Synthesis method and application of nanometer SiO2/CaO adsorbent

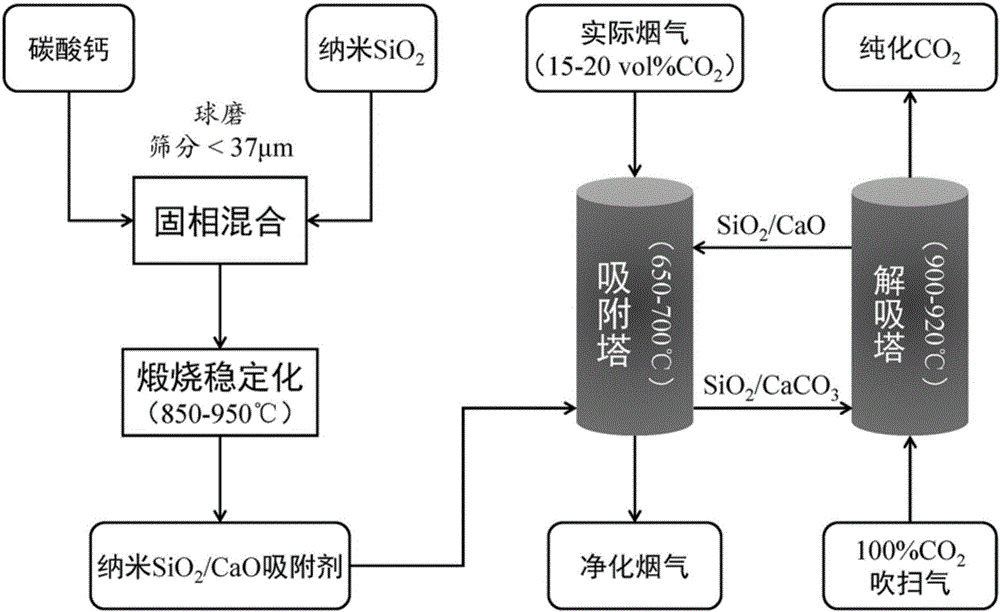

A synthesis method and adsorbent technology, which are applied in the field of industrial source CO2 capture and material synthesis, can solve the problems of complex production process, poor circulation stability of natural calcium-based adsorbent, slow adsorption rate of synthetic calcium-based adsorbent, etc. The effect of large adsorption capacity and high temperature stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

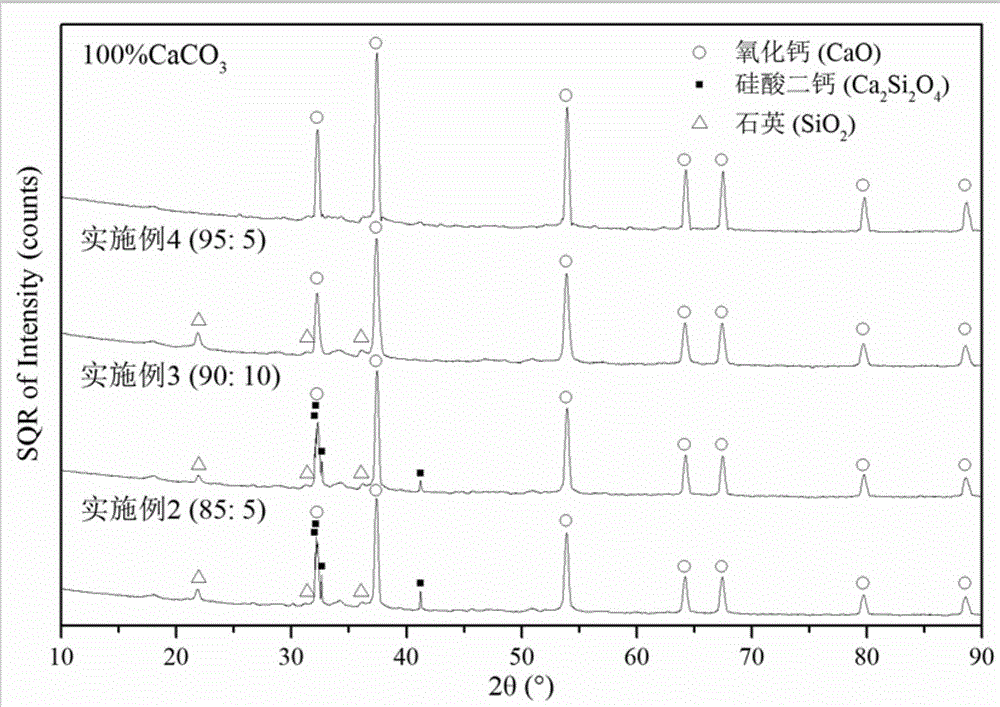

[0028] (A) Using a vertical planetary ball mill to crush calcium carbonate and precipitate nano-SiO 2 (The specific surface area is 342m 2 / g, the pore volume is 0.64cm 3 / g), adjust the speed of the ball mill to be 400rpm, and the ball milling time to be 10min; use a 400-mesh sieve to sieve calcium carbonate and precipitation method nano-SiO 2 , to obtain raw materials with a particle size of less than 37 μm for use.

[0029] (B) Accurately weigh calcium carbonate 142.8g after step (A) sieve and precipitate method nanometer SiO 2 20g (the calcium carbonate quality is based on the contained CaO mass, and the mass ratio is 80:20), using an agate mortar to mix calcium carbonate and precipitation method nano-SiO 2 Mix well and grind for 10 minutes.

[0030] (C) Calcium carbonate after grinding in step (B) and precipitation method nano-SiO 2 The mixture was placed in a tube furnace and heated at a rate of 15 °C / min under N 2 Calcined at 850°C for 6 hours in a gas atmosphere...

Embodiment 2

[0033] (A) Using a vertical planetary ball mill to crush calcium carbonate and precipitate nano-SiO 2 (The specific surface area is 342m 2 / g, the pore volume is 0.64cm 3 / g), adjust the speed of the ball mill to be 400rpm, and the ball milling time to be 10min; use a 400-mesh sieve to sieve calcium carbonate and precipitation method nano-SiO 2 , to obtain raw materials with a particle size of less than 37 μm for use.

[0034] (B) Accurately weigh calcium carbonate 151.7g after step (A) sieve and precipitate method nanometer SiO 2 15g (the quality of calcium carbonate is based on the contained CaO mass, and the mass ratio is 85:15), using an agate mortar to mix calcium carbonate and precipitation method nano-SiO 2 Mix well and grind for 10 minutes.

[0035] (C) Calcium carbonate after grinding in step (B) and precipitation method nano-SiO 2 The mixture was placed in a tube furnace and heated at a rate of 15 °C / min under N 2 Calcined at 900 °C for 4 h in a gas atmosphere...

Embodiment 3

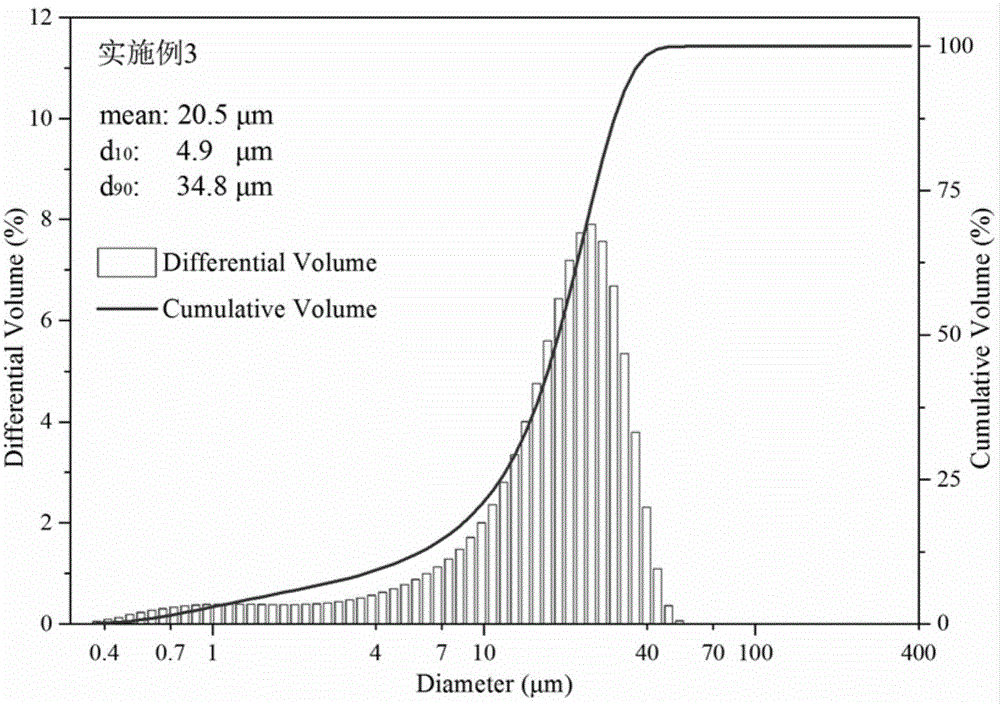

[0038] (A) Using a vertical planetary ball mill to crush calcium carbonate and precipitate nano-SiO 2 (The specific surface area is 342m 2 / g, the pore volume is 0.64cm 3 / g), adjust the speed of the ball mill to be 350rpm, and the ball milling time to be 20min; use a 400-mesh sieve to sieve calcium carbonate and precipitation method nano-SiO 2 , to obtain raw materials with a particle size of less than 37 μm for use.

[0039] (B) Accurately weigh the calcium carbonate 160.6g after step (A) sieving and the nanometer SiO of precipitation method 2 10g (the calcium carbonate quality is based on the contained CaO mass, and the mass ratio is 90:10), using an agate mortar to mix calcium carbonate and precipitation method nano-SiO 2 Thoroughly mix and grind for 20 minutes.

[0040] (C) Calcium carbonate after grinding in step (B) and precipitation method nano-SiO 2 The mixture was placed in a tube furnace, heated at a rate of 15 °C / min, and calcined at 900 °C for 2 h in an Ar g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com