C/SiC ceramic matrix composite spring and preparation method thereof

A composite material and ceramic-based technology, applied in the field of high temperature sealing of thermal protection systems, can solve the problems of high hardness of ceramic materials, decreased oxidation resistance, difficult processing and preparation, etc., and achieves low cost, simple preparation process and equipment requirements, and preparation temperature. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

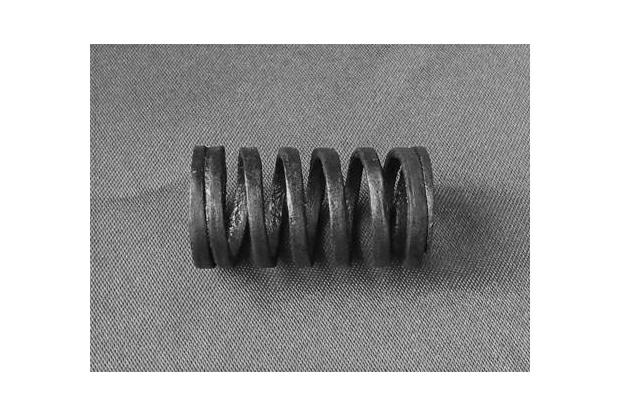

[0028] a kind of like figure 1 , figure 2 The shown C / SiC ceramic matrix composite material spring of the present invention, this spring is to be matrix with silicon carbide, with the carbon fiber of volume fraction about 34% as reinforcing phase, the surface of spring is deposited with SiC coating; The stiffness reaches 3.5N / mm, and the stiffness still reaches 2.6N / mm in the air at 1000°C, and the stiffness retention rate exceeds 74%.

[0029] The C / SiC ceramic matrix composite material spring of this embodiment is prepared through the following steps:

[0030] (1) Forming of spring prefabricated parts: After 14 bundles of carbon fibers are bundled, twisted and plied, they are added to the PCS / DVB resin system containing curing agent for impregnation, wherein the mass ratio of polycarbosilane, divinylbenzene and curing agent is 1 : 1: 0.02, winding the impregnated carbon fiber preform on a paraffin wax mold or a water-soluble mold with a diameter of 16mm, and cross-linking...

Embodiment 2

[0035] A C / SiC ceramic matrix composite spring of the present invention, the spring is based on silicon carbide, carbon fiber with a volume fraction of about 42% is used as a reinforcement phase, and the surface of the spring is deposited with a SiC coating; The stiffness reaches 7.5N / mm, and the stiffness still reaches 6.3N / mm in the air at 1000°C, and the stiffness retention rate reaches 84%.

[0036] The C / SiC ceramic matrix composite material spring of this embodiment is prepared through the following steps:

[0037] (1) Forming of spring prefabricated parts: 20 bundles of carbon fibers are woven and wound in situ on a paraffin wax mold with a diameter of 20mm, and then impregnated in epoxy resin-acetone solution containing curing agent, in which epoxy resin, acetone, The mass ratio of the curing agent is 1:1.5:0.1, and the impregnated carbon fiber preform is cross-linked and cured at room temperature for 5 hours to obtain a spring preform;

[0038] (2) Forming of rough s...

Embodiment 3

[0042] A kind of C / SiC ceramic matrix composite material spring of the present invention, this spring is to be matrix with silicon carbide, with the carbon fiber of volume fraction about 37% as reinforcing phase, the surface of spring is deposited with SiC coating; The rigidity of this spring under room temperature It reaches 5.6N / mm, and the stiffness still reaches 4.4N / mm in the air at 1000°C, and the stiffness retention rate exceeds 78%.

[0043] The C / SiC ceramic matrix composite material spring of this embodiment is prepared through the following steps:

[0044] (1) Forming of spring prefabricated parts: 16 bundles of carbon fibers are woven and wound in situ on a water-soluble mold with a diameter of 20mm, and then added to a phenolic resin-ethanol solution containing a curing agent for impregnation. The mass ratio of the agent is 1:2:0.05, and the impregnated carbon fiber preform is cross-linked and cured at room temperature for 3 hours to obtain a spring preform;

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| service temperature | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com