Natural gas liquefying method and device with light hydrocarbon recovery function

A light hydrocarbon recovery and natural gas technology, applied in liquefaction, refrigeration, liquefaction, solidification, etc., can solve the problems of low separation precision of light hydrocarbons, low LNG recovery rate, and low quality of condensate, and achieve rich product specifications and simple equipment configuration , The effect of simple and cheap operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

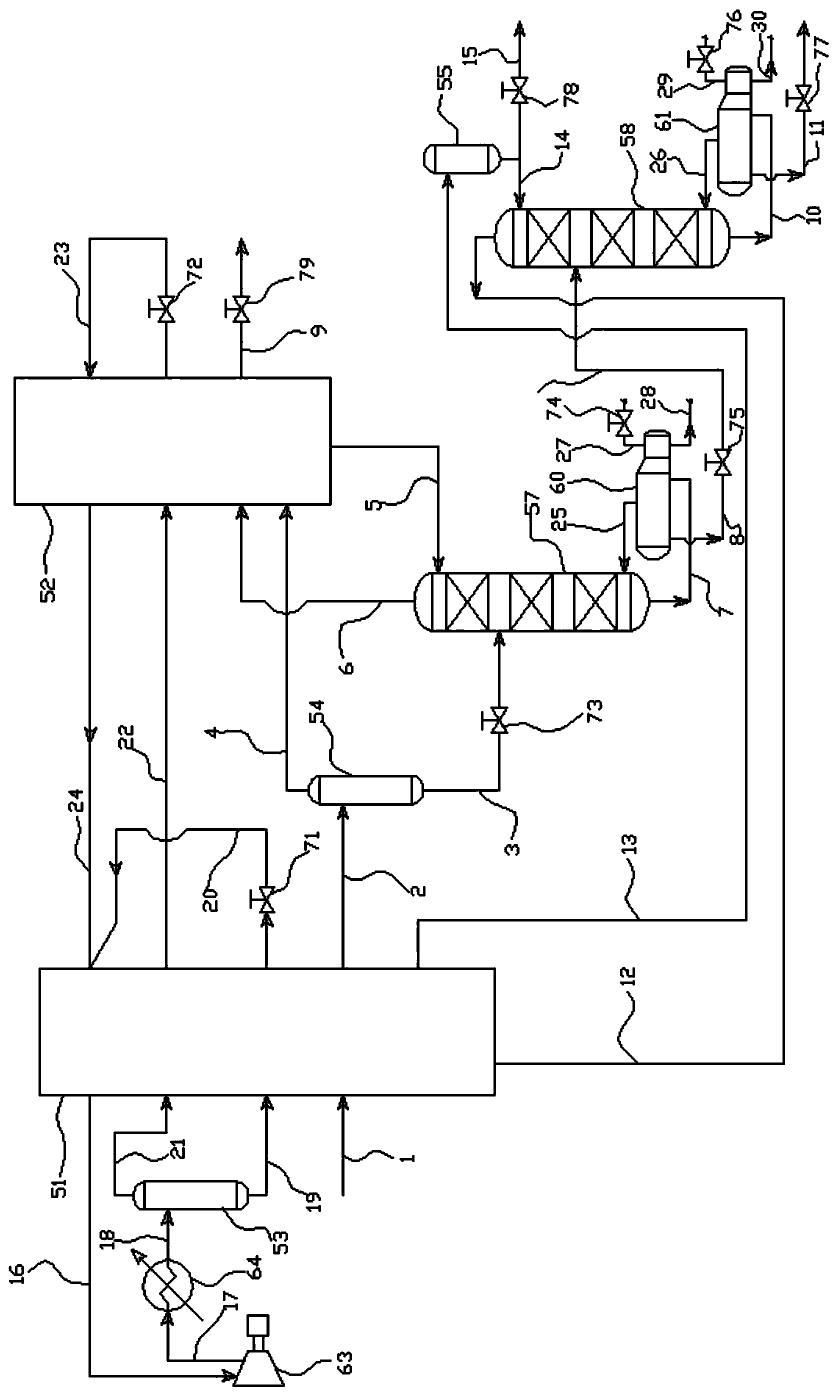

[0046] A natural gas liquefaction method and device thereof with light hydrocarbon recovery, such as figure 1 As shown, it includes a natural gas liquefaction plant with light hydrocarbon recovery. The natural gas liquefaction plant with light hydrocarbon recovery includes a first separator 53, a second separator 54, a refrigerant compressor 63, and a compressor aftercooler 64. Heaters, rectification towers, storage tanks numbered Ⅰ~Ⅴ, control valves numbered a~i and pipelines numbered a~k, m~z and aa~ae, wherein the heat exchanger includes the first heat exchange 51 and the second heat exchanger 52, the rectification column includes the first rectification column 57 with the first bottom reboiler 60, the second bottom reboiler 61 with the first column top separator 55 Second distillation tower 58. In this embodiment, the control valve a71, the control valve b72 and the control valve i79 are all J-T valves.

[0047] The pipeline a1 is connected with the first heat exchanger ...

Embodiment 2

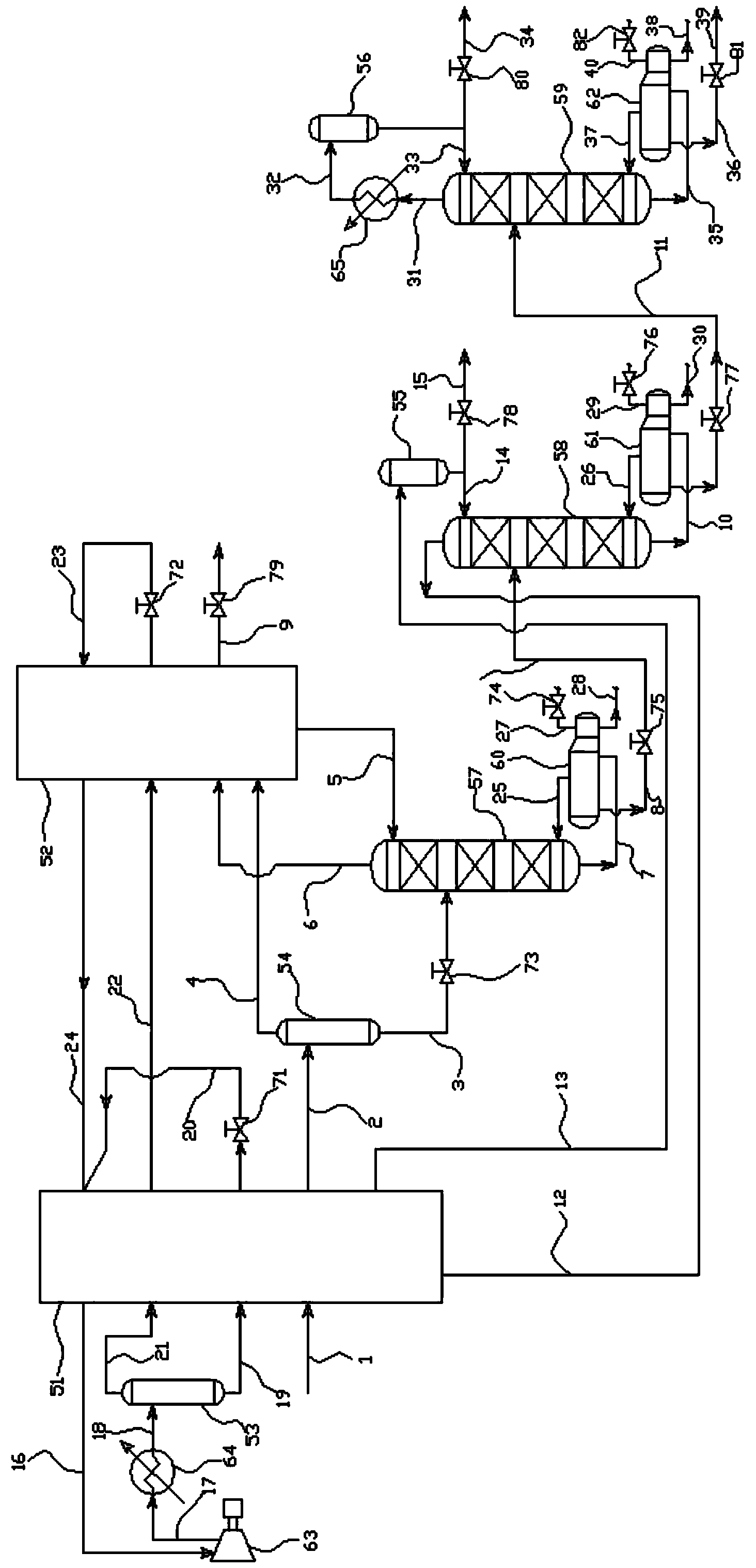

[0077] A natural gas liquefaction method and device thereof with light hydrocarbon recovery, such as figure 2 As shown, it includes a natural gas liquefaction plant with light hydrocarbon recovery. The natural gas liquefaction plant with light hydrocarbon recovery includes a first separator 53, a second separator 54, a refrigerant compressor 63, and a post-compressor separator 64. Heaters, rectification towers, storage tanks numbered Ⅰ~Ⅴ, control valves numbered a~k and m, pipelines numbered a~k, m~z, aa~ak and am~ao, in which heat exchange The device includes a first heat exchanger 51 and a second heat exchanger 52, and the rectification column includes a first rectification column 57 with a first bottom reboiler 60, and a second bottom reboiler 61 with a first column A second rectification column 58 with an overhead separator 55, and a third rectification column 59 with a third bottom reboiler, an overhead condenser 65 and a second overhead separator 56. In this embodiment...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com