Continuous forming composite structure material and manufacturing method thereof

A composite structure, sawn timber technology, applied in the direction of manufacturing tools, chemical instruments and methods, wood layered products, etc., can solve problems such as slow heat transfer, and achieve the effect of more product specifications, less investment and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

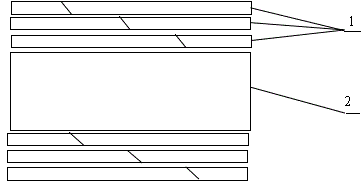

[0029] Composite structural panels with strip laminated lumber (OSL) as the core layer, its structure is as follows figure 1 ,

[0030] Manufacturing methods include the following:

[0031] a. Sorting and finishing of wooden veneers. The moisture content of wooden veneers is ≤9%. The veneers can be milled longitudinally and beveled according to needs, and the tight side and loose side are separated, and glue is applied on both sides according to the requirements. The adhesive is selected Phenolic glue, and a certain amount of insect repellent and about 10% flour can be added. Double-sided glue amount 320g / m 2 ;

[0032] b. Long-strip laminated lumber (OSL) treatment, the long-strip laminated lumber (OSL) is sanded to a fixed thickness to remove the surface cured adhesive layer as a core board, and the small area left by sanding is sanded by a manual sander , and process the longitudinal ends of the two OSLs into a beveled overlapping shape, and apply glue on the beveled su...

Embodiment 2

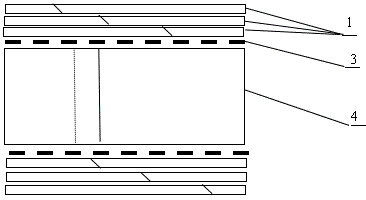

[0041] The structure of the composite structural board with sawn timber as the core layer is as follows: figure 2 ,

[0042] Its manufacturing method includes as follows:

[0043] a. Sorting and finishing of wooden veneers, the moisture content of wooden veneers is ≤10%, the veneers can be milled longitudinally and beveled according to needs, and the tight side and loose side are separated, and glue is applied on both sides as required, and the adhesive is selected Urea-formaldehyde glue, glue amount 300g / m 2 , add 15% flour and other additives in the glue;

[0044] b. Sawn timber treatment. The sawn timber has been dried and planed, with a thickness of 15-35mm, and the end of the board is processed into a finger-joint surface, and the finger-joint surface and sides are coated with urea-formaldehyde glue;

[0045] c. Assembling billets: divide the wooden veneer and sawn timber into three billet sets, and divide the upper and lower veneer layers and the sawn timber core mat...

Embodiment 3

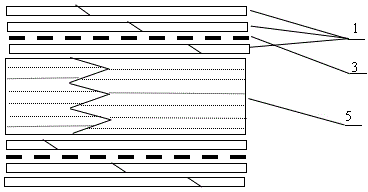

[0053] The structure of the composite structural plate with the edge strip as the core layer is as follows: image 3 ,

[0054] Its manufacturing method includes as follows:

[0055] a. Sorting and finishing of wooden veneers, the moisture content of wooden veneers is ≤10%, the veneers can be milled longitudinally and beveled according to needs, and the tight side and loose side are separated, and glue is applied on both sides as required, and the adhesive is selected Phenolic glue, glue amount 340g / m 2 , add 15% flour in the glue;

[0056] b. For plywood rough sapwood treatment, container bottom plywood is selected. The annual production volume of this plywood in China is about 1 million m3. Add one more saw blade outside the saw blade, and the distance between the two saw blades is about 20-30mm, so as to obtain a slat with a thickness of 28.5mm and a width of 20-30mm. Change the thickness of the side strips to the width of the sides, and process the end faces of the sid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com