Micromixer apparatus and methods of using same

a micro-mixer and apparatus technology, applied in the field of fluid dynamics, can solve the problems of difficult cleaning of the device for repeated use, less attractive to bioanalysis system designers, and troublesome biologic samples

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

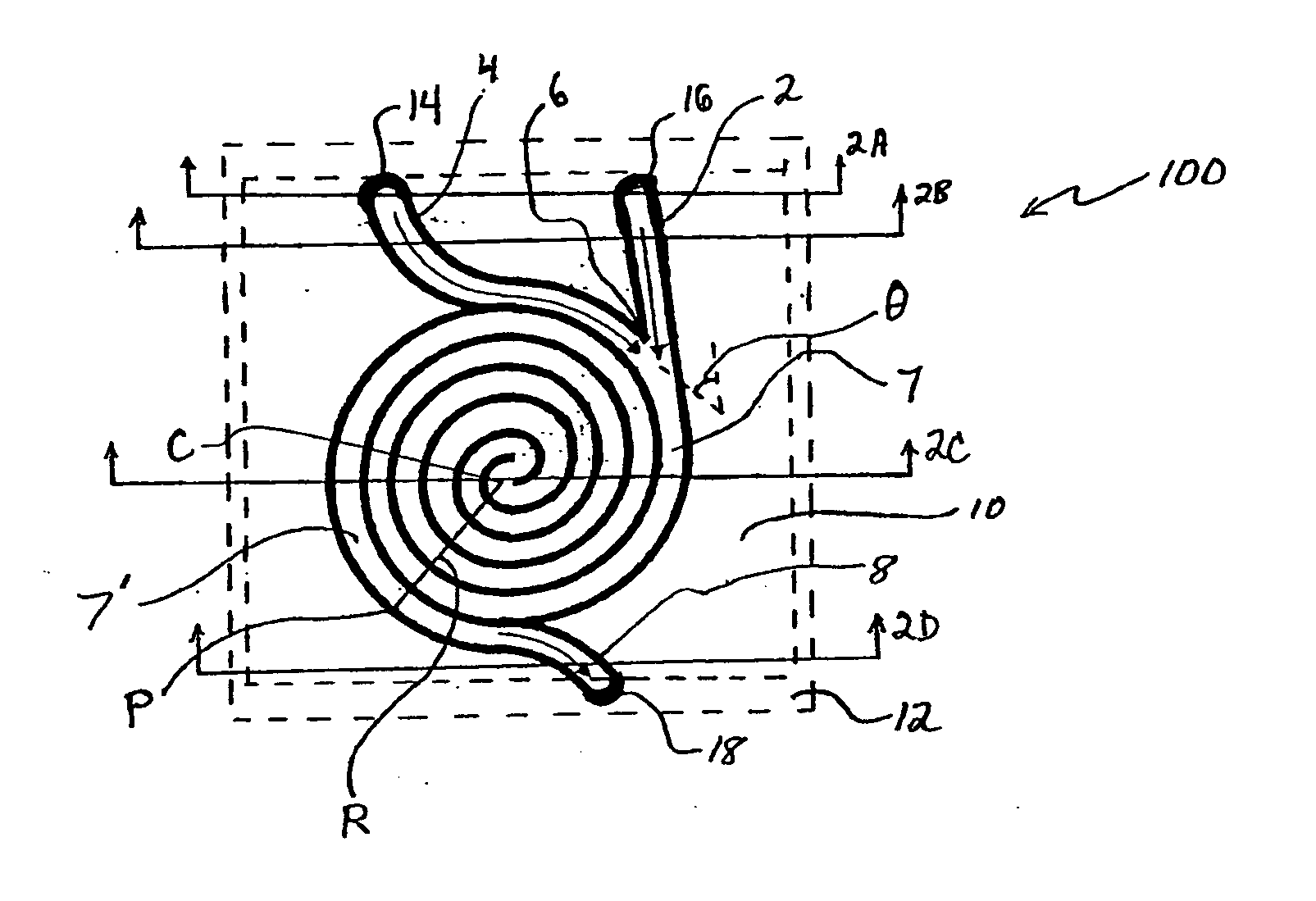

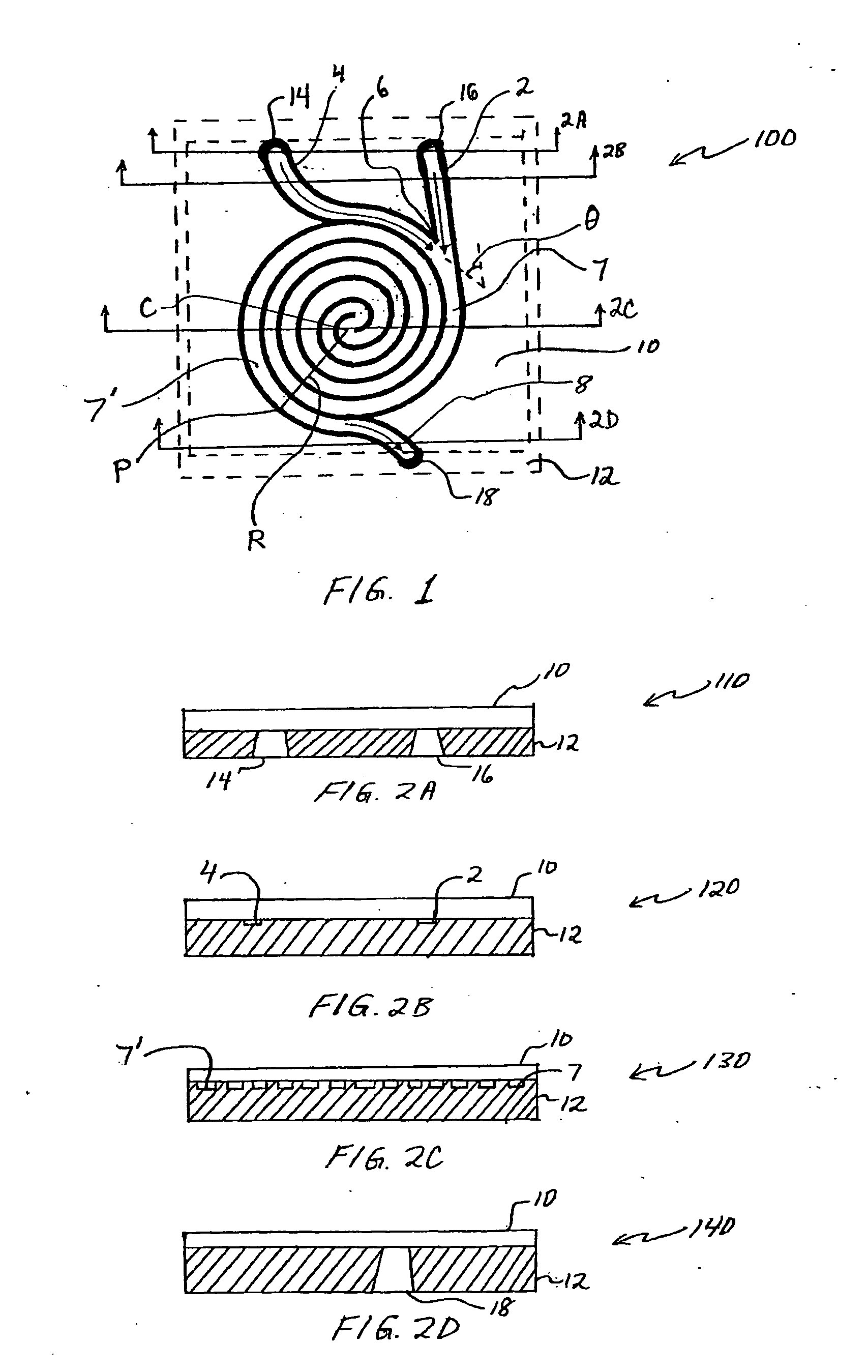

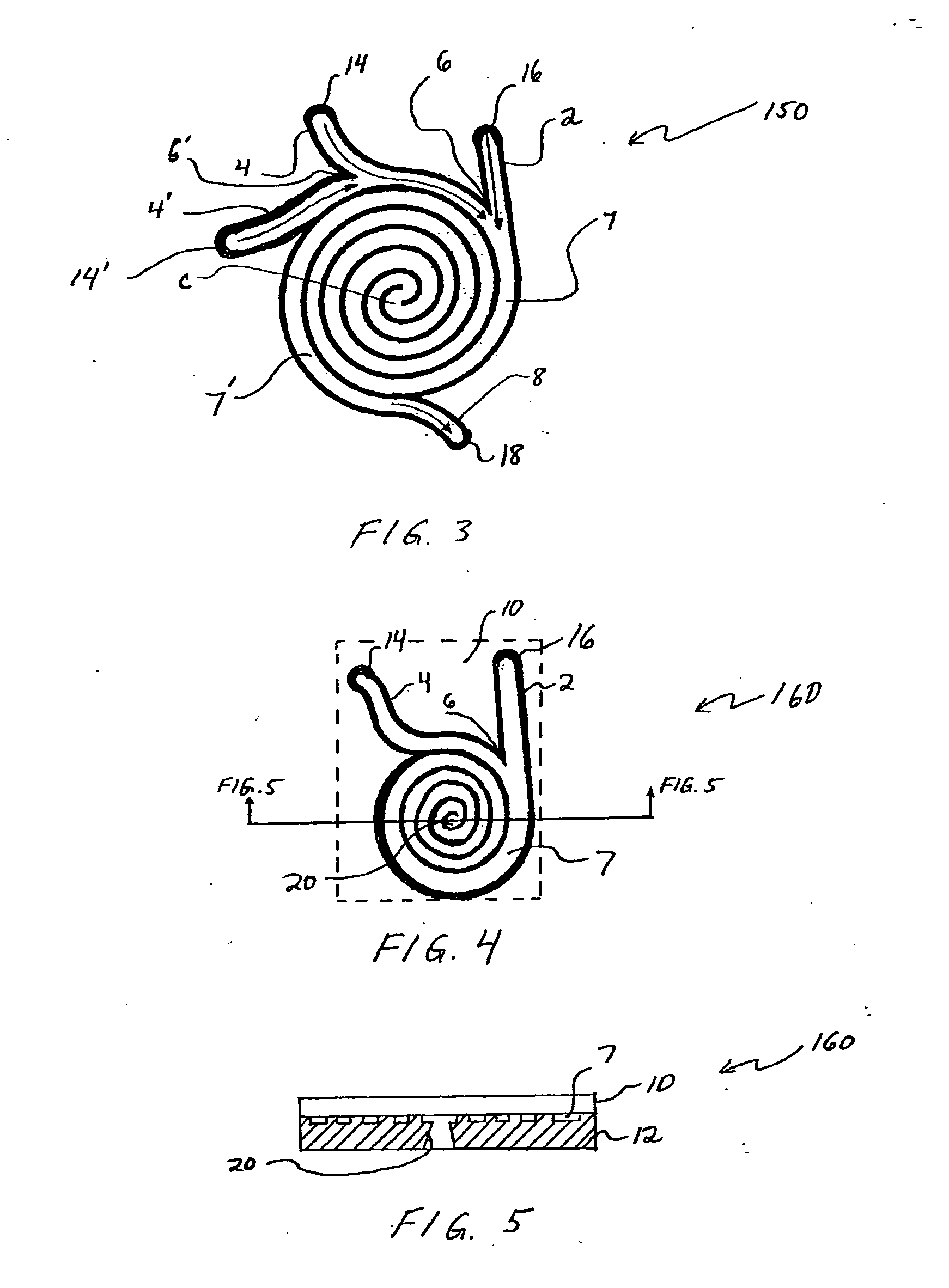

[0033] The inventors have developed unique apparatus and methods of using same to mix fluids. Apparatus and methods of use of the invention rely on mixing resulting from a centrifugally enhanced diffusion process. The non-uniform velocity profile across the section of the mixer arises from the combination of viscous forces and centrifugal (inertial in the radial direction) forces. The viscous forces give rise to the typical quadratic velocity profile whilst the centrifugal forces are proportional to the tangential velocity, the fluid mass, and the radius of the mixing channel from the center of the apparatus to the point of interest. The solution of all forces on the liquid results in a flow pattern that continuously circulates the liquid from an inner inlet channel into the fluid entering a second, or outer channel. Depending on the size of the apparatus and the intent of the user, more than one fluid can be mixed in apparatus of the invention.

[0034] Referring now to the drawing f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com