Water based paint with mirror surface effect and preparation method thereof

A technology of water-based paint and water-based acrylic, applied in the direction of coating, etc., can solve problems such as complex processing methods, and achieve the effects of high hardness, scratch resistance, good leveling, and high activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

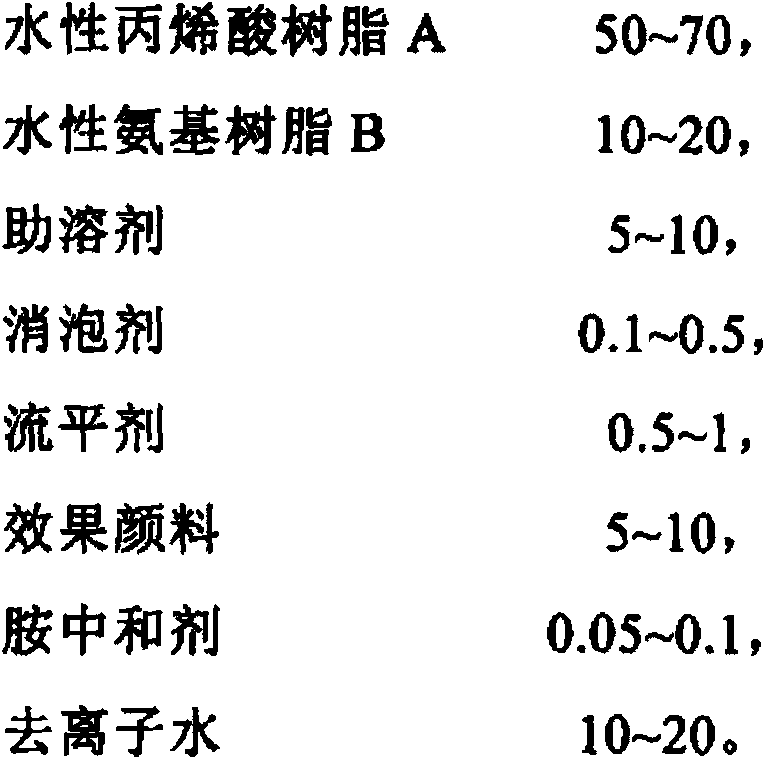

[0028] A kind of water-based paint with mirror effect, by weight, the paint is made of the following components:

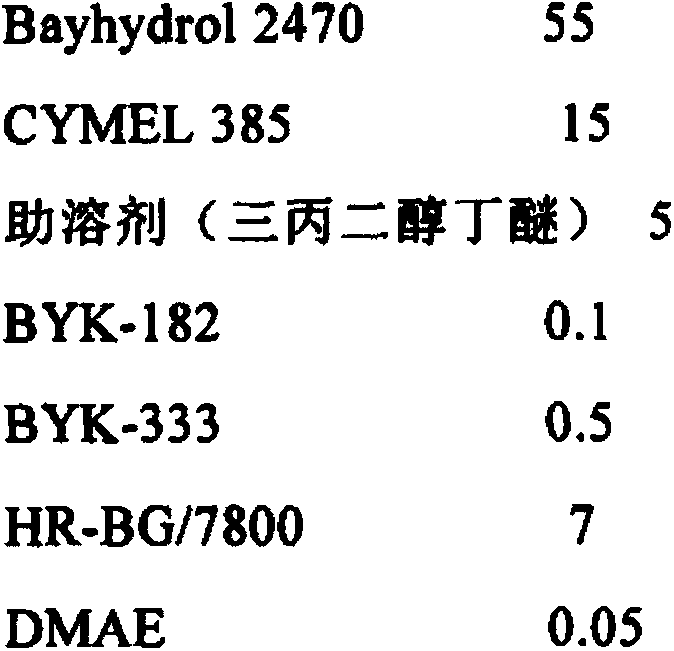

[0029]

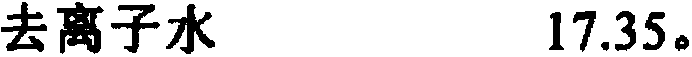

[0030]

[0031] The preparation method of the above-mentioned water-based paint with mirror effect may further comprise the steps:

[0032] (1) Mix Bayhydrol 2470, CYMEL 385 and co-solvent, and stir at 300r / min for 20min to obtain a mixture;

[0033] (2) Under stirring, slowly add BYK-182 to the mixture obtained in step (1), and continue to disperse at a speed of 500r / min for 20min to prepare component A;

[0034] (3) Mix 10 parts by weight of deionized water, HR-BG / 7800 and BYK-333, and stir at 300r / min for 10min to prepare component B;

[0035] (4) Slowly add component B to component A at a speed of 500r / min, and use DMAE to adjust the mixture to a pH value of 7.0-7.5;

[0036] (5) Use the remaining deionized water as a diluent to dissolve the mixture obtained in step (4), and spray it with air. After the obtained wet film is baked at 140° C. fo...

Embodiment 2

[0038] A kind of water-based paint with mirror effect, by weight, the paint is made of the following components:

[0039]

[0040] The preparation method of the above-mentioned water-based paint with mirror effect may further comprise the steps:

[0041] (1) Mix Bayhydrol RCS 1554, CYMEL 385 and co-solvent, and stir at 300r / min for 20min to obtain a mixture;

[0042] (2) Under stirring, slowly add BYK-182 to the mixture obtained in step (1), and continue to disperse at a speed of 500r / min for 20min to prepare component A;

[0043] (3) Mix 3 parts by weight of deionized water, HR-BG / 7800 and BYK-333, stir at 300r / min for 10min, and prepare component B;

[0044] (4) Slowly add component B to component A at a speed of 500r / min, and use DMAE to adjust the mixture to a pH value of 7.0-7.5;

[0045] (5) Use the remaining deionized water as a diluent to dissolve the mixture obtained in step (4), spray it with air, and bake the obtained wet film at 140° C. for 1 hour to obtain a ...

Embodiment 3

[0050] A kind of water-based paint with mirror effect, by weight, the paint is made of the following components:

[0051] Water-based acrylic resin A (Bayhydrol 2470) 50, water-based amino resin B (CYMEL 385 high imino resin) 10, co-solvent (diethylene glycol butyl ether) 5, defoamer (BYK- 182) 0.1, leveling agent (BYK-333) 0.5, effect pigment (Schlenk Aquamet HR-BG / 7800) 5, amine neutralizer (Deqian DMAE) 0.05, deionized water 10.

[0052] The above-mentioned water-based paint preparation method with mirror effect may further comprise the steps:

[0053] (1) Mix the water-based acrylic resin A, the water-based amino resin B and the cosolvent, and stir at 300r / min for 20min to obtain the mixture;

[0054] (2) Slowly add the defoamer to the mixture obtained in step (1) under stirring, and continue to disperse at a speed of 500r / min for 20min to prepare component A;

[0055] (3) Mix 60-70% deionized water, effect pigment and leveling agent, stir at 300r / min for 10min, and prep...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com