Multilayer electret nano-fiber filtering material and preparation method thereof

A nanofiber and filter material technology, applied in the fields of filtration and separation, separation methods, membrane filters, etc., can solve the problems of inability to meet actual use requirements, attenuation of electret performance, reduction of production efficiency, etc., to improve charge storage capacity and charge. Stability, enhanced electrostatic effect, improved liquid output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

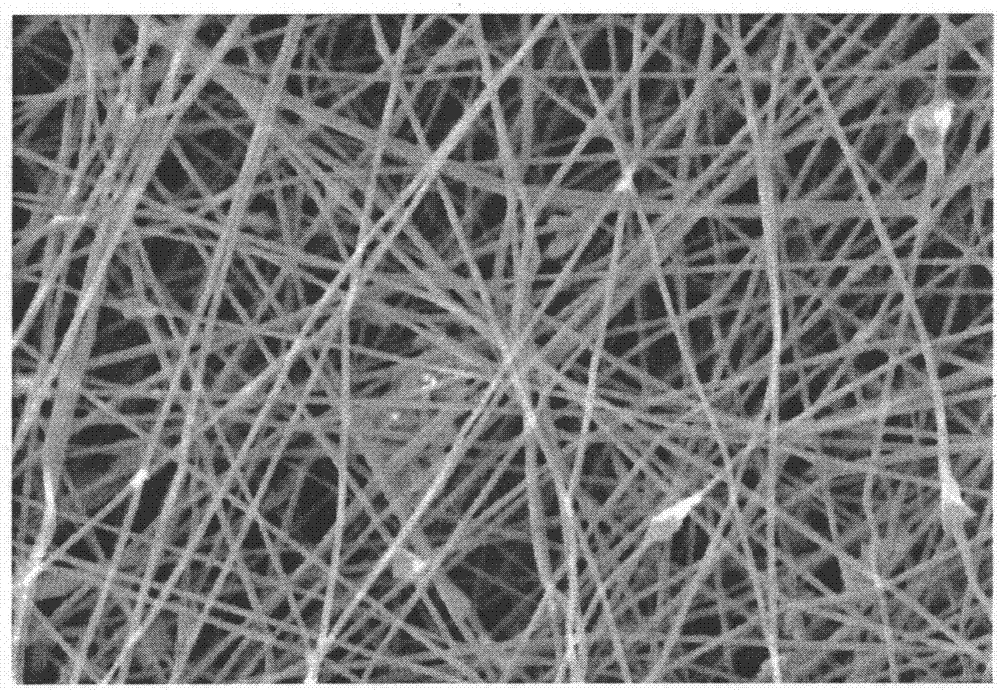

Image

Examples

Embodiment 1

[0026] A multilayer electret nanofiber filter material and a preparation method thereof, the preparation method comprising the following steps:

[0027] 1) Preparation of spinning solution: uniformly disperse hydroxyapatite (addition amount 0.5wt%, particle size 0.05μm) in formic acid to form a dispersion solution, and use ultrasonic disperser (ultrasonic frequency 40kHz, ultrasonic temperature 80 ℃) to ultrasonically stir After 20 minutes, nylon 6 (with a weight average molecular weight of 50,000) was added to the dispersion, and after sealing, it was continuously stirred for 15 hours with a magnetic stirring device, and finally a stable and uniform polymer spinning solution with a concentration of 10 wt% was prepared;

[0028] 2) Electrospinning: the prepared polymer spinning solution is sucked into the spinning module through the liquid supply device, and the combined needle for electrospinning is used to realize the spinning polymer solution to be stretched at the tip of th...

Embodiment 2

[0033] A multilayer electret nanofiber filter material and a preparation method thereof, the preparation method comprising the following steps:

[0034] 1) Spinning solution preparation: hydroxyapatite (addition amount 0.5wt%, particle size 0.1 μm) is uniformly dispersed in N,N-dimethylacetamide to form a dispersion liquid, and an ultrasonic disperser (ultrasonic frequency 40kHz , ultrasonic temperature 70° C.) after ultrasonic stirring for 30 min, polyurethane (weight average molecular weight: 80,000) was added to the dispersion, and after sealing, it was continuously stirred for 8 hours with a magnetic stirring device, and finally a stable and uniform concentration of 15 wt % was prepared. polymer spinning solution;

[0035]2) Electrospinning: the prepared polymer spinning solution is sucked into the spinning module through the liquid supply device, and the combined needle for electrospinning is used to realize the spinning polymer solution to be stretched at the tip of the ...

Embodiment 3

[0040] A multilayer electret nanofiber filter material and a preparation method thereof, the preparation method comprising the following steps:

[0041] 1) Preparation of spinning solution: uniformly disperse polytetrafluoroethylene (0.05wt% added, particle size 0.2μm) in N,N-dimethylformamide to form a dispersion, and use an ultrasonic disperser (ultrasonic frequency 35kHz , ultrasonic temperature 50°C) after ultrasonic stirring for 40 minutes, polyvinylidene fluoride (weight average molecular weight: 320,000) was added to the dispersion, and after sealing, it was continuously stirred for 9 hours with a magnetic stirring device, and finally a stable and uniform concentration of 18wt% polymer spinning solution;

[0042] 2) Electrospinning: the prepared polymer spinning solution is sucked into the spinning module through the liquid supply device, and the combined needle for electrospinning is used to realize the spinning polymer solution to be stretched at the tip of the solid ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| Basis weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com