Water-soluble fertilizer synergist additive and preparation method thereof

A technology of synergistic additives and water-soluble fertilizers, applied in fertilization devices, fertilizer mixtures, applications, etc., can solve the problems of difficult large-scale use, limited nutrient fixation, and easy pollution of water bodies, so as to prevent nutrient loss, improve fertilizer utilization, The effect of preventing fertilizer loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

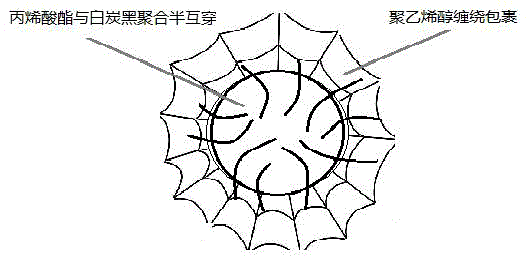

[0039] (1) 70 parts by weight of fumed silica colloidal nanoparticles with a particle diameter of 50nm, 20 parts by weight of methyl acrylate with a molecular weight of 1000-1500, and 10 parts by weight of polyethylene with a molecular weight of 120,000 and a degree of alcoholysis of 88% Alcohol and 0.2 parts by weight of polydimethylsiloxane dispersant are uniformly mixed in a high-speed mixer, and then sent to a reflective pulverizer through mechanical pulverization and gas collision, and the material forms a powder with an interpenetrating network structure at a dispersion speed of 1200rpm. body.

[0040] (2) Put the powder obtained in step (2) and 0.2 parts by weight of copper hydrogen peroxide into the reaction kettle, pass nitrogen protection in the dry powder state, heat to 60-80°C, and stir the reaction at a high speed of 400rpm with the stirring blade 45min, obtain composite polymer;

[0041] (3) Mix the composite polymer obtained in step (2) with 2 parts by weight o...

Embodiment 2

[0047] (1) 75 parts by weight of fumed silica colloidal nanoparticles with a particle diameter of 80nm, 18 parts by weight of ethyl methacrylate with a molecular weight of 1000-1500, 20 parts by weight of a medium-polymerization degree with a molecular weight of 130,000 and a degree of alcoholysis of 88%. Polyvinyl alcohol and 0.3 parts by weight of polyoxyethylene sorbitan monooleate dispersant are uniformly mixed in a high-speed mixer and then sent to a reflective pulverizer through mechanical pulverization and gas collisions, and the materials are formed into mutual particles at a dispersion speed of 1300rpm. Powder with network structure.

[0048] (2) Send the powder obtained in step (2) and 0.2 parts by weight of ferric hydrogen peroxide into the reaction kettle, pass nitrogen protection in the dry powder state, heat to 60-80°C, and stir the reaction at a high speed of 500rpm with the stirring blade 40min, obtain composite polymer;

[0049] (3) Mixing the composite polym...

Embodiment 3

[0051] (1) 80 parts by weight of fumed silica colloidal nanoparticles with a particle diameter of 60nm, 15 parts by weight of propyl acrylate with a molecular weight of 1000-1500, and 15 parts by weight of polyethylene with a molecular weight of 150,000 and a degree of alcoholysis of 88% Alcohol and 0.2 parts by weight of sorbitan monopalmitic acid ester dispersant are mixed uniformly in a high-speed mixer and then sent to a reflective pulverizer through mechanical pulverization and gas collision, and the material forms an interpenetrating network structure powder at a dispersion speed of 1500rpm body.

[0052] (2) Put the powder obtained in step (2) and 0.5 parts by weight of ferric chloride into the reaction kettle, pass nitrogen protection in the dry powder state, heat to 60-80°C, stir the reaction at a high speed of 500rpm for 30min , to obtain composite polymer;

[0053] (3) Mix the composite polymer obtained in step (2) with 2 parts by weight of a copolymer of 2-acrylam...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com