Thin film edge material recycling device

A technology of scrap recycling and collection device, which is applied in plastic recycling, recycling technology, metal processing, etc., can solve the problems of factory production inconvenience, low work efficiency, waste of raw materials, etc., achieve diversified specifications and sizes, and improve work efficiency , the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

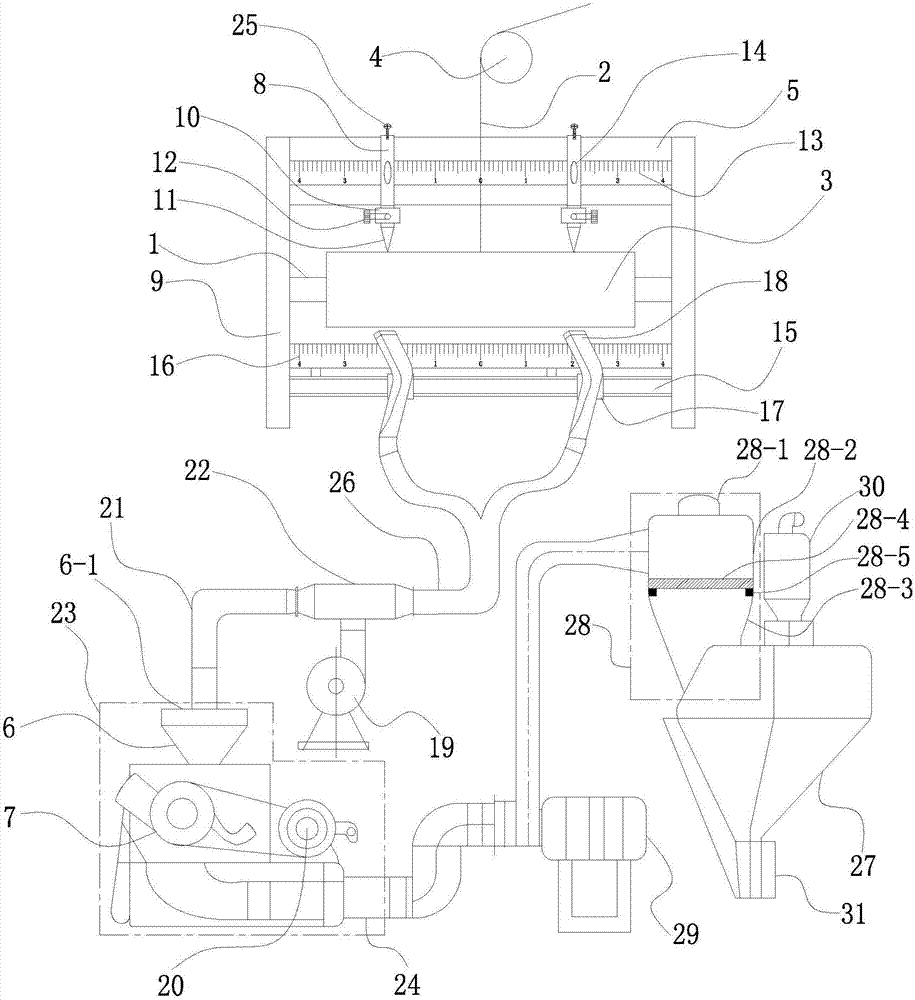

[0021] Example: such as figure 1 As shown, a film scrap recovery device includes a scrap collection device, a frame 9 and a cutting device arranged on the frame 9; the frame 9 is rotatably connected with a winding shaft 1, and the winding shaft 1 is sleeved There is a material receiving roller 3; the cutting device and the edge material collecting device are respectively located at the upper and lower ends of the material receiving roller 3, corresponding to the position of the material receiving roller 3; material breaker device 23, cyclone separator 28 and recovery device; the use of the film edge material recovery device can not only avoid the phenomenon of edge material winding, no need for manual cleaning, save a large amount of production raw materials, and reduce the cost of film products; The production efficiency is greatly improved, the manual operation time is shortened, and the safety factor of production operation is increased.

[0022] The cutting device include...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com