Low-temperature gas phase hydrolysis equipment for preparing white carbon black by using silicon tetrachloride

A gas-phase hydrolysis and silicon tetrachloride technology, which is applied in the preparation of chloride, silicon oxide, silicon dioxide, etc., can solve the problems of high energy consumption for gas-phase silica reaction, reduce import dependence, and high production cost, and achieve Significant product benefits, reduced production costs, and small investment scale

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

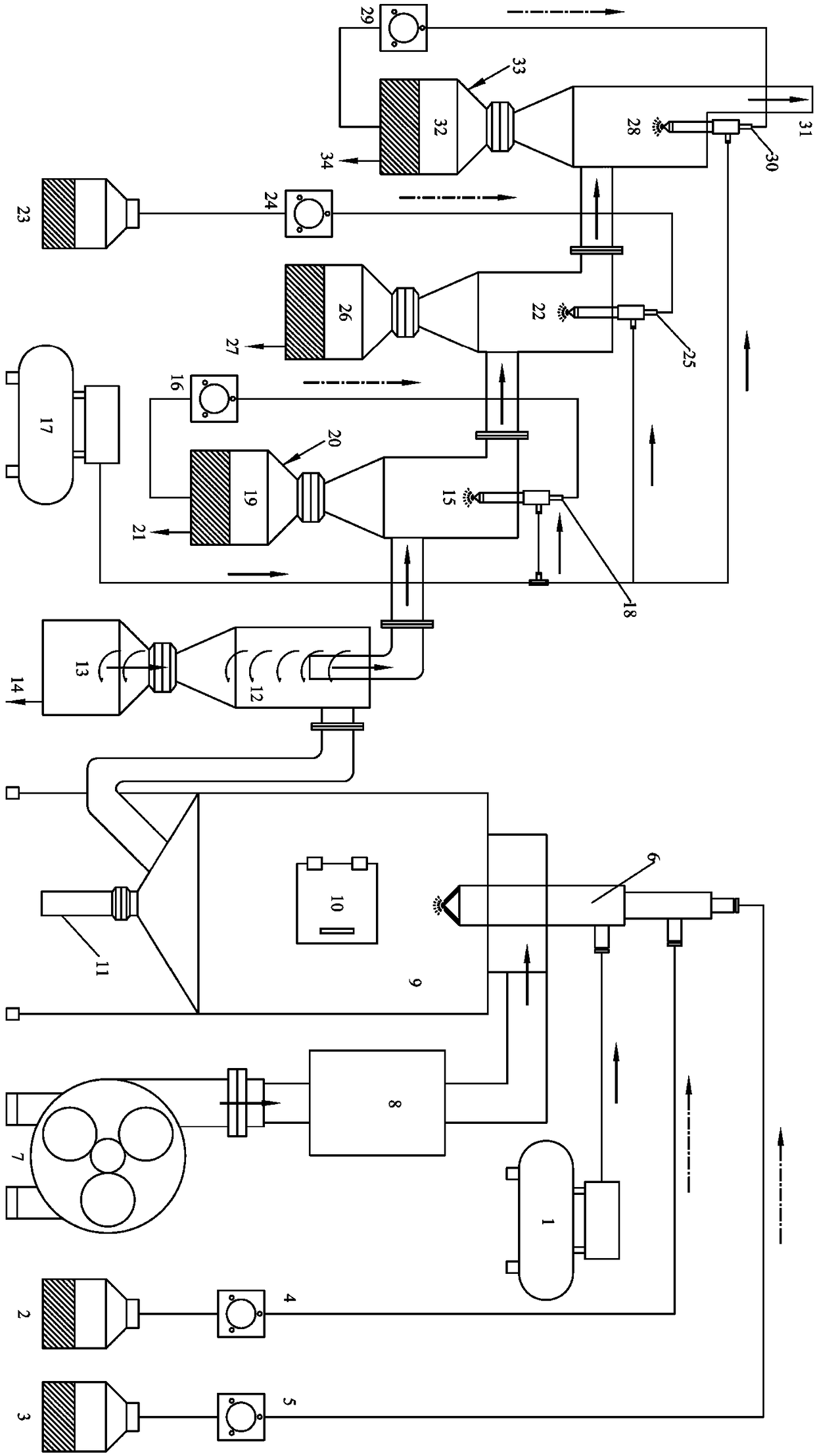

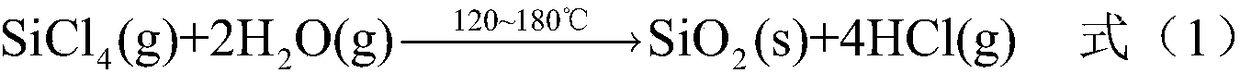

Method used

Image

Examples

Embodiment 1

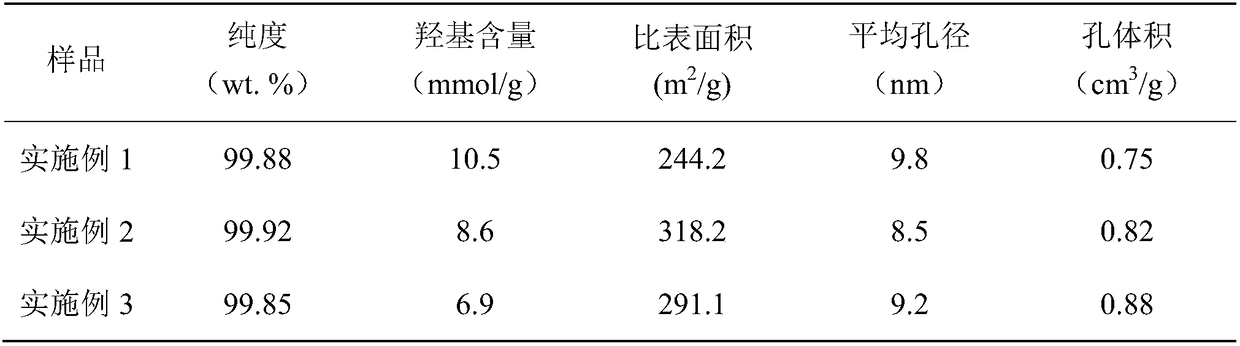

[0037] Described step is identical with above-mentioned equipment workflow, and difference is: the feed rate of silicon tetrachloride is 16L / h in the described step (A), and the feed molar ratio of silicon tetrachloride and pure water is 1:4; In the step (B), the residence time of the reaction material in the gas-phase hydrolysis tower 9 is 2s, and the temperature in the gas-phase hydrolysis tower 9 is 120°C; in the step (C), the temperature in the hydrochloric acid separation tower 12 is 120°C.

Embodiment 2

[0039] Described step is identical with above-mentioned equipment workflow, and difference is: the feed rate of silicon tetrachloride is 16L / h in the described step (A), and the feed molar ratio of silicon tetrachloride and pure water is 1:6; In the step (B), the residence time of the reaction material in the gas-phase hydrolysis tower 9 is 5s, and the temperature in the gas-phase hydrolysis tower 9 is 150°C; in the step (C), the temperature in the hydrochloric acid separation tower 12 is 150°C.

Embodiment 3

[0041] Described step is identical with above-mentioned equipment workflow, and difference is: the feed rate of silicon tetrachloride is 8L / h in the described step (A), and the feed molar ratio of silicon tetrachloride and pure water is 1:8; In the step (B), the residence time of the reaction material in the gas-phase hydrolysis tower 9 is 10s, and the temperature in the gas-phase hydrolysis tower 9 is 180°C; in the step (C), the temperature in the hydrochloric acid separation tower 12 is 180°C.

[0042] Analysis and contrast to embodiment product:

[0043] Adopt X-ray fluorescence spectrometer (U.S. Thermo Fisher, ARL PERFORM'X type) to measure the purity of white carbon black product; Adopt thermogravimetric analyzer (Switzerland Mettler, TGA / DSC 2 type) to measure the hydroxyl content of white carbon black product , the heating rate is 10°C / min; the specific surface area, average pore diameter and pore volume of the silica product are measured using a specific surface and p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com