Full-automatic soft-line sectional die-cutting machine and operating method thereof

A fully automatic, die-cutting machine technology, applied in the direction of container manufacturing machinery, box making operations, paper/cardboard containers, etc., can solve the problems of reduced production efficiency, many processing steps, complex structure, etc., to improve production efficiency and processing accuracy High, conducive to the effect of subsequent processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

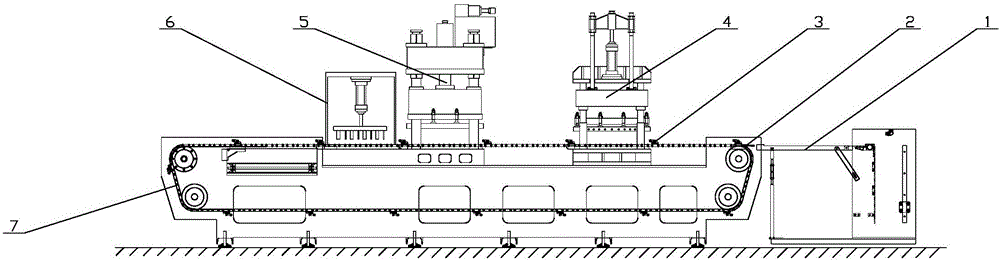

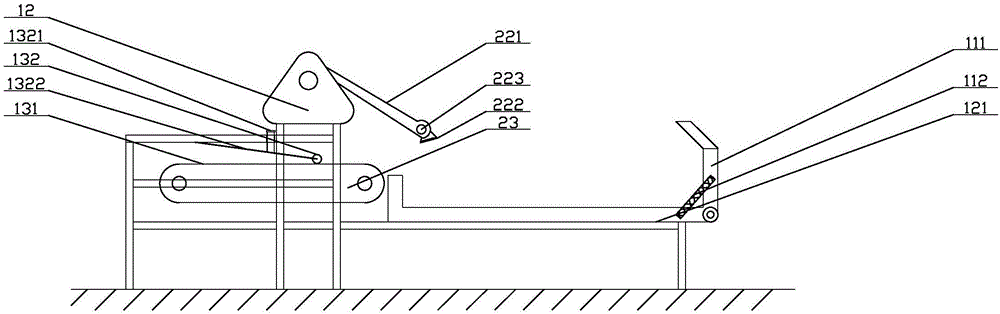

[0087] The present invention as Figure 1-15 As shown, including a frame and a controller, the frame is provided with a closed-loop chain conveyor 7, and the chain conveyor 7 is evenly distributed along the conveying direction with a number of clamping and conveying mechanisms 3. The head end of the frame, the chain The supporting wheel at the head end of the conveyor 7 is the feeding end; a number of scattered processes are combined into an assembly line for production, and the controller is used to control the schedule to achieve automatic production, saving manpower, reducing labor intensity and production costs. The clamping and conveying mechanism clamps the packaging box during the whole process to avoid repeated positioning, improve production efficiency, and improve positioning accuracy.

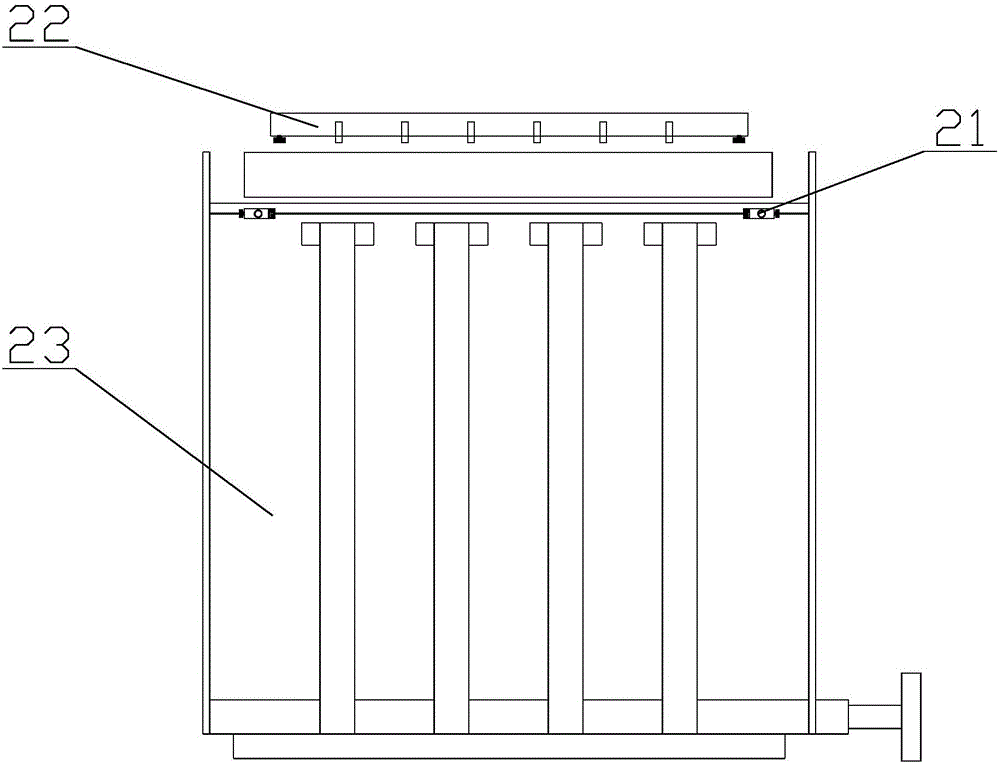

[0088] The middle part of the frame is provided with an indenter 4 and an edge trimmer 5 successively along the conveying direction, and an anti-adhesion mechanism is arranged betwee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com