Method for manufacturing three-dimensional micromixer microfluidic chip

A technology of microfluidic chips and manufacturing methods, applied in chemical instruments and methods, laboratory containers, laboratory utensils, etc., can solve problems such as complex processes, and achieve simple operation, good reproducibility, and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1、3

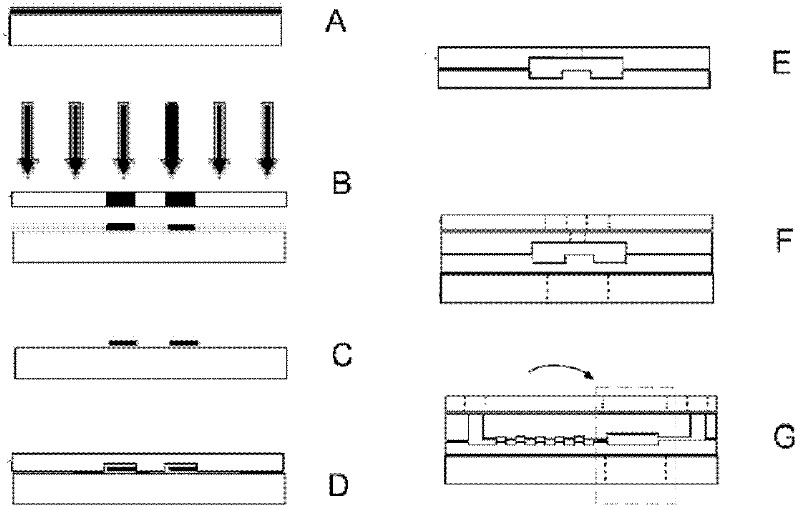

[0031] Example 1, Fabrication of 3D micro-mixed microfluidic chip

[0032] (1) Design the microchannel pattern of the 3D micro-hybrid microfluidic chip with Freehand software, the width is designed to be 100 μm, and the mask is prepared by laser phototypesetting;

[0033] (2) Piranha washing solution (98% (wt) H 2 SO 4 with 30% (wt) H 2 o 2 The volume ratio is 3:1) heated, boiled and cleaned for 30min, rinsed with distilled water, dried and placed in a KW-4A glue homogenizer, and coated with a layer of SU-8 photolithography with a thickness of about 50μm at a speed of 4000r / min. glue (model SU-82035), such as figure 1As shown in step A; after that, let the glass sheet coated with light glue stand for 30 minutes to make it flow naturally and adjust the plane evenly; place the glass sheet coated with glue in a constant temperature hot plate oven for 20 minutes at 65°C, and immediately heat up the oven to 95°C, after the temperature of the oven is constant, bake it for 10 mi...

Embodiment 2

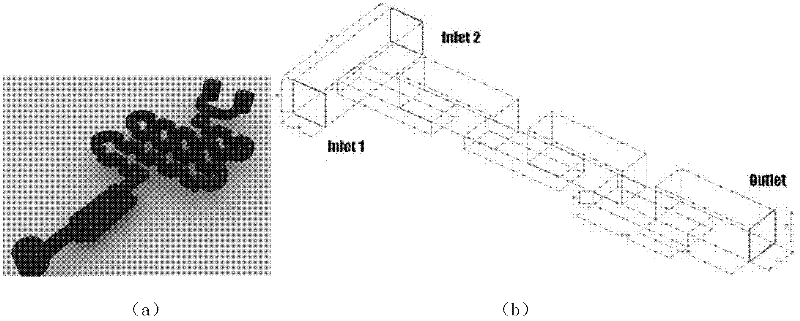

[0037] The 3D micro-mixed microfluidic chip made in Example 2 and Example 1 is used in combination with an ultraviolet detector

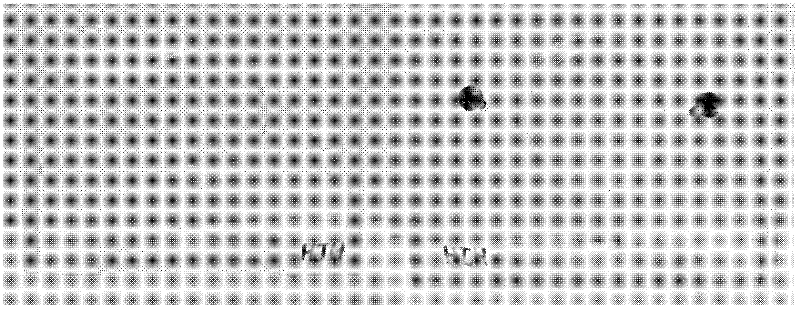

[0038] Assembly of 3D micro-hybrid microfluidic chip-ultraviolet detector: 3D micro-hybrid microfluidic chip needs to work under the positive pressure drive of the micro-injection pump; The silicone tube is used as the catheter to transport the sample, and the polyurethane plastic tube with an inner and outer diameter of 2×3 mm is used as the sample connection port, and the polyurethane tube and the glass chip sample port are bonded with epoxy AB glue (1:1, v / v). and 1000 μm micro-sampler sample injection, directly connected to the sampler needle with a silicone tube, with TS-1A micro-syringe pump to control the input flow (flow rate) to directly drive the sample injection; in addition, the 3D micro-mix micro The fluidic chip is loaded into a self-designed plexiglass mold, so that the detection area of the 3D micro-hybrid microfluidic chip is alig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com