Method of rolled paper cutting and integrated stock optimization in paper factory

A paper roll and inventory technology, applied in instruments, data processing applications, logistics, etc., can solve the problems of low inventory cost, short delayed delivery time, short delivery time for demand, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

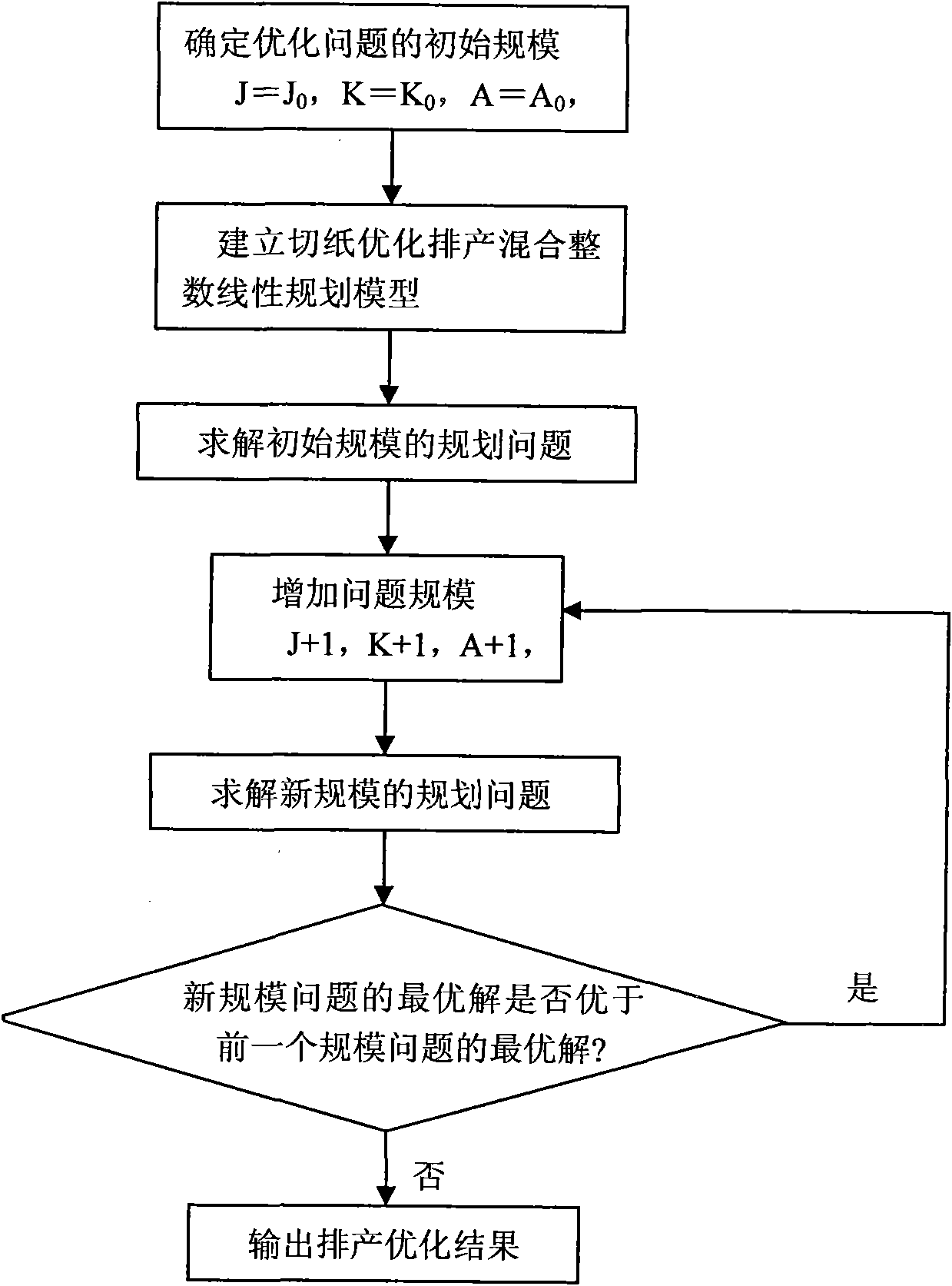

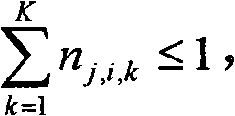

Method used

Image

Examples

Embodiment

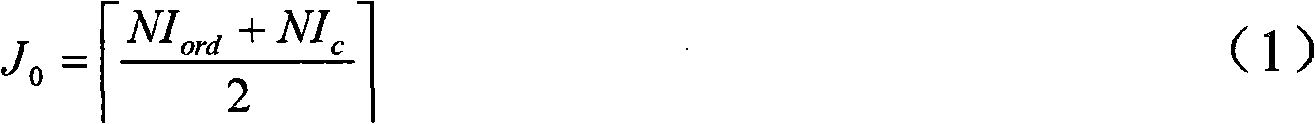

[0080] Take a class of newsprint mills with a variety of products, short lead times, high inventory costs, and large paper machine output as an example. Among them, there is one paper machine and two rewinders. The maximum speed of the paper machine (v m max ) is 2000m / min, the daily vehicle speed (v m ) is 1600m / min, the maximum width of the paper roll produced (BJ j max ) is 10.06m. The transfer time of the large paper roll from the paper machine to the rewinder (T t ) is 3min. The maximum speed of the two rewinders (v w max ) is 2500m / min, the daily vehicle speed (v w ) is 2000m / min, the maximum number of copies that can be cut into large paper rolls (NJ j max ) is 15 copies (a total of 16 cutters), and the width of the edge of the paper must be cut off at least on both sides of the large paper roll (Δ j min ) is 0.03m, the width that can only be cut at most (Δ j max ) is 0.25m. Therefore, the effective width of the jumbo roll, that is, the width of each com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com