Spherical display screen and manufacturing method thereof

A manufacturing method and display technology, applied in the field of display screens, can solve problems such as trapezoidal modules assembled into approximate spherical surfaces, long product design cycles, and reduced display effects, so as to reduce product design cycles, long product design cycles, and reduce design human effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to describe the technical content, structural features, achieved goals and effects of the present invention in detail, the following will be described in detail in conjunction with the embodiments and accompanying drawings.

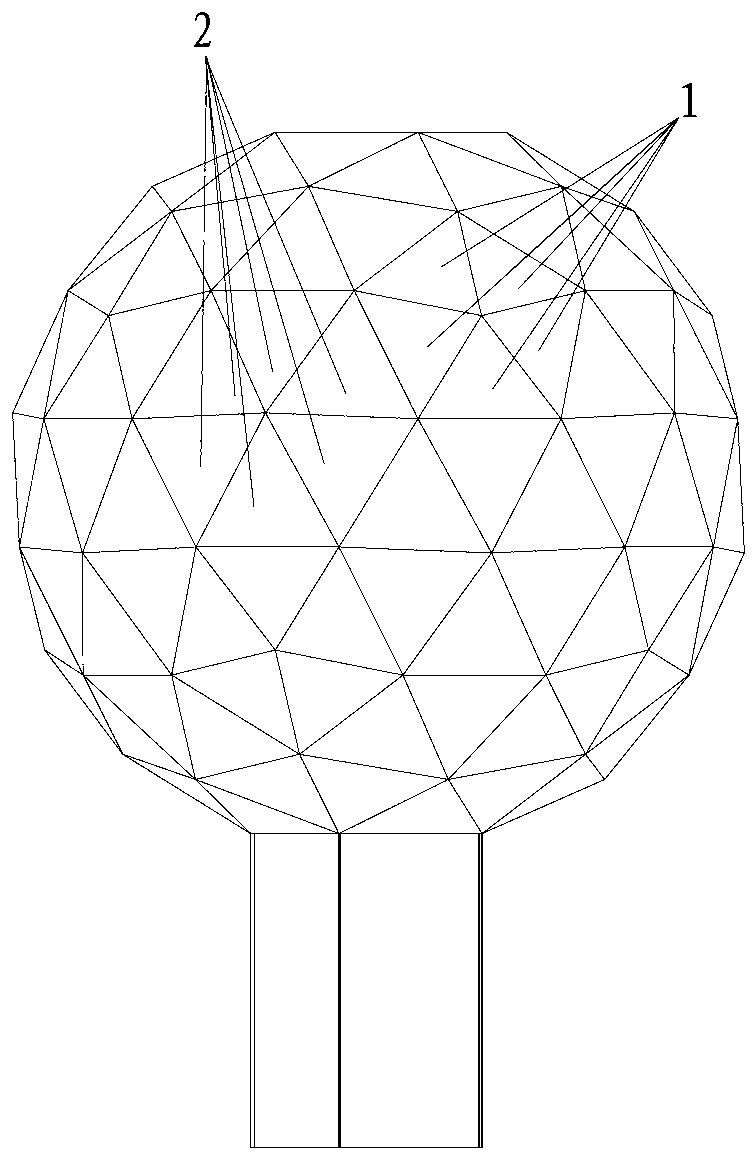

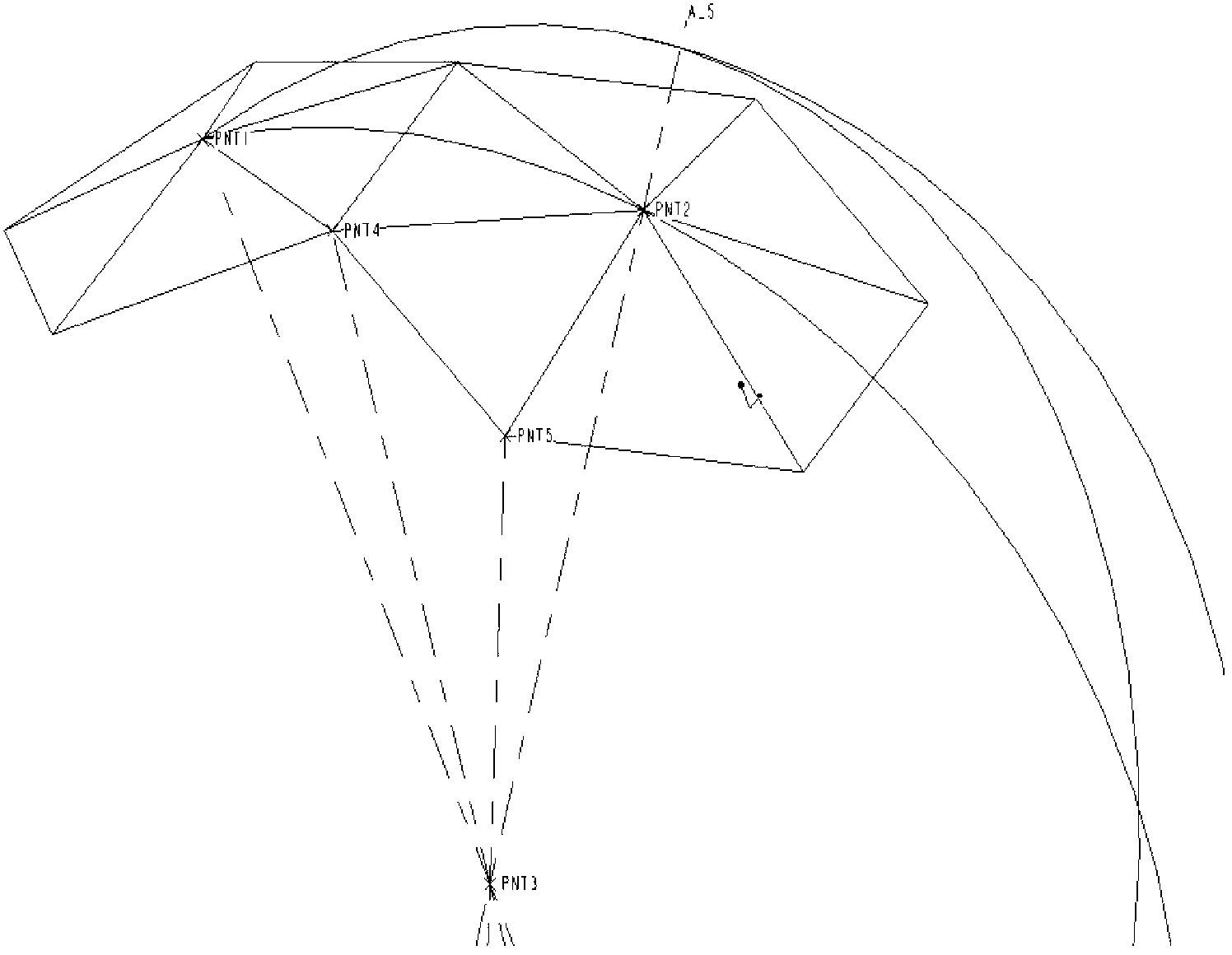

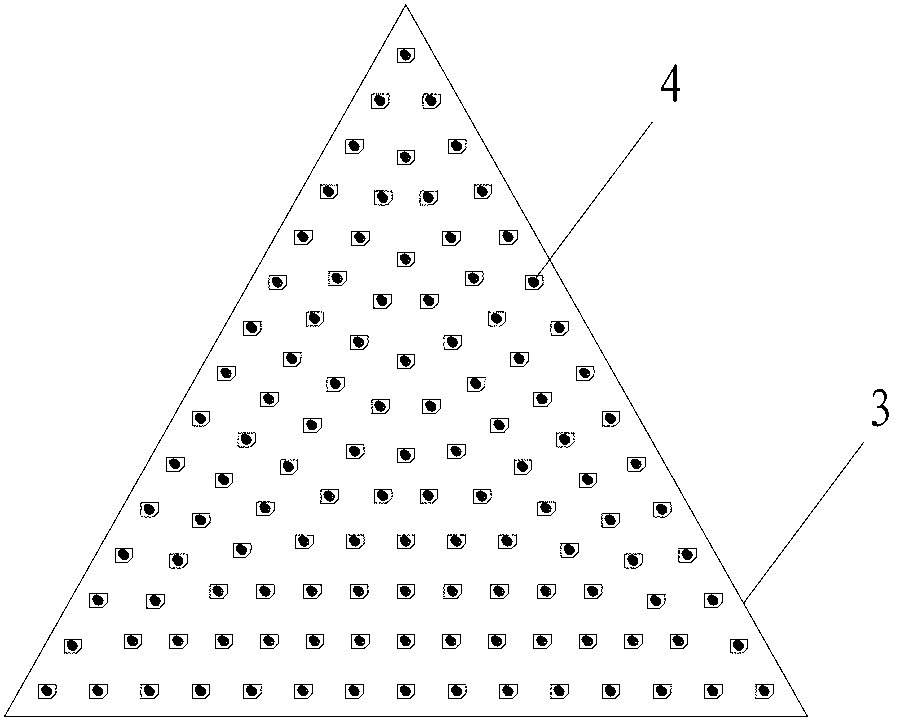

[0022] see Figure 1 to Figure 3 , a manufacturing method of a spherical display in the present embodiment, comprising the steps of:

[0023] S1. According to the Euler's formula in the space, a pentagon with 60 vertices and 90 edges composed of 12 regular pentagons inscribed in the sphere and 20 regular hexagons inscribed in the sphere is obtained. The dodecahedron; where, the specific algorithm is,

[0024] If the number of pentagons, the number of hexagons, the number of faces of a polyhedron, the number of vertices of a polyhedron, and the number of edges of a polyhedron are respectively x, y, F, V, E,

[0025] Then there are: x+y=F, 5x=3y, 3V=2E, V=5x,

[0026] Substituting Euler's formula F+V-E=2 in the space, we get, X=12, y=20, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com