Method for preparing negative pole slurry for lithium ion batteries

A lithium-ion battery and negative electrode slurry technology, which is applied in the direction of battery electrodes, circuits, electrical components, etc., can solve the problems that affect the widespread production and popularization of lithium-ion batteries, increase the production cost of negative electrode slurry, and poor slurry uniformity and stability. , to achieve the effect of improving market application prospects, significant production practice significance, and ensuring uniformity and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

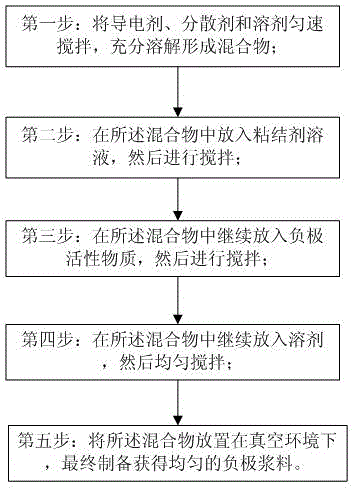

[0028] see figure 1 , the invention provides a kind of preparation method of negative electrode slurry of lithium ion battery, comprises the following steps:

[0029] The first step: Stir the conductive agent, dispersant and solvent with a mass ratio of 1:3:23 at a constant speed, and fully dissolve to form a mixture;

[0030] Second step: put binder solution in the mixture, the mass ratio between the mixture and binder solution is 7: 8 and then stir;

[0031] The third step: continue to put negative electrode active material in the mixture, the mass ratio between the mixture and the negative electrode active material is 2: 3, then stir;

[0032] The fourth step: continue to put solvent in the mixture, the mass ratio between the mixture and the solvent is 6.5:1, and then stir evenly;

[0033] Step 5: placing the mixture in a vacuum environment to finally prepare a uniform negative electrode slurry.

[0034] In the present invention, in the first step, the conductive agent i...

Embodiment 1

[0046] Mix PVDF (as a binder) and NMP (as a solvent) with a mass ratio of 12:88 and stir at a high speed of 200 to 600 rpm for 4 hours to form a uniform and transparent binder liquid, and then set aside for 4- 8 hours standby;

[0047] Next, mix the conductive agent, dispersant and NMP solvent with a mass ratio of 1: 3: 23, and stir at a low speed of 20 to 40 rpm for at least 60 min;

[0048] Then add the initially prepared binder liquid to the above mixture, first stir at a low speed of 20-40 rpm for 30 minutes by using a mixer, and then stir at a high speed of 2500-3000 rpm for 30 minutes;

[0049] Then, continue to add the artificial graphite as the negative electrode active material into the above-mentioned mixture, the mass ratio between the mixture and the negative electrode active material is 2: 3, stir at a low speed of 20~40 rpm for 15min, then stir at 2500~ Stir at a high speed of 3000 rpm for 60 minutes;

[0050]Then, add N-methylpyrrolidone solvent to the mixture...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com