A kind of preparation method of high-performance polyacrylonitrile-based carbon fiber precursor

A polyacrylonitrile-based carbon fiber, polyacrylonitrile spinning technology, applied in the direction of rayon manufacturing, fiber chemical characteristics, single-component synthetic polymer rayon, etc., can solve the unseen preparation method of polyacrylonitrile-based carbon fiber precursor Related reports and other issues, to achieve the effect of increasing the degree of orientation, improving production efficiency, and increasing spinning speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

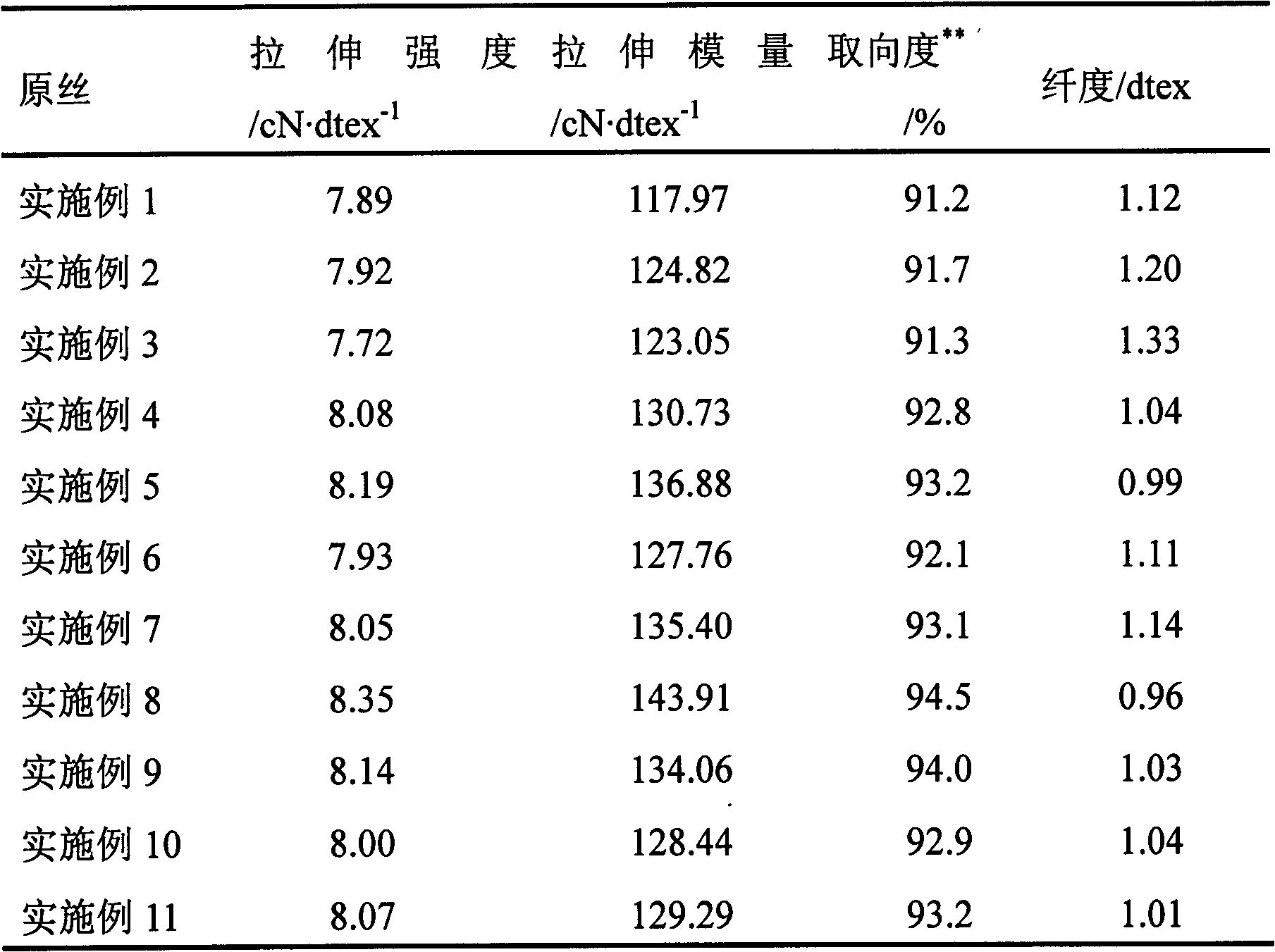

Examples

Embodiment 1

[0032] A polyacrylonitrile resin with a weight-average molecular weight of 2,730,000 and a molecular weight distribution of 2.81 was added into dimethylformamide, and stirred at 50°C for 2 hours to obtain a dilute ultra-high molecular weight polyacrylonitrile solution with a mass concentration of 0.5%. A polyacrylonitrile resin with a weight average molecular weight of 105,000 and a molecular weight distribution of 2.33 was dissolved in the dilute polyacrylonitrile solution, stirred at 55°C for 2 hours, and then stirred at 80°C for 5 hours to obtain a spinning dope. The spinning stock solution is extruded through the spinneret, and after passing through a 2cm air section, it enters a dimethylformamide / water coagulation bath with a temperature of 25°C and a mass concentration of dimethylformamide of 40% for coagulation and formation. The ratio of the winding speed of a winding roller to the stock solution extrusion speed is 18. The as-spun filaments were washed and stretched 1....

Embodiment 2

[0034] A polyacrylonitrile resin with a weight average molecular weight of 21100000 and a molecular weight distribution of 2.55 was added into dimethylformamide, and stirred at 55°C for 2 hours to obtain a dilute ultrahigh molecular weight polyacrylonitrile solution with a mass concentration of 1%. A polyacrylonitrile resin with a weight average molecular weight of 85,000 and a molecular weight distribution of 2.50 was dissolved in the dilute polyacrylonitrile solution, stirred at 60°C for 2 hours, and then stirred at 80°C for 5 hours to obtain a spinning dope. The spinning stock solution is extruded through the spinneret, and after passing through a 2cm air section, it enters a dimethylformamide / water coagulation bath with a temperature of 25°C and a mass concentration of dimethylformamide of 40% for coagulation and formation. The ratio of the winding speed of a winding roller to the extrusion speed of the stock solution is 15. The as-spun filaments were washed and stretched ...

Embodiment 3

[0036]A polyacrylonitrile resin with a weight average molecular weight of 1,690,000 and a molecular weight distribution of 3.06 was added to dimethyl sulfoxide, and stirred at 50° C. for 2 hours to obtain a dilute solution of ultrahigh molecular weight polyacrylonitrile with a mass concentration of 1%. A polyacrylonitrile resin with a weight average molecular weight of 143,000 and a molecular weight distribution of 2.61 was dissolved in the dilute polyacrylonitrile solution, stirred at 55°C for 3 hours, and then stirred at 75°C for 5 hours to obtain a spinning dope. The spinning stock solution is extruded through the spinneret, and after passing through a 2cm air section, it enters a dimethyl sulfoxide / water coagulation bath with a temperature of 25°C and a mass concentration of dimethyl sulfoxide of 50% for coagulation and formation. The ratio of the winding speed of a winding roller to the extrusion speed of the stock solution is 12. The as-spun filaments were washed and str...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The molecular weight distribution | aaaaa | aaaaa |

| The molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com