PCD (Poly Crystal Diamond) molding cutter for machining belt pulley

A technology of forming knives and pulleys, which is applied to metal processing equipment, cutting tools for milling machines, workpieces, etc., can solve the problems of lower forming processing efficiency, large errors in roundness and straightness, and non-wear resistance, and achieve improved Machining efficiency and quality, improved tool wear resistance, smooth pulley edges

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The specific embodiments of the present invention will be further described below in conjunction with the drawings.

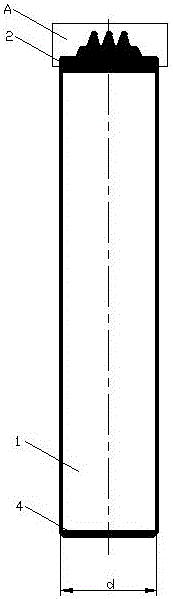

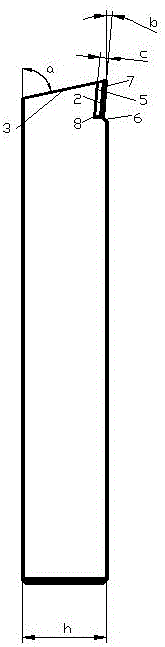

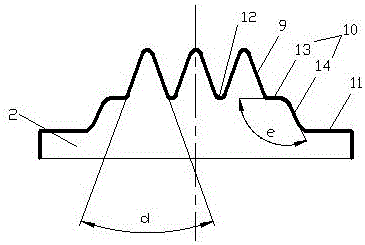

[0023] A PCD forming knife for belt pulley processing, comprising a knife handle and a PCD knife head, wherein the thickness of the knife handle is h, the width of the knife handle is d, h: d=20:23, and the top of the knife handle A cut surface is provided, the inclined included angle a between the cut surface and the side wall of the knife handle is 75°, the bottom of the knife handle is provided with a chamfering table, the top of the side wall of the knife handle is provided with a groove, and the groove There is a chamfered edge between the bottom and the side wall of the handle;

[0024] The PCD cutter head is placed in the groove, the PCD cutter head has a rake face and a flank face, the rake face and the shank side wall are arranged obliquely, and the rake face and the shank side wall are The inclination angle b between the flank surface is 5°, the fl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com