Isothermal-isobaric multipurpose thermal tempering equipment for ultra-thin glass

An ultra-thin glass, multi-purpose technology, used in glass tempering, glass manufacturing equipment, glass forming, etc., can solve the problems of unstable temperature of heating furnace, uneven cooling, uneven heating, etc., to increase production flexibility , Reduce the amount of glass deformation and ensure the effect of production quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

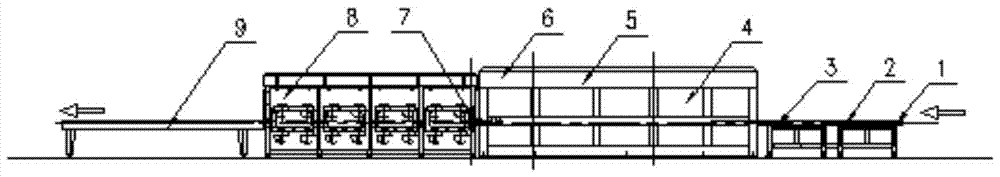

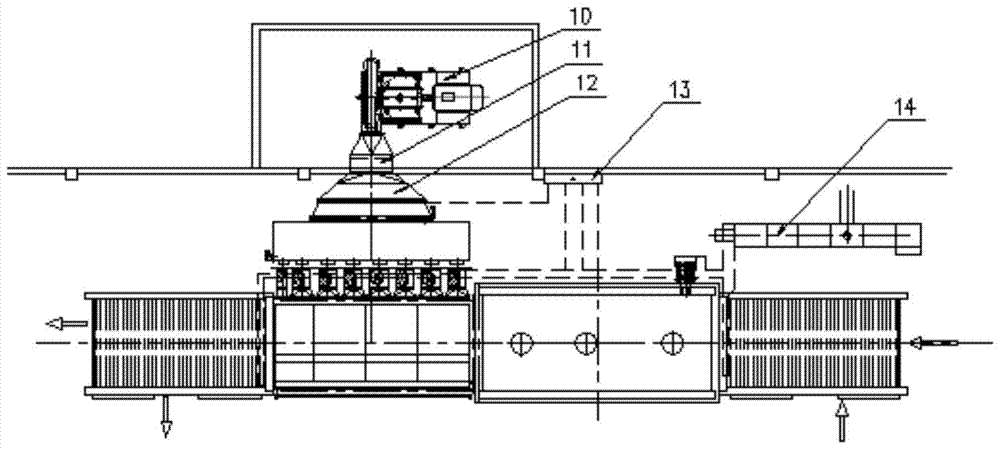

[0031] Example: see figure 1 and figure 2 , in the figure, 1-feeding section, 2-pneumatic workbench, 3-into the furnace waiting area, 4-glass preheating area, 5-glass softening area, 6-glass stabilization area, 7-glass shaping area, 8- Glass tempering area, 9-Unloading table, 10-Fan, 11-Cooling medium constant temperature system, 12-Fan pipeline system, 13-Pneumatic pipeline system, 14-Electrical control system.

[0032] Physical tempering equipment for ultra-thin glass below 2.5mm includes loading table, heating furnace, tempering section, unloading table 9, fan 10, fan piping system 12, electrical control system 14, air pressure piping system 13, cooling medium constant temperature system 11 . Among them, the loading table, heating furnace, tempering section, and unloading table 9 are installed in sequence, and the fan 10 is connected to the tempering section through the fan pipeline system 12 to continuously and evenly supply air to the tempering section. For the effect...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com