Garbage harmless treatment equipment for urban construction

A technology for urban construction and garbage, applied in grain processing, lighting and heating equipment, applications, etc., can solve the problems of brushing, water consumption, environmental pollution, etc., to improve safety and suppress dust rising.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

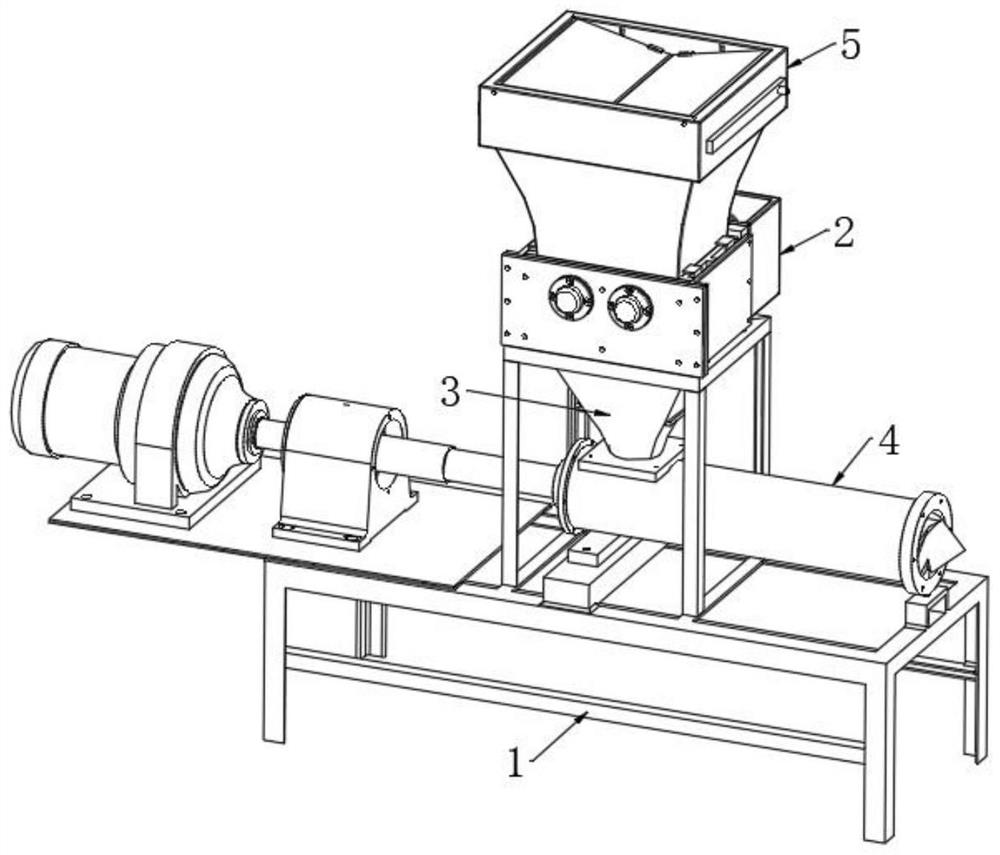

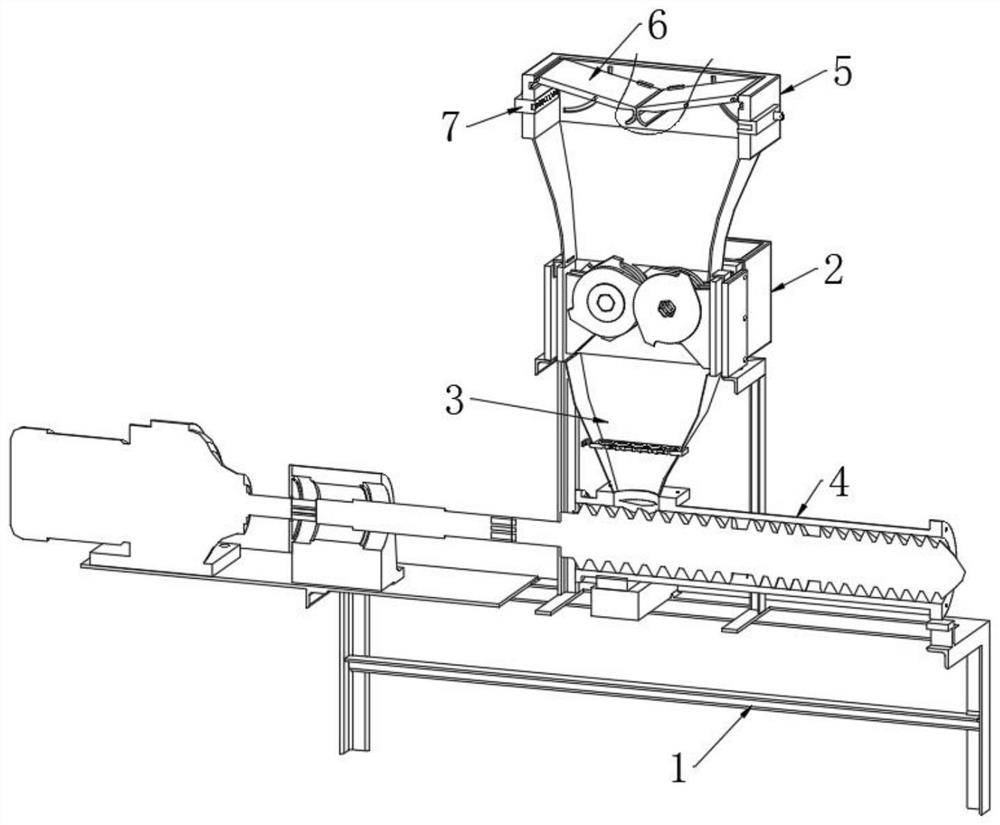

[0036] refer to Figure 1-10 In this embodiment, a kind of harmless treatment equipment for urban construction garbage is proposed, including a frame 1, a crushing assembly 2 for crushing masonry and a slow discharge assembly 4 for slowly discharging masonry particles are installed on the top of the frame 1 , between the crushing assembly 2 and the slow discharge assembly 4 is connected the same iron removal assembly 3 that can absorb iron and steel scraps, the top of the crushing assembly 2 is installed with a feed hopper 5 for feeding, and the feed hopper 5 is rotated and installed There are two symmetrically distributed buffer protection components 6 that slow down the falling speed of masonry and prevent masonry particles from splashing. Air curtains 7 are symmetrically installed on the inner walls of both sides of the feed hopper 5 to prevent dust from escaping. The wind below the buffer protection assembly 6 forms a vortex that can gather dust.

Embodiment 2

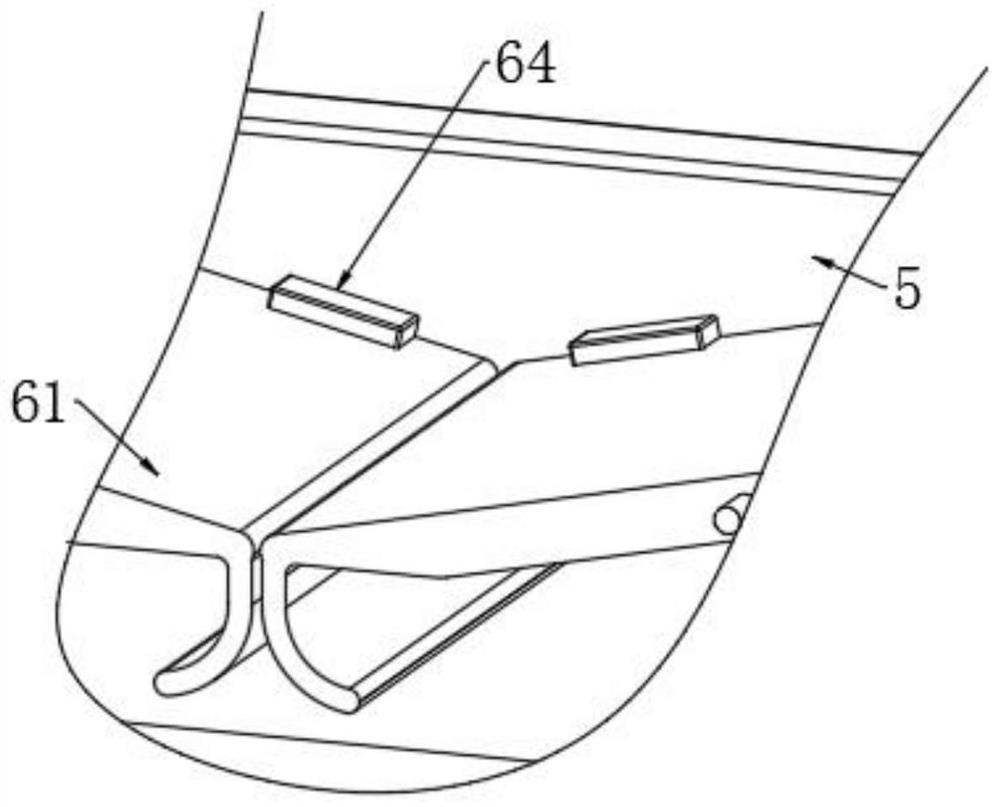

[0038]The buffer protection assembly 6 includes two rotating shafts 65 that are fixedly connected to the inner wall of the feed hopper 5. The two rotating shafts 65 are provided with baffles 61 that are sealingly and slidingly connected to the inner wall of the feeding hopper 5. The two baffles 61 are in the form of The two baffles 61 are distributed in a V shape, and the sides of the two baffles 61 that are close to each other are hermetically connected together. The inner walls on both sides of the frame 1 are equipped with a reset assembly 63 that resets the baffles 61 that have moved down.

[0039] It should be noted that, if Figure 5 As shown, since the two baffles 61 are distributed in a V shape, it is only necessary to throw the masonry above the two baffles 61, and then the masonry will automatically slide to the gap between the two baffles 61 under the action of gravity. Between the gap, after the adjacent ends of the two baffles 61 are pressed down by the masonry, t...

Embodiment 3

[0045] The sides of the two baffles 61 that are close to each other are provided with an arc portion 67 .

[0046] It should be noted that, if Figure 5 As shown, the wind blown by the air curtain 7 first falls on the bottom of the inclined baffle plate 61, and then the wind enters the arc portion 67 and rotates in the arc portion 67 and turns around and blows to one side of the air curtain 7 Therefore, the wind blown by the air curtain 7 can form a vortex below the baffle 61, and the upward dust generated by the broken masonry of the crushing assembly 2 will follow the vortex and completely gather under the baffle 61, ensuring that the dust generated during the crushing process can It is completely under the two baffles 61 to ensure that the dust will not escape from the feed hopper 5, which improves the sanitation in the process of crushing masonry, and when there is too much dust in the eddy current under the baffles 61, the redundant The dust will fall down under its own ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com