Amorphous alloy powder and preparation method thereof

An amorphous alloy, iron-based amorphous alloy technology, applied in the direction of magnetic materials, magnetic objects, electrical components, etc., can solve problems such as unfavorable preparation performance magnetic powder core, achieve crystallization transformation and uniform stress release, particle size optimization, The effect of uniform length and width of particles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] This embodiment provides an amorphous alloy powder and a preparation method thereof, and the corresponding preparation method includes the following steps:

[0040] S1. Using a mechanical crusher, the thickness is 18μm, the bandwidth is 10mm, and the composition is Fe 80 Si 9 B 11 The iron-based amorphous alloy thin strips are broken into fragments of 50 mesh to 200 mesh;

[0041] S2. Under a nitrogen protective atmosphere, put the amorphous fragments obtained after the crushing treatment into an atmosphere rotary furnace, and heat-treat at 300°C for 1h. During the heat treatment, control the rotation rate of the atmosphere rotary furnace to 5r / min and the atmosphere pressure 0.1MPa, keep turning the atmosphere rotary furnace, so that the amorphous fragments are evenly heated;

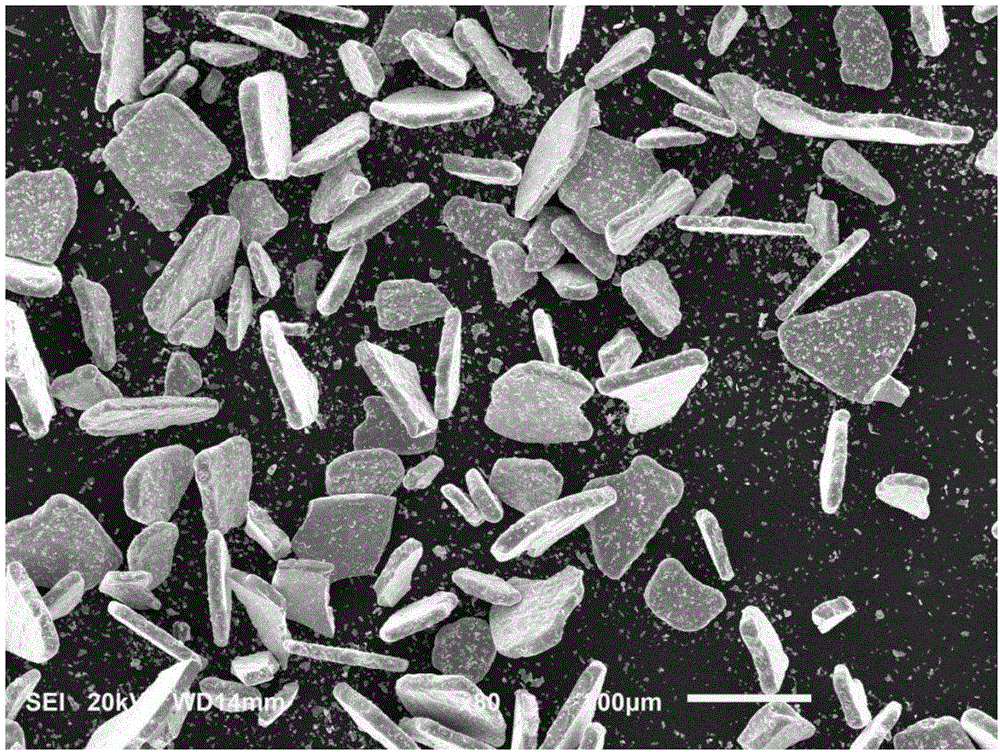

[0042] S3. Put the heat-treated amorphous fragments into the airflow grinder, control the output power of the airflow grinder to 35KW, and grind for 50min to realize the optimization of the p...

Embodiment 2

[0050] This embodiment provides an amorphous alloy powder and a preparation method thereof, and the corresponding preparation method includes the following steps:

[0051] S1. Using a mechanical crusher, the thickness is 20μm, the bandwidth is 20mm, and the composition is Fe 78 Si 9 B 13 The iron-based amorphous alloy thin strips are broken into fragments of 50 mesh to 200 mesh;

[0052] S2. Under a nitrogen protective atmosphere, put the amorphous fragments obtained after the crushing treatment into an atmosphere rotary furnace, and heat-treat at 300°C for 1h. During the heat treatment, control the rotation rate of the atmosphere rotary furnace to 10r / min and the atmosphere pressure 0.2MPa, keep turning the atmosphere rotary furnace, so that the amorphous fragments are evenly heated;

[0053] S3. Put the heat-treated amorphous fragments into the airflow grinder, control the output power of the airflow grinder to 70KW, and grind for 50min to realize the optimization of the ...

Embodiment 3

[0059] This embodiment provides an amorphous alloy powder and a preparation method thereof, and the corresponding preparation method includes the following steps:

[0060] S1. Using a mechanical crusher, the thickness is 25μm, the bandwidth is 30mm, and the composition is Fe 80 Si 9 B 11 The iron-based amorphous alloy thin strips are broken into fragments of 50 mesh to 200 mesh;

[0061] S2. Under a nitrogen protective atmosphere, put the amorphous fragments obtained after the crushing treatment into an atmosphere rotary furnace, and heat-treat at 280°C for 1h. During the heat treatment, control the rotation rate of the atmosphere rotary furnace to 20r / min and the atmosphere pressure 0.3MPa, keep turning the atmosphere rotary furnace, so that the amorphous fragments are evenly heated;

[0062] S3. Put the heat-treated amorphous fragments into the airflow grinder, control the output power of the airflow grinder to 50KW, and grind for 60min to realize the optimization of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com