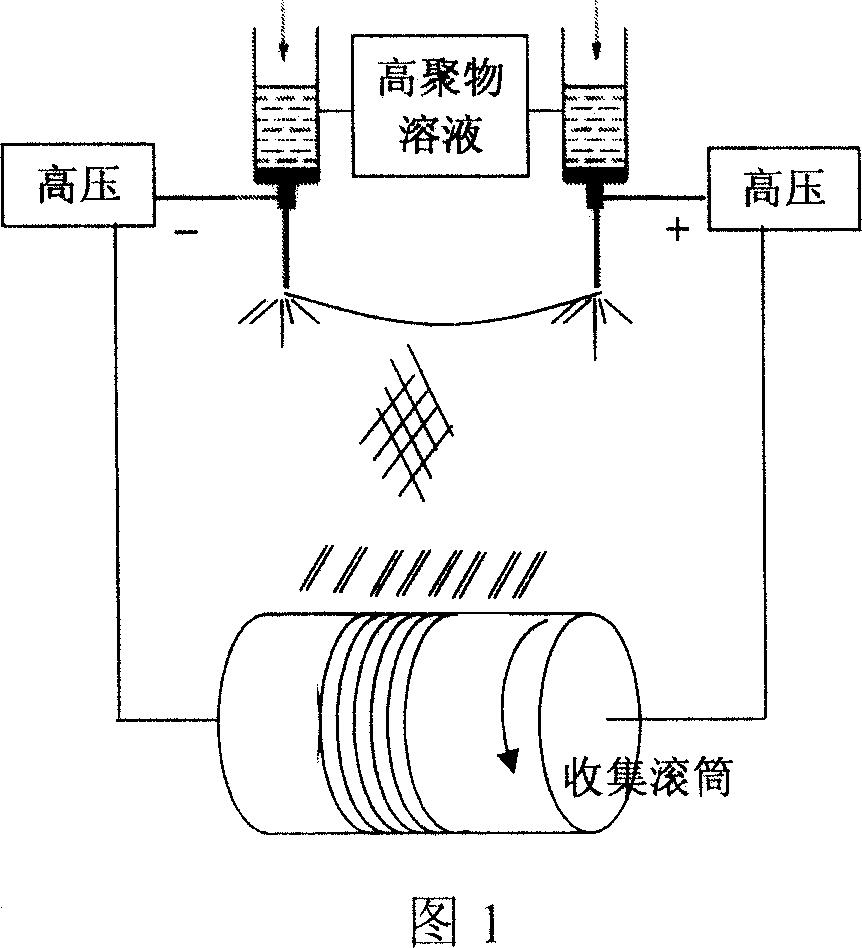

Complex type electrostatic spinning method with positive and negative electrodes in same electric field, and application

A technology of electrospinning, positive and negative electrodes, applied in the field of spinning, can solve the problems that the fiber diameter can only be controlled to the same size and the spinning speed is slow, and achieve the effect of increasing porosity and increasing Young's modulus.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] 100 parts of chloroform, 16 parts of polylactic acid (PLA), solution conductivity 0.002us / cm. Positive and negative voltage control 8.5kv, receiving distance 20 cm.

Embodiment 2

[0022] N, N-diformamide (DMF) 100 parts, polylactic acid (PLA) 12 parts, solution conductivity 14.50us / cm. The voltage control is 6.5kv, the receiving distance is 20 cm, the room temperature condition, and the traction rate is 100 rpm.

Embodiment 3

[0024] 100 parts of chloroform, 20 parts of PHBV, the conductivity of the solution is 0.002us / cm. The voltage control is 7.5kv, the receiving distance is 25cm, and the room temperature condition.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com