Bearing end cover production scheduling optimization method based on heuristic algorithm

A heuristic algorithm, bearing end cover technology, applied in computing, manufacturing computing systems, instruments, etc., to achieve the effect of improving utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

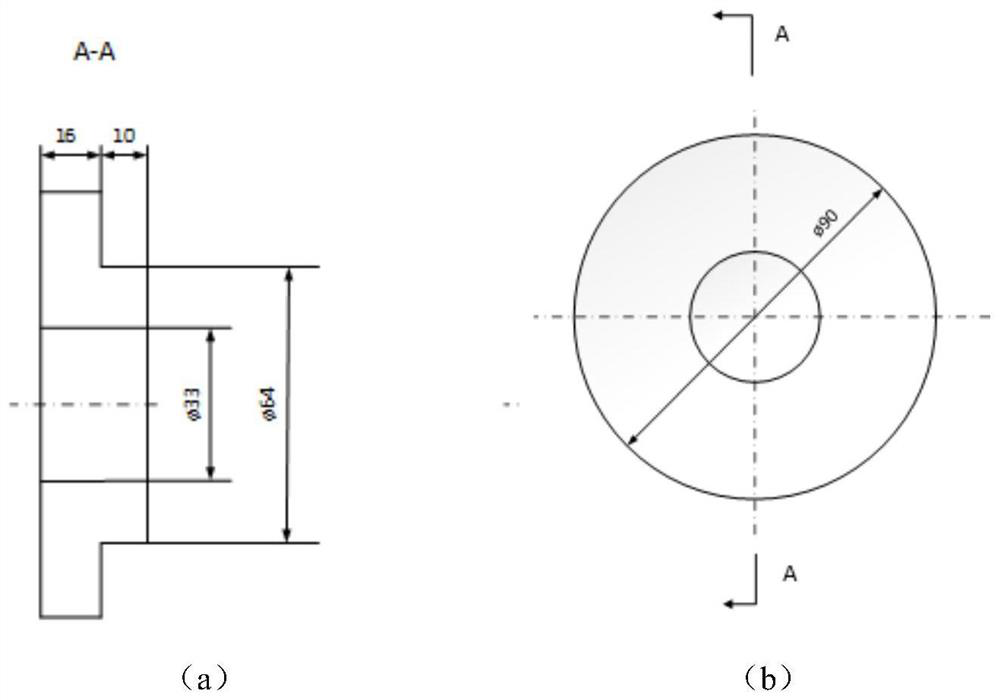

[0045] In this embodiment, as figure 1 The bearing end cover shown is taken as an example, and the production scheduling and production scheduling of the bearing end cover is optimized by using the heuristic algorithm-based production scheduling optimization method of the bearing end cover of the present invention.

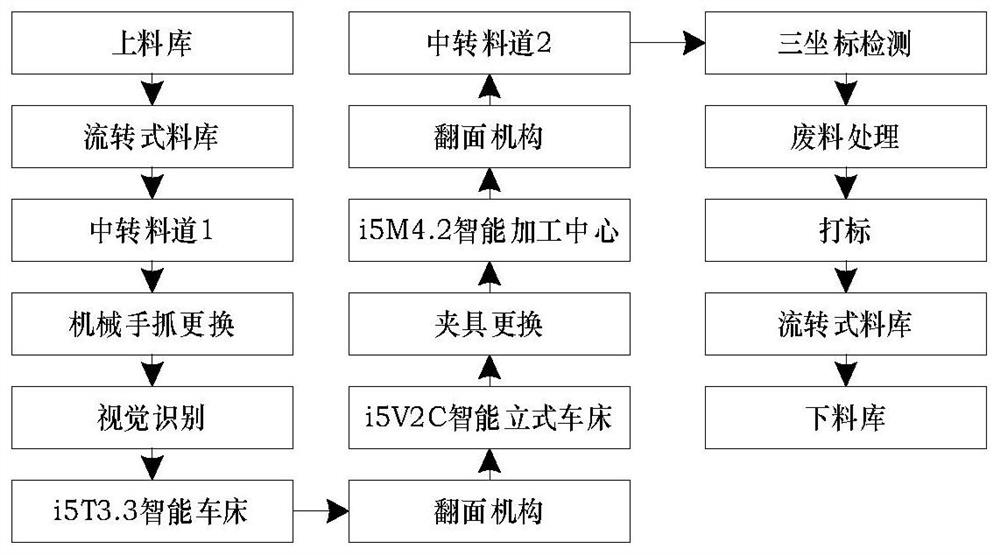

[0046] In this embodiment, the specific wiring method and required equipment of the bearing end cover are shown in Table 1 below.

[0047] Table 1 Statistical table of bearing cover i5 machine tool form information

[0048]

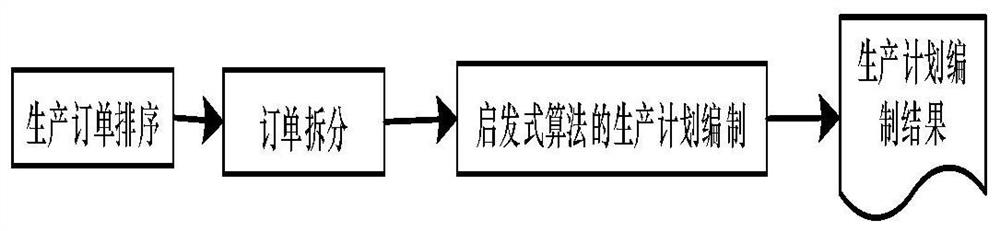

[0049] The method of the invention takes the bearing end cover production line as the research object, and carries out the preparat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com