Method and device for controlling oil production and fluid production

A control method and control device technology, which is applied in the directions of measurement, fluid extraction, earthwork drilling, etc., can solve the problems that oil and water wells cannot maintain high-efficiency and stable production for a long time, so as to improve development efficiency, avoid damage and high-efficiency production process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

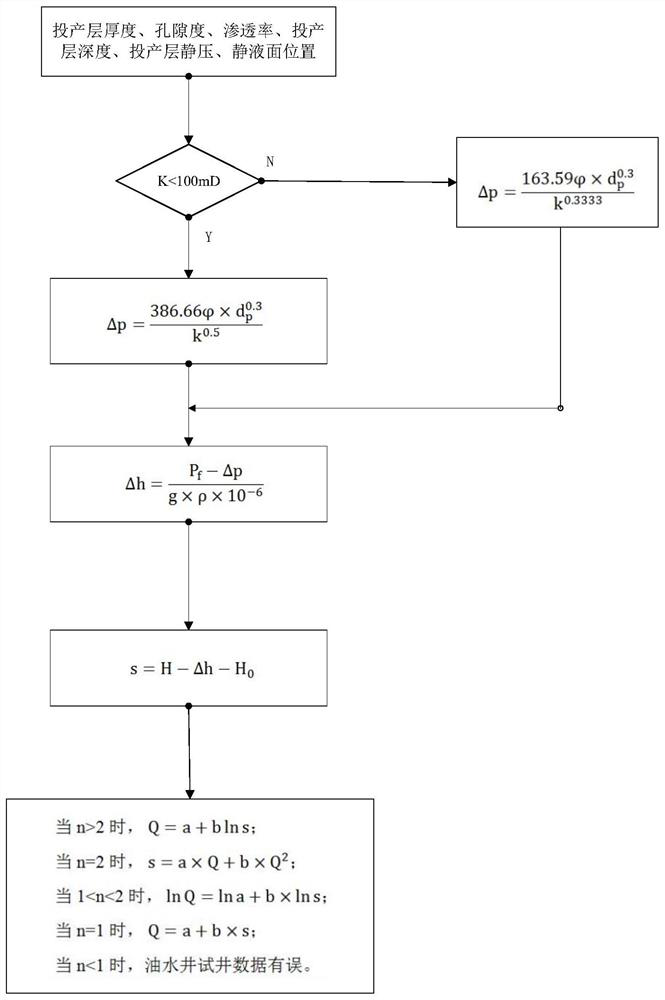

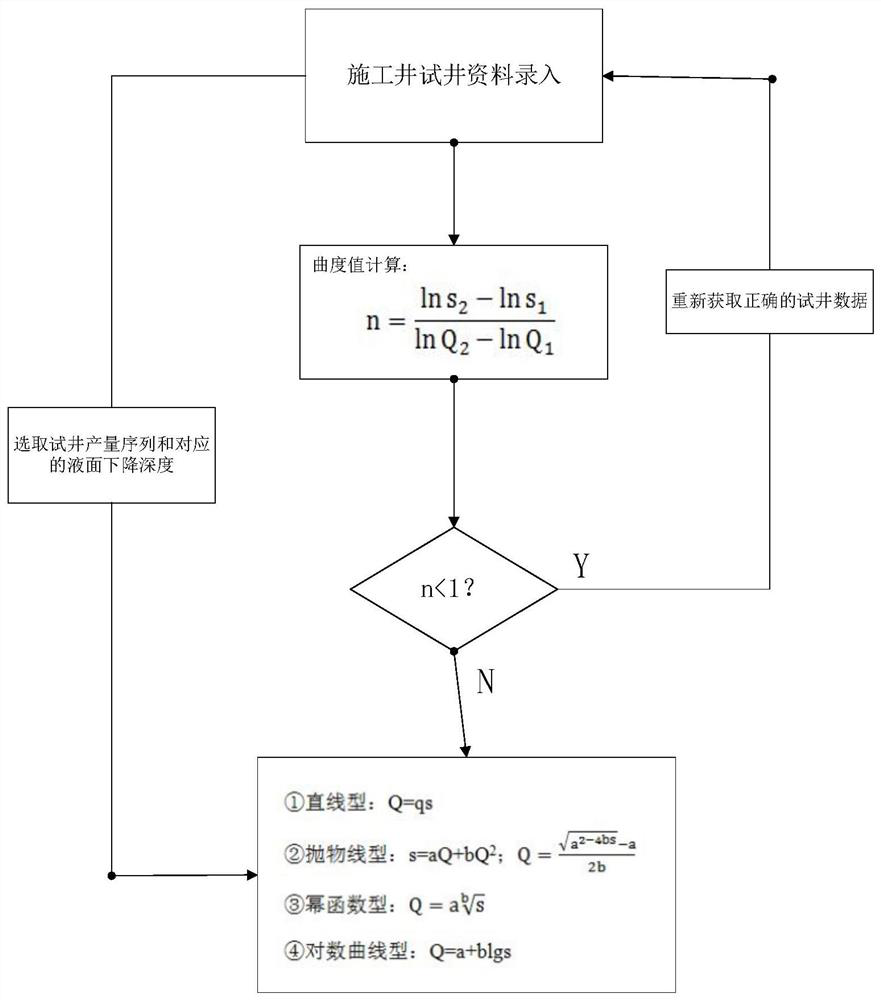

[0035] Under the condition of sufficient liquid supply, the greater the drop in the dynamic liquid level of the oil-water well, the higher the production; but after considering the physical properties and pressure of the formation, the production has an inflection point, beyond this inflection point, the rock cemented skeleton breaks, the formation produces sand, and the production is low. It will increase again, but become smaller; continue to enlarge the production, due to the excessive drop of the liquid level, the negative pressure at the bottom of the well will increase, and the light one will lead to the destruction of the interlayer, causing interlayer channeling, and the production will drop; the severe one will cause the oil-water well casing Tube damaged and scrapped. The bottom hole negative pressure is generally used for perforation or plugging removal. The basic principle is to use the pressure of the wellbore fluid column to be lower than the reservoir pressure, s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com