Quick heating device for high-temperature SHPB dynamic impact experiment

A shock test and rapid heating technology, applied in the preparation of test samples, etc., can solve the problems of ignoring the difference of stress wave propagation, affecting the accuracy of experimental data, difficult static docking and synchronization, etc., and achieve convenient heating of test pieces , Various specifications, easy to operate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to make the object, technical scheme and advantages of the present invention clearer, the present invention will be described in further detail below in conjunction with accompanying drawing:

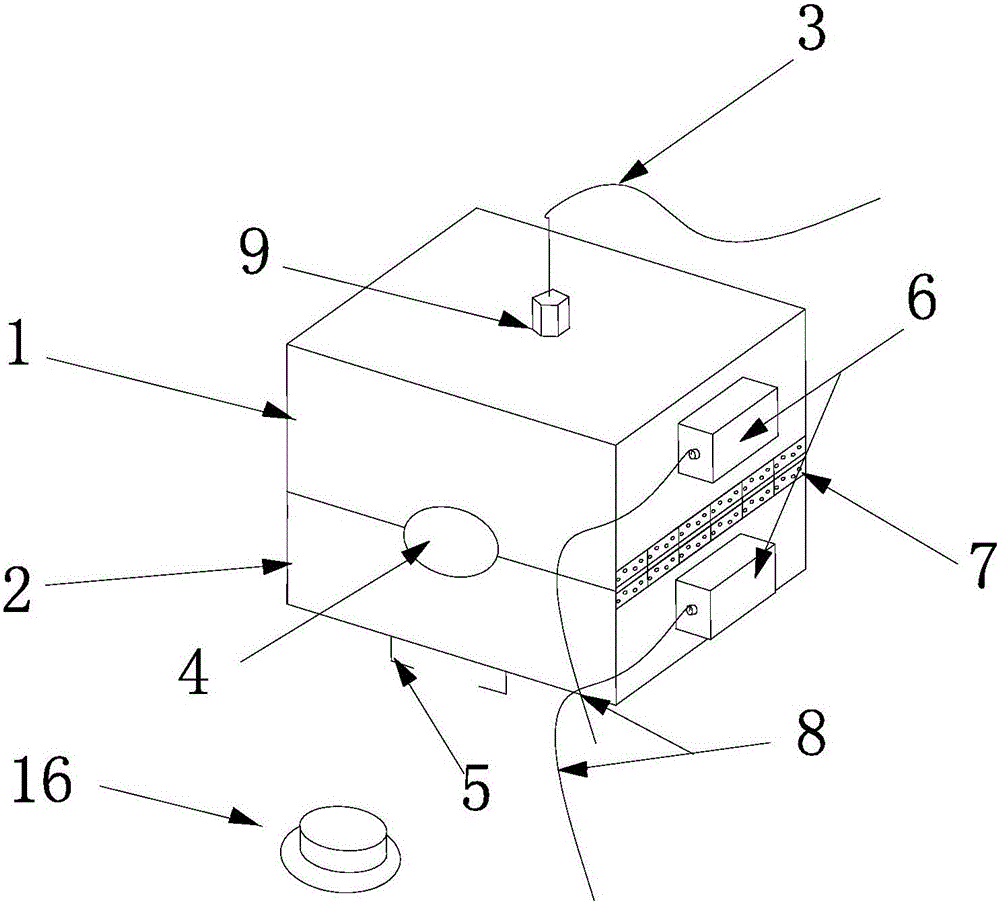

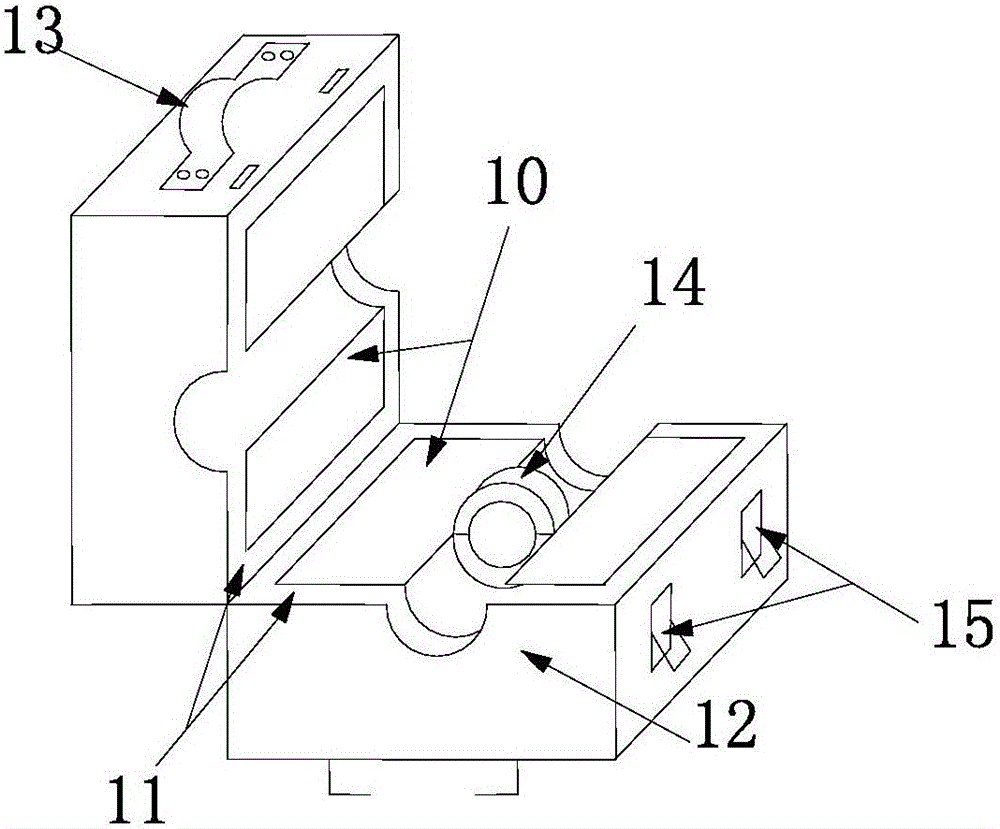

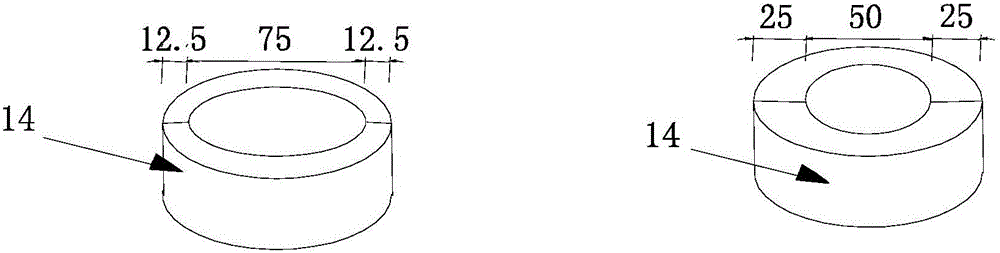

[0023] A rapid heating device for high-temperature SHPB dynamic impact experiments, including an upper box (1), a lower box (2), a temperature sensor (3), a heating channel (4), a guide rail (5), an electrothermal conversion device ( 6), hinge (7), wire (8), temperature measuring hole (9), heating tile (10), insulation cotton (11), outer wall (12), handle (13), ring (14), tight Firmware (15), heat preservation board (16), described upper box body (1) and lower box body are connected by hinge (7), described upper box body (1) and lower box body (2) are engraved with two a semicircle and can be combined into a full circle heating channel (4), the upper box (1) is connected with a temperature sensor (3), and the lower box (2) is connected with a guide rail (5) , the upper ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com