A kind of multi-element microalloyed high-strength heat-resistant rare earth magnesium alloy and preparation method thereof

A rare earth magnesium and magnesium alloy technology, applied in the field of rare earth magnesium alloy materials, can solve problems such as difficulty in meeting the needs of precision manufacturing, deterioration of alloy process performance, and impact on the scope of application, achieve excellent room temperature and high temperature mechanical properties, and improve microstructure. appearance, improve the effect of grain refinement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0110] The present invention provides a method for preparing the rare earth magnesium alloy according to the above technical solution or the casting molding method of the rare earth magnesium alloy according to any one of the above technical solutions, that is, the preparation method of the as-cast rare earth magnesium alloy, comprising the following steps:

[0111] 1) heating Mg, Ag, Zn, Mg-RE master alloy after melting, adding Mg-Zr master alloy and Mg-Sc master alloy for refining to obtain a melt;

[0112] 2) the molten material obtained in the above steps is cooled and left to stand, and then cast to obtain a magnesium alloy ingot;

[0113] 3) subjecting the magnesium alloy ingot obtained in the above steps to a solution treatment and then to an aging treatment to obtain a rare earth magnesium alloy.

[0114] The present invention can correspond to the composition, category and addition ratio of the raw materials required in the above preparation process, as well as the co...

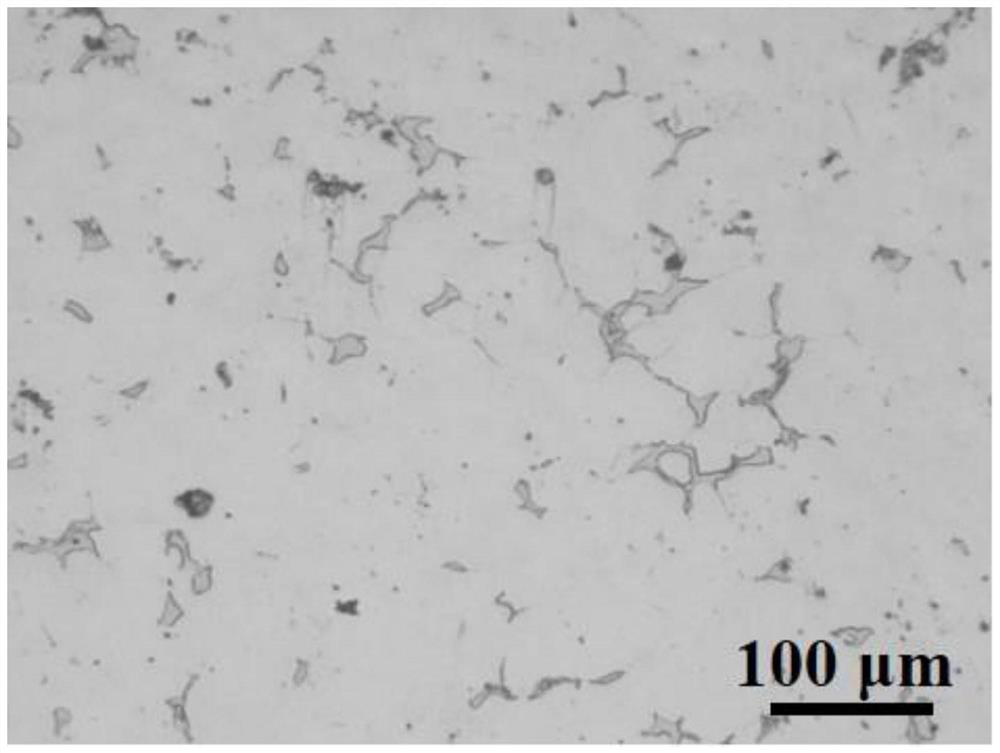

Embodiment 1

[0171] The high-strength and heat-resistant magnesium alloy of this embodiment is composed of the following components by mass percentage: Gd: 8.5wt.%, Y: 2.5wt.%, Ag: 0.5wt.%, Sc: 0.01wt.%, Zr: 0.45wt. %, Zn: 0.2 wt.%, the balance is Mg and inevitable impurities.

[0172] The casting molding preparation of the high-strength and heat-resistant magnesium alloy of the present embodiment includes the following steps:

[0173] (1) Preparation of magnesium alloy ingots: pure Mg, pure Ag, pure Zn, Mg-Zr master alloy, Mg-Sc master alloy, Mg-RE (20-30wt.%) master alloy are batched according to the above rated mass percentage, Wash, dry and preheat.

[0174] (2) Put pure Mg, pure Ag, pure Zn, Mg-RE (20-30wt.%) into the crucible to melt and heat up to 740℃, then add Mg-Zr master alloy and Mg-Sc master alloy to stir and mix with Refined.

[0175] (3) The melt was cooled to 710° C. for about 40 minutes, followed by casting.

[0176] (4) Solution treatment: heat treatment at 520°C for ...

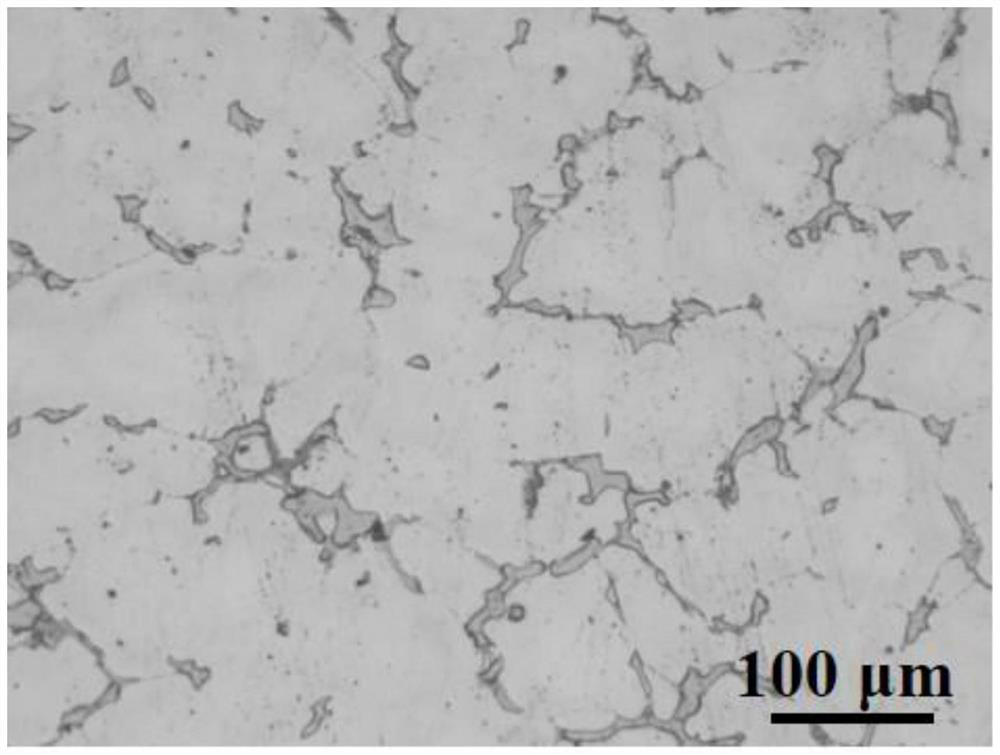

Embodiment 2

[0184] The difference between Example 2 and Example 1 is that the high-strength and heat-resistant magnesium alloy is composed of the following components by mass: Gd: 9.5wt.%, Y: 3wt.%, Ag: 0.7wt.%, Sc: 0.04wt% %, Zr: 0.45 wt. %, Zn: 0.2 wt. %, and the balance is Mg and inevitable impurities. Solution treatment: heat treatment at 510℃ for 12h, and then air-cool to room temperature. Aging treatment: heat treatment at 225℃ for 48h, and then air-cool to room temperature.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com