAntennasSputteringInsulation layer

The invention relates to a graphene-based complementary type asymmetric n-type structure THz modulator and a manufacture method therefor. The THz modulator comprises a polymer flexible substrate layer, an indium tin oxide (ITO) semiconductor sputtering layer and an Al2o3 insulation-graphene active region structure composite layer, wherein the Al2o3 insulation-graphene active region structure composite layer is grown on an ITO layer and is formed by superposing at least one Al2o3 insulation-active region substructure, the Al2o3 insulation-active region substructure comprises an Al2o3 insulationlayer positioned on a lower part and a complementary type graphene microstructure layer grown on the Al2o3 insulation layer, and an electric conduction gel-gel layer is made as an upper electrode positioned on an uppermost active region substructure. Compared with technologies of the prior art, the modulator and the method disclosed in the invention are advantageous in that terahertz waves can beeffectively adjusted; the modulator are high in quality factors (Q)30), great in adjustable performance, and large in modulation depth and the like.

Owner:SHANGHAI NORMAL UNIVERSITY

Method for extracting proanthocyanidin from banana peels

The invention discloses a method for extracting proanthocyanidin from banana peels. The method comprises the following steps of: banana peel extraction; color protection; quick freezing; smashing; microwave drying; ionic liquid extraction; ultracentrifugation; and spray drying to obtain a finished product of the proanthocyanidin. By utilizing quick freezing and low-temperature smashing technologies, the banana peels can be smashed uniformly and are small in particle size, low in proanthocyanidin loss and high in drying speed, and a sterilizing effect can also be realized while the banana peels are dried and dehydrated; the proanthocyanidin is prevented from being damaged by using a microwave-assisted ionic liquid extracting method; and the ionic liquid is easy to recycle. The method is simple in operation, mild in condition, high in yield and efficiency, clean and harmless in production process, low in energy consumption, high in benefit, high in yield and purity of the proanthocyanidin, suitable for large-scale production and application, and wide in prospects for comprehensive utilization of the banana peels and the commercialized market development of natural proanthocyanidin.

Owner:杨公明

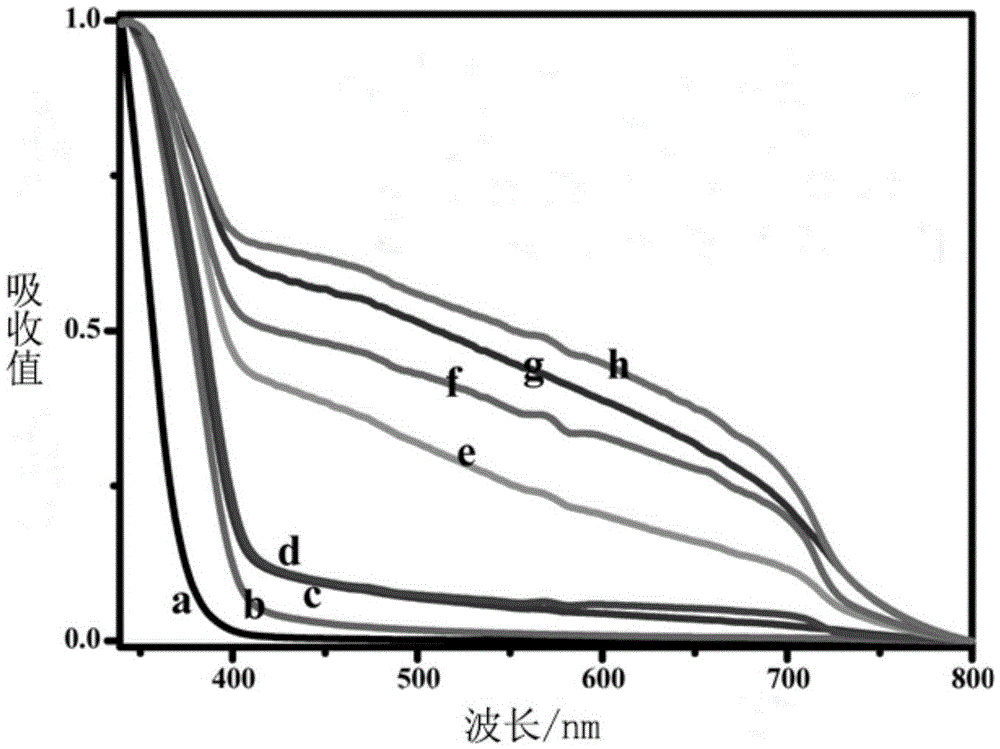

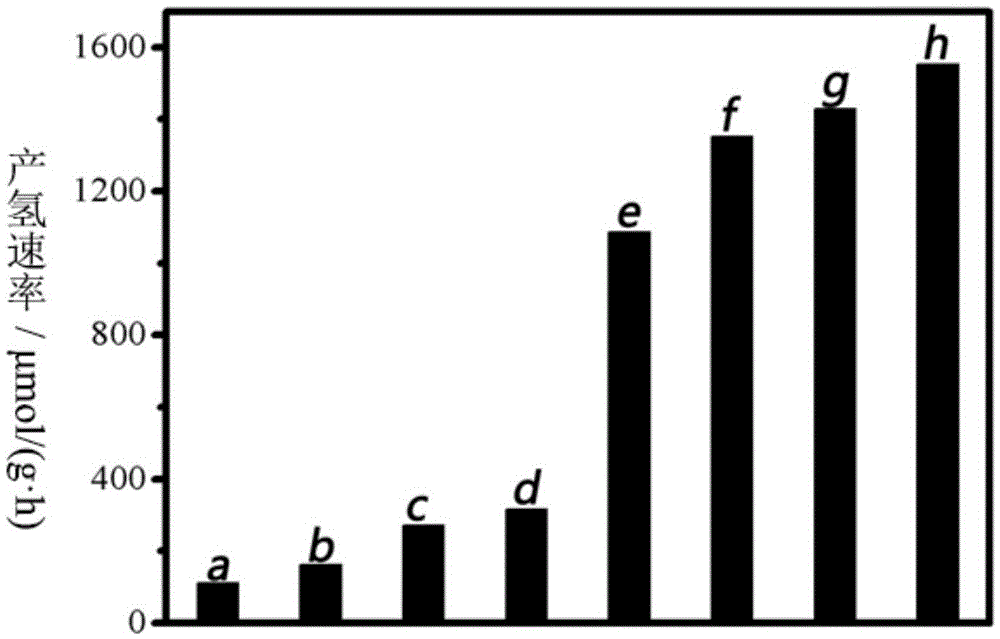

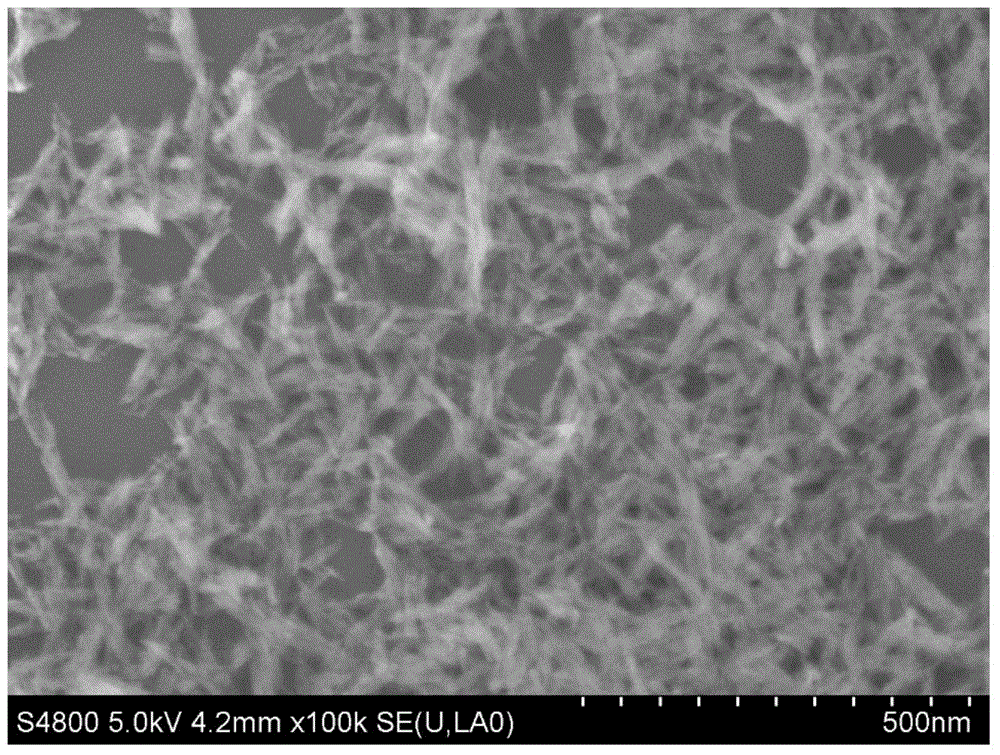

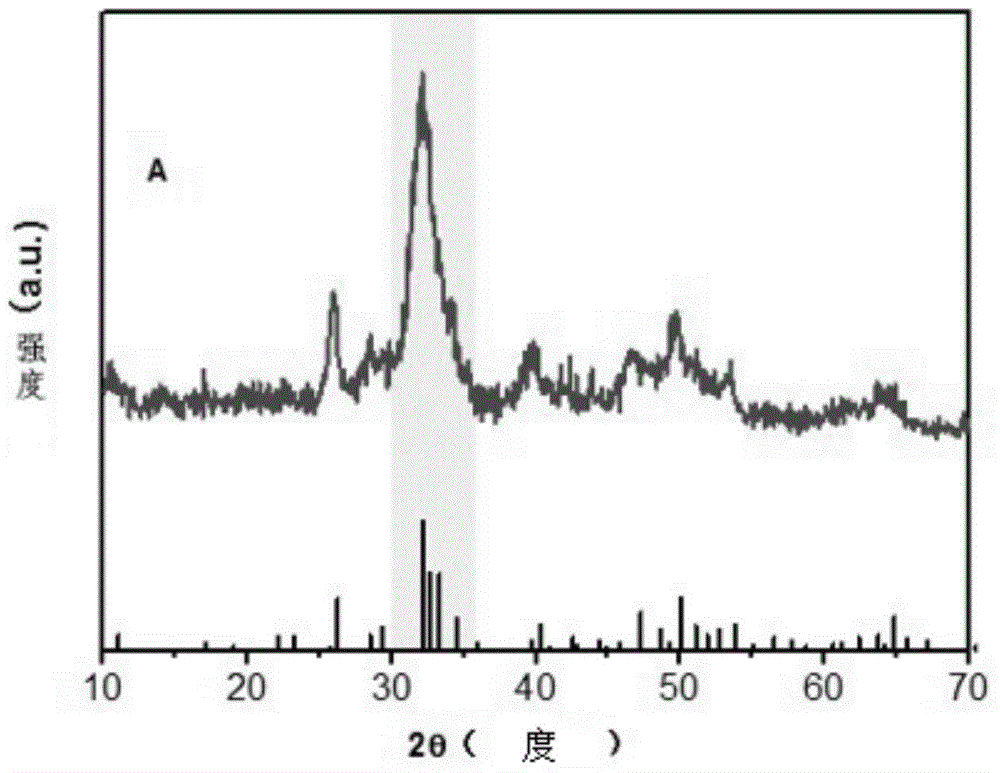

Carbon-modified TiO2/WO3 composite nanofiber photocatalyst, preparation method and application

ActiveCN105664922AImprove photocatalytic performancePromote orderMetal/metal-oxides/metal-hydroxide catalystsFiberCarbon layer

The invention discloses a carbon-modified TiO2 / WO3 composite nanofiber photocatalyst, a preparation method and application and belongs to the technical field of nano photocatalytic materials. The preparation method includes following steps: 1), adding polyvinyl pyrrolidone, ammonium tungstate and tetrabutyl titanate into mixed liquid of alcohol and acetic acid, and mixing well before electrostatic spinning to obtain nanofiber felt; 2), calcining the nanofiber felt to obtain TiO2 / WO3 nanofiber; 3), adding the TiO / WO3 nanofiber, glucose and water into a reaction kettle, allowing hydrothermal reaction, filtering, cleaning, and drying to obtain the photocatalyst. The TiO2 / WO3 composite nanofiber is modified through carbon, a carbon layer on the surface of TiO2 is used as an electron collector, and WO3 is used as an electron hole collector, so that photo-generated carriers can be separated effectively and photocatalytic performance of the photocatalyst can be improved. In addition, WO3 can promote ordering and graphitizing of the carbon layer, so that photocatalytic performance of the photocatalyst can be further improved.

Owner:ZHENGZHOU UNIV

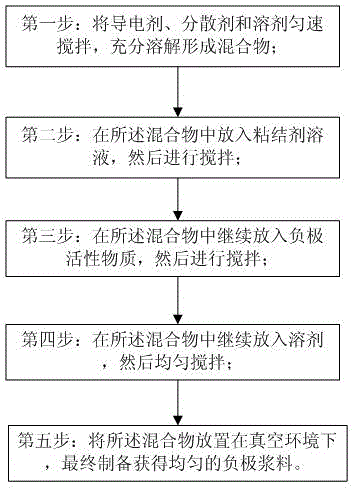

Method for preparing negative pole slurry for lithium ion batteries

The invention discloses a method for preparing negative pole slurry for lithium ion batteries, which comprises the following steps of: 1, stirring a conductive agent, a dispersing agent and a solvent at a constant speed, so that a mixture is formed after the conductive agent, the dispersing agent and the solvent are completely dissolved; 2, adding a binder solution into the mixture, and then stirring the obtained object; 3, continuing to add a negative active material into the mixture, and then stirring the obtained object; 4, continuing to add a solvent into the mixture, and then uniformly stirring the obtained object; and 5, placing the mixture in a vacuum environment so as to finally obtain uniform negative pole slurry. According to the method for preparing negative pole slurry for lithium ion batteries, disclosed by the invention, the working efficiency of preparing the negative pole slurry for lithium ion batteries can be obviously improved, and the uniformity and stability of the negative pole slurry can be guaranteed; and meanwhile, the reduction of the production cost is facilitated, and the performance of lithium ion batteries is improved finally, therefore, the method is suitable for large-scale production applications and facilitates the improvement of the market application prospects of products of battery manufacturers.

Owner:TIANJIN LISHEN BATTERY

Sodium alginate-hydroxyapatite hybridization nano particle and preparing method thereof

InactiveCN104958766ADifferent structureDifferent shapesOrganic active ingredientsPharmaceutical non-active ingredientsApatiteCalcium EDTA

The invention relates to a sodium alginate-hydroxyapatite hybridization nano particle. The sodium alginate-hydroxyapatite hybridization nano particle comprises, by mass, 65%-99.5% of hydroxyapatite and 0.5%-35% of sodium alginate, the sodium alginate-hydroxyapatite hybridization nano particle is in a needle shape, the length of the needle ranges from 10 nm to 70 nm, and the width of the needle ranges from 3 nm to 20 nm. A preparing method includes the steps that alginic acid polysaccharide is dissolved into deionized water to obtain an alginic acid polysaccharide solution with the mass concentration ranging from 0.2% to 0.8%, a calcium salt aqueous solution and a phosphate aqueous solution are added into alginic acid polysaccharide solution under stirring, and the adding amount of the calcium salt aqueous solution and the phosphate aqueous solution is determined with the molar ratio of Ca / P in a reaction system being (1-2.0):1 as a limit; and in addition, the volume ratio of the calcium salt aqueous solution to the phosphate aqueous solution is 1:(20-40), then the pH value of the reaction system is adjusted to be 10-12, stirring is stopped, standing ageing is carried out for at least 5 days, and a reaction product is collected after standing ageing is carried out and is dried. The sodium alginate-hydroxyapatite hybridization nano particle is particularly suitable for serving as an anti-cancer drug carrier.

Owner:SICHUAN UNIV

Special spherical calcium carbonate for stone paper and preparation method of special spherical calcium carbonate

ActiveCN104558687AImprove processing fluidityGood dispersionCalcium/strontium/barium carbonatesPlasticulturePhysical chemistry

The invention discloses special spherical calcium carbonate for stone paper and a preparation method of the special spherical calcium carbonate and provides spherical calcium carbonate which has the good liquidity in a heated state. The spherical calcium carbonate is formed by polymerizing caprolactam after the caprolactam infiltrates into micro-pores in the spherical calcium carbonate surface. A liquid infiltrates into the spherical tiny calcium carbonate surface under the action of high-pressure push of a high-pressure expansion fluid device, and energy accumulated on the spherical tiny calcium carbonate surface is released and expanded quickly due to sudden pressure release, so that the micro-pores are formed in the calcium carbonate surface, and spherical heavy calcium carbonate of the micro-pores in the surface adsorbs the caprolactam and is polymerized to form the spherical calcium carbonate with a caprolactam polymer inlaid in the surface. When the spherical calcium carbonate is used for processing raw materials of the stone paper, the processing fluidity and the dispersity of the stone paper are substantially improved due to the spherical characteristic of the calcium carbonate and the easy-plasticizing characteristic of the caprolactam polymer, and the good processing fluidity of the stone paper can be realized under the condition that a lubrication additive is reduced or not used.

Owner:JIANGSU XIYI HIGH NEW DISTRICT TECH DEV CO LTD

Mineral fiber softening agent

InactiveCN105155267AStrong Penetrating AdhesionImprove bindingInorganic fibres/flakesFibre treatmentAdhesivePlant fibre

The invention discloses a mineral fiber softening agent. The mineral fiber softening agent is prepared from the following raw materials in part by weight: 40-55 parts of vinyl acetate-ethylene copolymer emulsion, 15-25 parts of vital gluten, 5-15 parts of inorganic adhesives, 3-5 parts of chlorinated polyethylene emulsion, 0.5-2 parts of organic adhesives and 0.2-0.5 part of silane unsaturated monomer. The vital gluten, the inorganic adhesives and the organic adhesives are subjected to compound modification in an acylation manner, by a strong polarity polar group of the chlorinated polyethylene emulsion, the obtained softening agent has high-permeation adhesion on mineral fibers, permeates in the fibers and firmly wraps surfaces of the mineral fibers, and owing to viscoelasticity of the vital gluten, the mineral fibers have good flexibility. Because the softening agent contains the water-soluble inorganic adhesives, metal cation electrolytes are formed on surfaces of the mineral fibers when the mineral fibers are softened by the softening agent, potential difference is generated between the surfaces of the mineral fibers and surrounding liquid, particularly, a binding force of the mineral fibers and plant fibers is increased, when the plant fibers are replaced, the mineral fibers can be connected with the plant fibers, ionic bonds are formed by combination of ions, and bonding strength of the fibers is improved.

Owner:广州市朗尔化工助剂有限公司

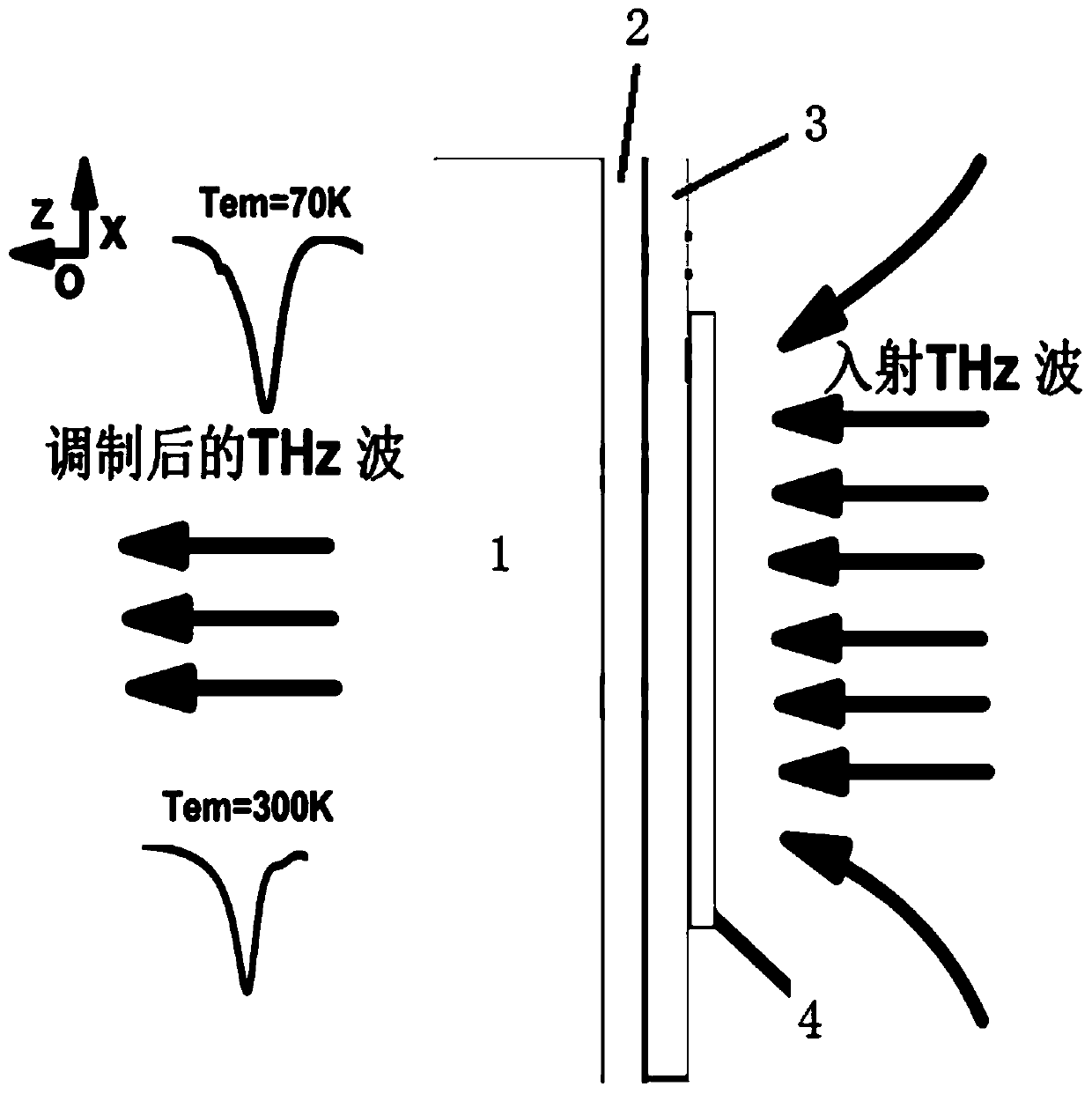

Terahertz wave modulator based on strontium titanate all-dielectric metamaterial and preparation method of terahertz wave modulator

ActiveCN110320678AChange waveformGreat modulation depthNon-linear opticsMicro structureStrontium titanium oxide

The invention relates to a terahertz wave modulator based on a strontium titanate all-dielectric metamaterial and a preparation method of the terahertz wave modulator. The terahertz wave modulator comprises a polymer flexible substrate layer, a doped semiconductor epitaxial layer and a SiO2 insulation-strontium titanate micro-structure composite layer, wherein the doped semiconductor epitaxial layer grows on the surface of the polymer flexible substrate layer; the SiO2 insulation-strontium titanate micro-structure composite layer grows on the semiconductor silicon epitaxial layer and comprisesa lower SiO2 insulating layer and a strontium titanate micro-structure layer growing on the SiO2 insulating layer. Compared with the prior art, the prepared modulator has the advantages that the quality factor is high, the adjustability is good, the modulation depth is large, the preparation process is relatively simple, and the modulator is suitable for large-scale production and application.

Owner:SHANGHAI NORMAL UNIVERSITY

Thermoplastic starch elastomer and preparation method thereof

The invention provides a thermoplastic starch elastomer. An elastic polymer of a starch-polybutadiene-vital gluten interpenetrating polymer network is formed by hydroxyl-terminated polybutadiene and low-molecular-weight straight-chain starch and vital gluten chain expansion, and the polymer is a high-strength thermoplastic starch elastomer with large intensity and excellent heat-resistance performance. The invention further provides a preparation method of the thermoplastic starch elastomer. The branched structure of starch milk is disassembled through a high-pressure homogenizer, a starch chain is fractured and converted into a straight chain structure, the molecular weight of starch is reduced and distributed in a narrow constant range, then chain expansion is performed on starch milk together with hydroxyl-terminated polybutadiene and vital gluten, so that the polymerization is increased, the molecular weight is improved, not only can the intensity be high, but also the processing temperature window is broadened. The preparation method is simplified in production technology, the production environment is clean, the performances of products are improved, and the preparation method is suitable for large-scale production and application.

Owner:东莞市汇泽实业有限公司

Method for removing endotoxin in protein

InactiveCN105001299AEfficient removalEasy to operatePeptide preparation methodsUltrafiltrationFiltration

The invention provides a method for removing endotoxin in protein. The method adopts a sequential combination of chromatography, ultrafiltration and common filtration, and accords with a protein purification process flow. With the method, protein purification is realized while endotoxin is effectively removed, and the properties of protein is not influenced. The method is especially suitable to be used in treating various genetically engineered bacteria expressed intracellular and extracellular proteins. With optimized designs of the conditions of filtering mode, filtering pressure, membrane pore size and the like, operation steps and operation time are simplified, such that production cost is reduced, and processing capacity is improved. With the method provided by the invention, the endotoxin content can be reduced to an animal clinical application standard range, and the properties of the product is not influenced while the endotoxin is removed. The method is suitable for large-scale productions and applications.

Owner:TIANJIN RINGPU BIO TECH

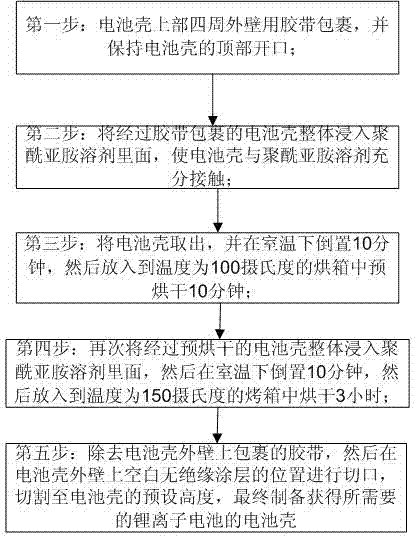

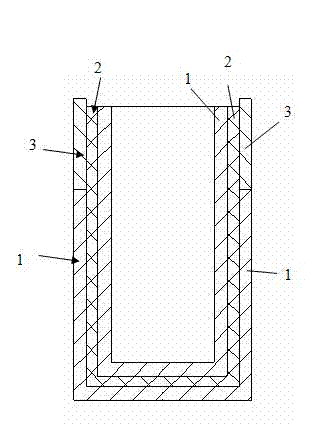

Preparation method for insulating coating of lithium ion battery case and lithium ion battery

InactiveCN103050731AImprove safety performanceExtended service lifeSecondary cellsCell component detailsChemistryLithium electrode

The invention discloses a lithium ion battery, which comprises a battery case (2), wherein an insulation coating (1) is coated on the battery case (2). The invention further discloses a preparation method for the insulating coating of a lithium ion battery case. The preparation method for the insulating coating of the lithium ion battery case and the lithium ion battery, disclosed by the invention, can remarkably improve the safety performance of the lithium ion battery and prolong the service life of the lithium ion battery, and the preparation method is suitable for large-scale production and application, and is good for improving the market application prospect of the products of a manufacturer, so that the preparation method has great significance on production and practice.

Owner:TIANJIN LISHEN BATTERY

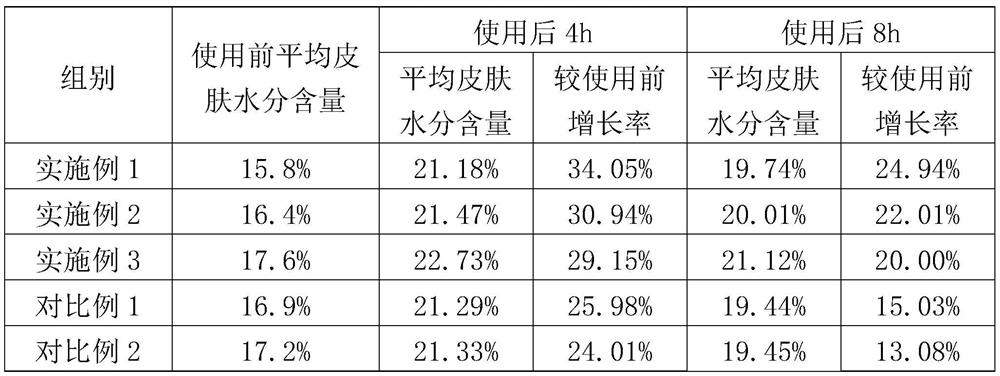

Moisturizing mask containing Qinghai salt lake black mud extract and preparation method thereof

InactiveCN112206186AIncrease elasticityIncrease brightnessCosmetic preparationsToilet preparationsArginineOpuntia dillenii

The invention relates to a moisturizing mask containing Qinghai salt lake black mud extract and a preparation method thereof. The moisturizing mask containing Qinghai salt lake black mud extract comprises the following raw materials: water, a thickener, a humectant, a sodium hyaluronate cross-linked polymer, acetylated sodium hyaluronate, citrus peel extract, evening primrose root extract, desertsand verbena leaf extract, agave stem extract, yucca brachycarpa root extract, opuntia dillenii flower extract, Indian damnacanthus stem extract, arachnoid extract, sludge extract, dendrobium stem extract, piper kawaii leaf / root / stem extract, arginine, oat beta-glucan, oligopeptide-1, p-hydroxyacetophenone and glycerol caprylate. The moisturizing mask containing Qinghai salt lake black mud extractcan densely moisturize the skin, make the skin moist and soft, clean the skin, promote the generation of skin collagen, make the skin compact and glossy, and effectively improve fine lines, loosenessand dullness.

Owner:青海湖宝生物科技有限公司

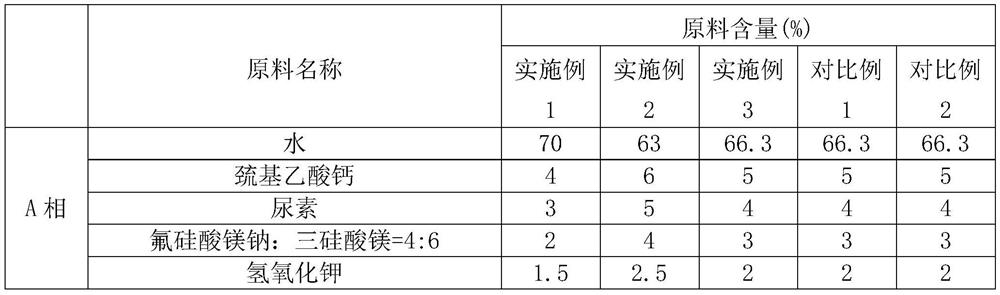

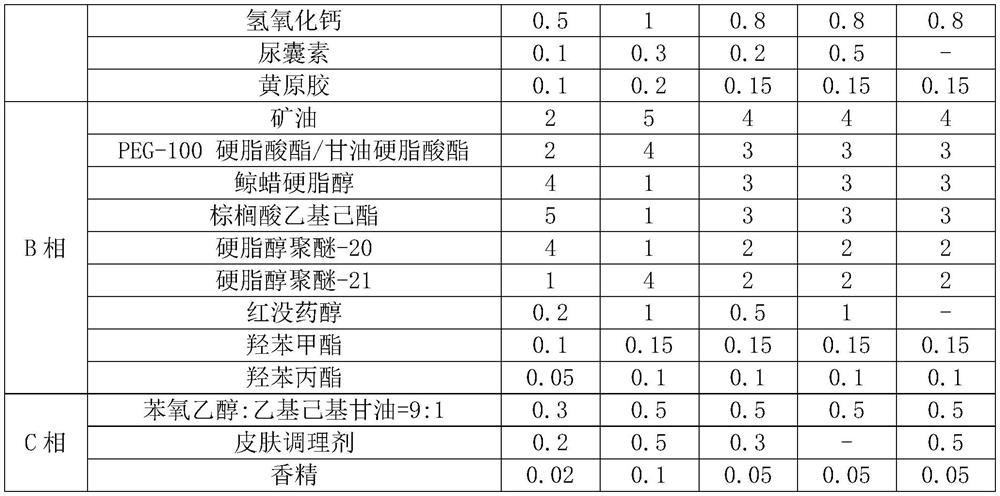

Depilatory paste and preparation method thereof

PendingCN112006958AReduce inflammationInflammation, relieve skin acne relieveCosmetic preparationsHair removalBiotechnologyPolygonum cuspidatum root extract

The invention relates to a depilatory paste and a preparation method thereof. Raw material components of the depilatory paste comprise: 63 to 70 parts by weight of water; 3-5 parts by weight of a humectant; 6-7 parts by weight of an emollient; 0.1 to 0.2 part by weight of a water-soluble thickening agent; 1 to 4 parts of oil-soluble thickener, 2 to 4 parts of emulsion stabilizer, 7 to 9 parts of emulsifier, 2 to 3.5 parts of pH regulator, 0.2 to 1 part of bisabolol, 0.1 to 0.3 part of allantoin, 0.2 to 0.5 part of skin conditioner and 4 to 6 parts of chemical depilatory, wherein the skin conditioner is a mixture of butanediol, water, a centella asiatica extract, a polygonum cuspidatum root extract, a scutellaria baicalensis root extract, a tea leaf extract, a glycyrrhiza glabra root extract, a chamomile extract and a rosemary leaf extract. The depilatory paste provided by the invention has excellent depilatory effect and use comfort, is suitable for a wide range of people, and is suitable for large-scale production and application.

Owner:广州市逸轩精细化工有限公司

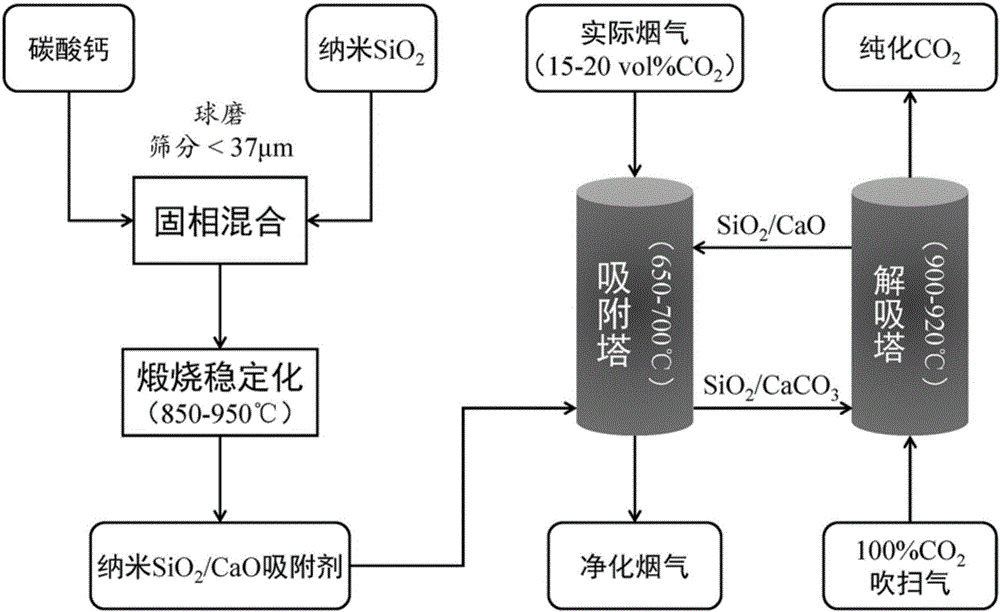

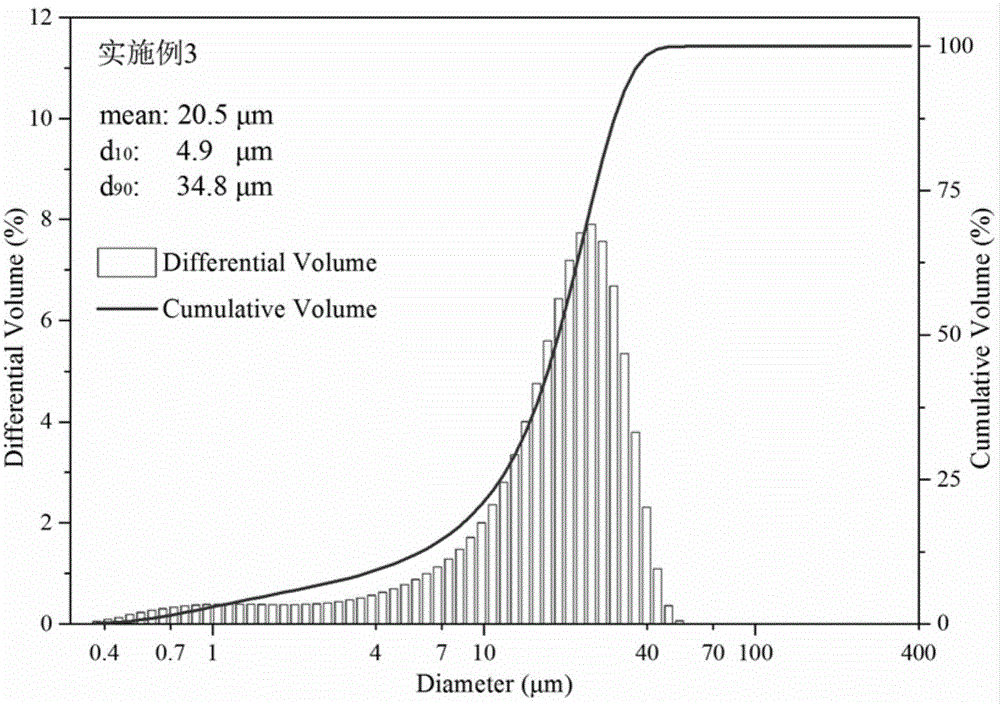

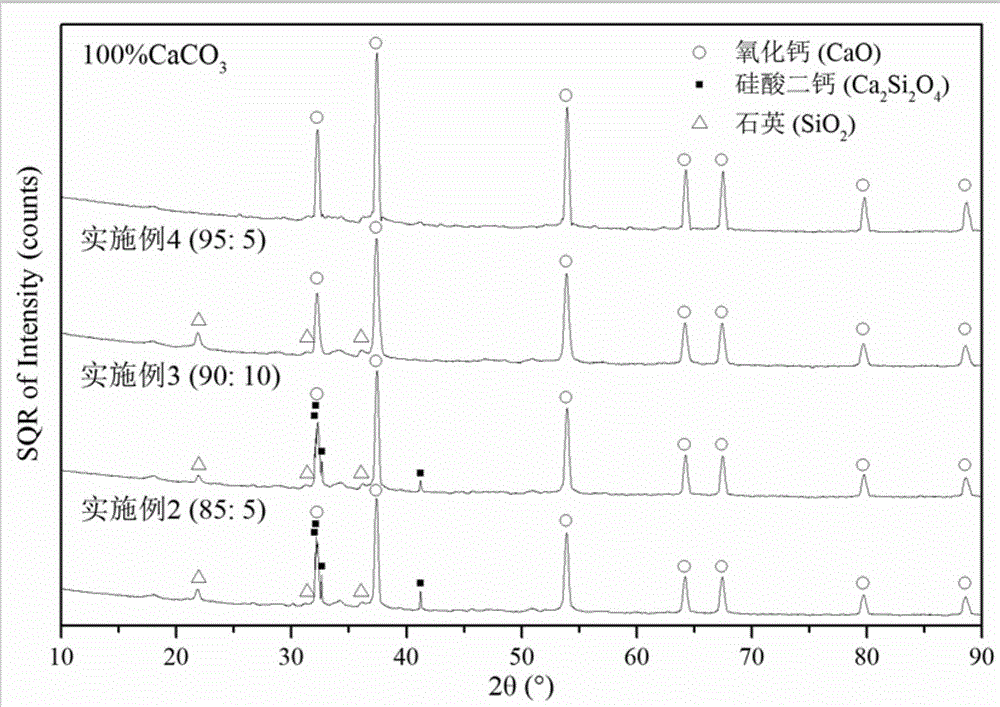

Synthesis method and application of nanometer SiO2/CaO adsorbent

InactiveCN106475041AHigh energy consumptionIncrease costGas treatmentOther chemical processesMolecular sieveFluid phase

The invention relates to a synthesis method of a nanometer SiO2 / CaO adsorbent. Calcium carbonate and nanometer SiO2 are subjected to ball mining, crushing and sieving; the specific surface area of the nanometer SiO2 is greater than 200m<2> / g, and the nanometer SiO2 includes but is not limited to precipitation method nanometer SiO2, vapor phase method nanometer SiO2, ZSM-5 molecular sieves, MCM-41 molecular sieves, MCM-48 molecular sieves, MCM-50 molecular sieves and SBA-15 molecular sieves; the calcium carbonate (through being metered by CaO mass) and the nanometer SiO2 are weighed and are subjected to solid phase mixing according to a mass ratio of (80:20) to (95:5); the mixture is calcined for 2 to 6h at 850 to 950 DEG C in inert gas atmosphere; after cooling, an adsorbent product is obtained; when the adsorbent product is used for a circulating fluidized bed, the fast CO2 gathering and the adsorbent regeneration can be realized. The method has the advantages that a solid phase mixing technology is used; a liquid phase reaction process with high energy consumption and high cost is avoided; the product adsorption speed is high; the adsorption quantity proportion can reach 85 percent or higher at a 20s fast adsorption stage; the high-temperature stability is high; the circulation adsorption capacity is great; the adsorption capacity can still reach 0.30g CO2 / g of the adsorbent after 30 circulations; the method is suitable for the realization of mass application in the circulating fluidized bed.

Owner:TSINGHUA UNIV

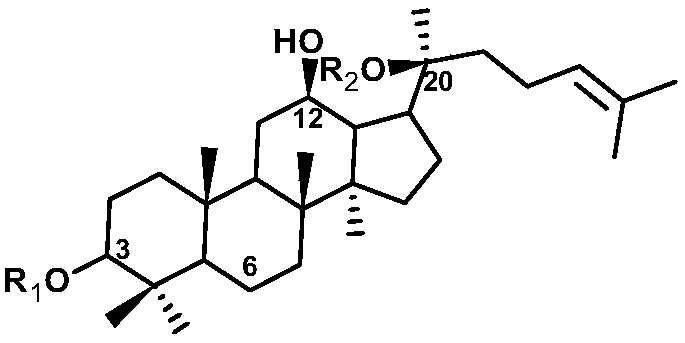

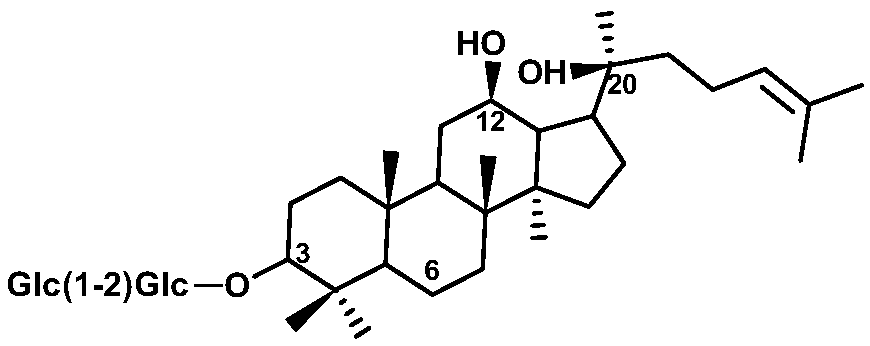

Biotransformation method of rare ginsenoside Rg3

ActiveCN109182439AImprove conversion efficiencySuitable for large-scale production applicationsFermentationAlgluceraseDrug biotransformation

The invention discloses a biotransformation method of rare ginsenoside Rg3, comprising the steps: (1) extracting ginseng to obtain total ginsenoside extract; (2) adding any one or more of Beta-Glucosidase BglPm, a-L-Arabinofuranase Abf22-3, Beta-Glucosidase Bgp1 or a-L-arabinopyranosidase Bgp2 in the total ginsenoside extract for carrying out biotransformation to obtain a transformation product containing rare ginsenoside Rg3. The invention adds any one or more enzymes of Beta-Glucosidase, a-L-Arabinofuranase, Beta-Glucosidase or a-L-arabinopyranosidase in the total ginsenoside extract for biotransformation, and the biotransformation efficiency of the rare ginsenoside Rg3 is remarkably improved. The biotransformation method of the invention is environmentally friendly, has high conversionefficiency and is suitable for large-scale production and application.

Owner:NORTHEAST FORESTRY UNIVERSITY +1

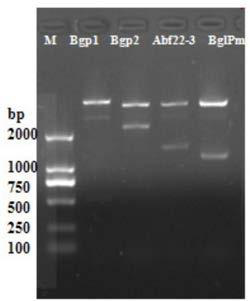

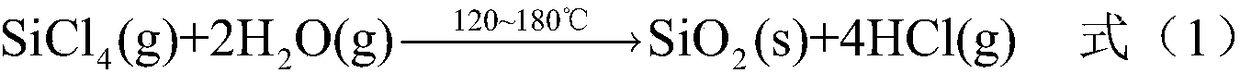

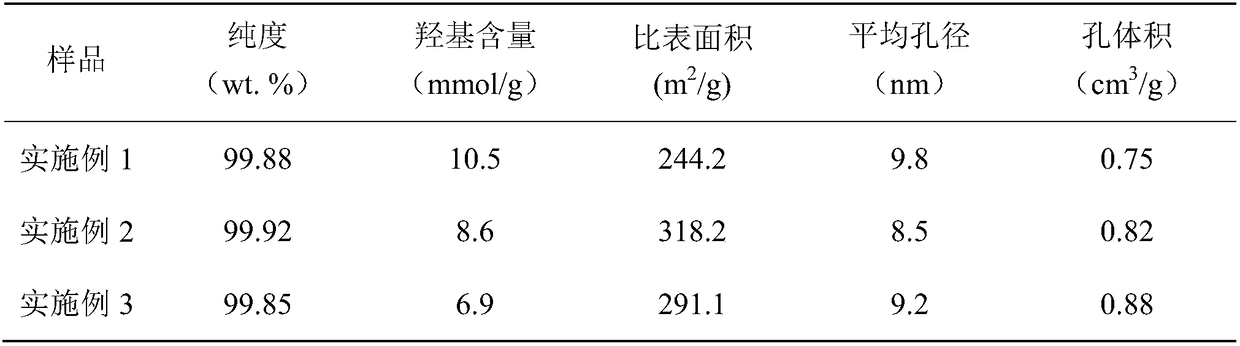

Low-temperature gas phase hydrolysis equipment for preparing white carbon black by using silicon tetrachloride

ActiveCN108217663AReduce reaction energy consumptionReduce manufacturing costSilicaPreparation from chloridesGas phaseCyclonic separation

The invention discloses low-temperature gas phase hydrolysis equipment for preparing white carbon black by using silicon tetrachloride. The low-temperature gas phase hydrolysis equipment comprises a feeding system, a gas carrier system, a gas phase hydrolysis system, a cyclone separation system, a primary deacidification system, a secondary deacidification system and a tertiary deacidification system. Silicon tetrachloride and pure water are continuously introduced according to a molar ratio of 1 : (4 to 8); uniform liquid drops are formed through an atomizing spray head and are vaporized after encountering high-temperature carrier gas, and reaction is carried out in a gas phase hydrolysis tower at 120 to 180 DEG C, so as to produce the white carbon black and hydrogen chloride gas; gas-solid separation of a mixed product is realized through the cyclone separation system, and then drying is performed for 4 hours at 160 DEG C to obtain a white carbon black product; a concentrated hydrochloric acid byproduct is recycled from hydrogen chloride mixed gas through the primary deacidification system and the secondary deacidification system; tail gas is subjected to treatment through the tertiary deacidification system so as to realize pollution-free emission. According to the low-temperature gas phase hydrolysis equipment disclosed by the invention, reaction energy consumption can be reduced, corrosion of the equipment is slowed, and the production cost is reduced; moreover, production capacity of the white carbon black of 100 to 200kg / d and the concentrated hydrochloric acid byproduct are achieved; the prepared white carbon black product is excellent in performance, and has wide production application prospects.

Owner:TSINGHUA UNIV

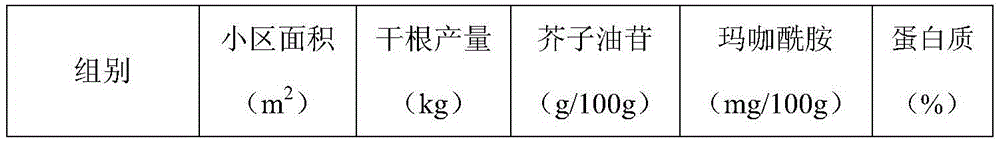

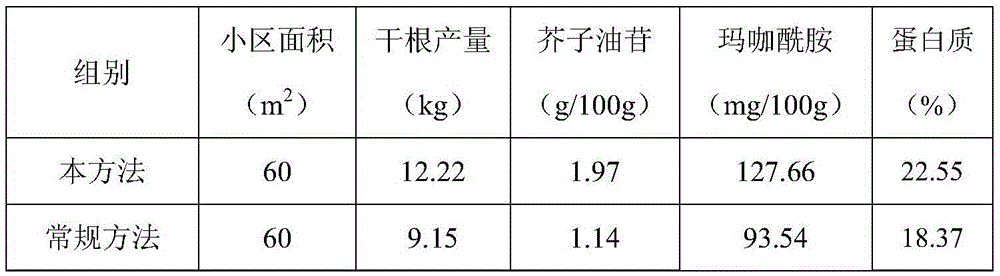

Maca cultivation method

ActiveCN105453883AImprove qualityEasy to synthesizeSuperphosphatesPlant cultivationAnimal scienceGlucosinolate

The invention relates to a Maca cultivation method. The method comprises the following steps that firstly, a 200-400-fold dilute solution of fertilizer A is sprayed to leaves 45-60 days after Maca seedling transplanting, the spraying amount is 1.0-2.0 kg / mu, the fertilizer A is sprayed every 15-20 days, and the total spraying number of times is 3-4; secondly, a 400-600-fold dilute solution of fertilizer B is sprayed to leaves 45-60 days before Maca harvesting, the spraying amount is 0.8-1.5 kg / mu, the fertilizer B is sprayed every 10-15 days, and the total spraying number of times is 1-2. The Maca cultivation method is simple, safe and efficient, the special requirements of Maca for nitrogen phosphorus and potassium, amino acid, microelements, active factors and the like in the growth process can be sufficiently met, the Maca root yield can be increased, the content of the effective active constituent glucosinolate of Maca can be significantly improved, and therefore the Maca quality is obviously improved.

Owner:国珍健康科技(北京)有限公司

Preparation method and application of magnetic Co-V/C3N3 composite supporter particles

InactiveCN110252373AEasy to prepareLow costWater/sewage treatment by irradiationWater treatment compoundsPtru catalystTreated water

The invention discloses a preparation method and application of magnetic Co-V / C3N3 composite carrier particles. The method comprises the following steps: collecting degradation-resistant organic wastewater, adding a magnetic Co-V / C3N4 modified photocatalytic material, and feeding a proper amount of oxygen to initiate degradation reaction of degradation-resistant organic matters under the irradiation of electron beams; and after the reaction is finished, carrying out solid-liquid separation on the magnetic Co-V / C3N4 and a water body under the action of a magnetic field, wherein the supernate is treated water. When the bottom of the reactor needs to be dredged, the magnetic Co-V / C3N4 can be separated from sediments at the bottom under the action of a magnetic field, so that the loss of the catalyst is avoided. The preparation method is carried out at normal temperature and normal pressure, reaction conditions are mild, and the process is simple; the added photocatalytic functional material is environment-friendly and does not generate secondary pollution; the wastewater treatment process is short, the treatment effect is good, and the method is suitable for large-scale treatment of degradation-resistant organic wastewater.

Owner:湖北中和普汇环保科技有限公司

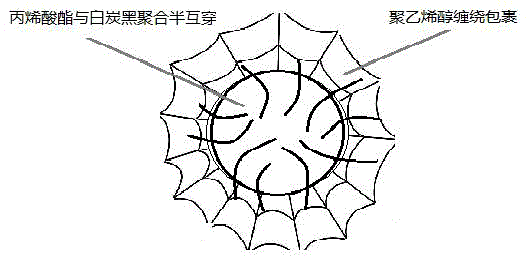

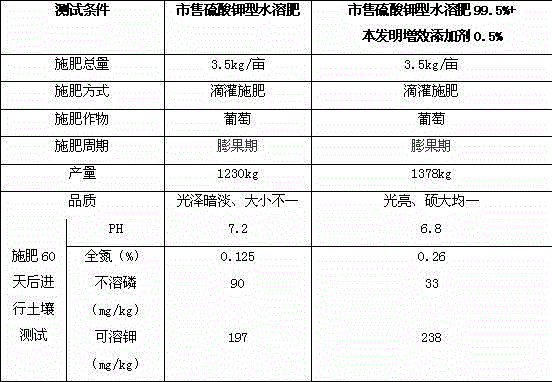

Water-soluble fertilizer synergist additive and preparation method thereof

InactiveCN104140332AAvoid the defects of fertilizer efficiency reductionHydrophilicFertilizer mixturesCalcium hydroxideSoil science

The invention discloses a water-soluble fertilizer synergist additive. The water-soluble fertilizer synergist additive comprises the following components in parts by weight: 70-80 parts of white carbon black, 15-20 parts of acrylate, 10-15 parts of polyvinyl alcohol, 1-2 parts of stabilizing agent, 0.2-0.5 part of initiating agent and 0.2-0.3 part of dispersing agent. By virtue of dry process interpenetrating network, three materials are interpenetrated and wound to form a stable polymer, and the original performance of the materials before interpenetrating is guaranteed; meanwhile, three hydrophilic, adsorbed and water-soluble materials can complement defects in properties each other, so that the water-soluble fertilizer synergist additive can meet hydrophilic, adsorption and water solubility properties when being applied to a water-soluble fertilizer. By virtue of interpenetrating network, water-soluble nutrients in the water-soluble fertilizer are adsorbed, especially acrylate and nutrient ions in the water-soluble fertilizer form a stable compound, nutrients are prevented from being lost, and excellent decomposition on calcium carbonate, calcium hydroxide and calcium phosphate in water is realized, so that efficiency of the water-soluble fertilizer is improved.

Owner:蒋浩

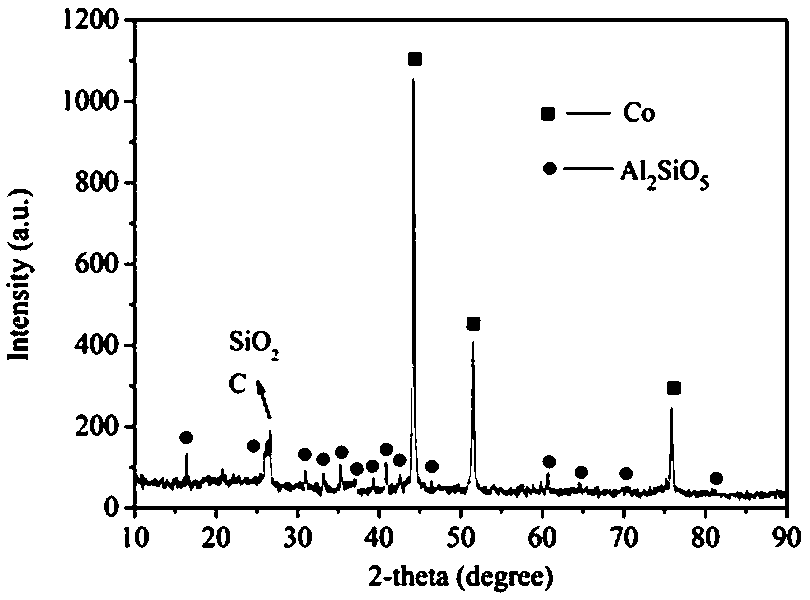

Preparing method for microwave absorbing material based on fly ash

InactiveCN109796191AWide variety of sourcesLow costCeramic materials productionClaywaresCeramic compositeSynthesis methods

The invention relates to a preparing method for a novel microwave absorbing material based on fly ash, and belongs to the technical field of microwave absorbing materials. The preparing method in thetechnical scheme includes the steps that firstly, the fly ash is screened, soluble starch is added, and through an Eirich powerful mixing machine, fly-ash ceramic raw meal balls are synthesized; then,the raw meal balls are screened, dried and then put into a precursor solution dissolving metal ions Co2+, and then the precursor solution is introduced into the raw meal balls with a liquid phase synthesis method; finally, through carbon thermal reduction, the ceramic composite microwave absorbing material carrying a metal simple substance Co is obtained. According to the preparing method for thenovel microwave absorbing material based on the fly ash, the fly ash as a raw material is solid waste, and is wide in source, low in cost and suitable for large-scale production application; as the specific surface area of the fly ash is large, the fly ash has high adsorption activity, and is an ideal carrier material. The ceramic composite wave-absorbing material prepared with the method has board application prospects.

Owner:TAIYUAN UNIVERSITY OF SCIENCE AND TECHNOLOGY

Aquilaria sinensis bundling and agilawood-forming method

ActiveCN111758425APromote infectionThe aroma effect is remarkableHorticulture methodsPlastic filmPlantlet

The invention provides an aquilaria sinensis bundling and agilawood-forming method. The aquilaria sinensis bundling and agilawood-forming method comprises the following steps: S1, selecting an aquilaria sinensis plant meeting agilawood forming conditions as an agilawood forming tree; S2, selecting a bundling point and a bundling iron wire for agilawood forming; S3, cleaning a trunk binding part, and tightly binding the trunk along the binding point by adopting the iron wire until the trunk is attached to the bark; S4, after bundling is completed, smearing an inducer onto the bundling gap of the iron wire until tree burls are generated and wrap the iron wire; S5, after 13 months of bundling, splitting the burls every other half a year to observe the agilawood forming condition; and S6, taking agilawood from the trunk, bundling and sealing the section of a tree stump left on the ground through a plastic film, and culturing sprouting branches for continuous agilawood forming. The agilawood forming method disclosed by the invention is green and environmentally-friendly, saves resources, is friendly to the environment, reduces the cost, simplifies the process, is applicable to large-scale production, and provides a good way for agilawood forming.

Owner:海南润森科技研发有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com