Cutting board slotting equipment

A technology of grooving equipment and cutting board, which is applied in the directions of grooving machine, mortising machine, fixed drilling machine, etc. Manpower saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

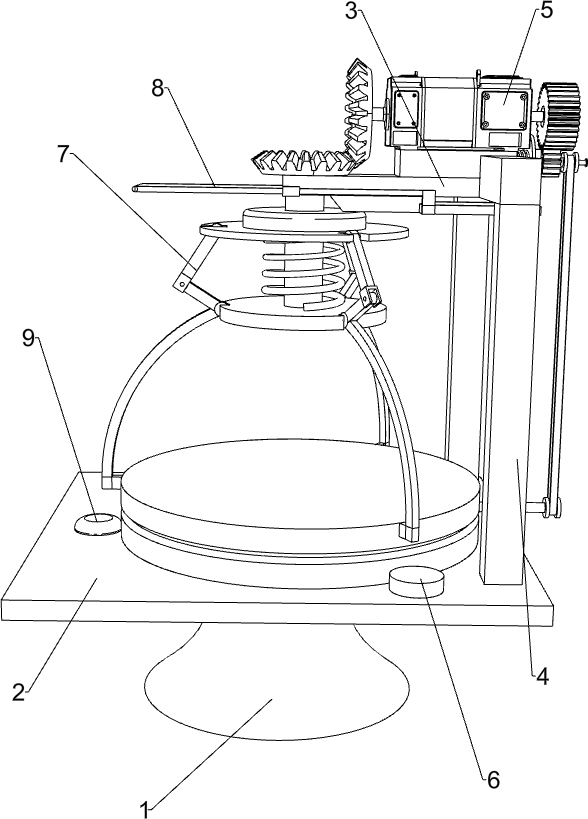

[0025] first implementation

[0026] A cutting board grooving device such as Figure 1-2 As shown, it includes outrigger 1, workbench 2, horizontal plate 3 and support 4, the top of outrigger 1 is connected with workbench 2, the top right side of workbench 2 is connected with support 4, and the top of support 4 is connected with horizontal plate 3, It also includes a slotting assembly 5 and a fixed positioning column 6, the slotting assembly 5 is arranged between the horizontal plate 3 and the bracket 4, and the front and rear sides of the top of the workbench 2 are connected with the fixed positioning column 6.

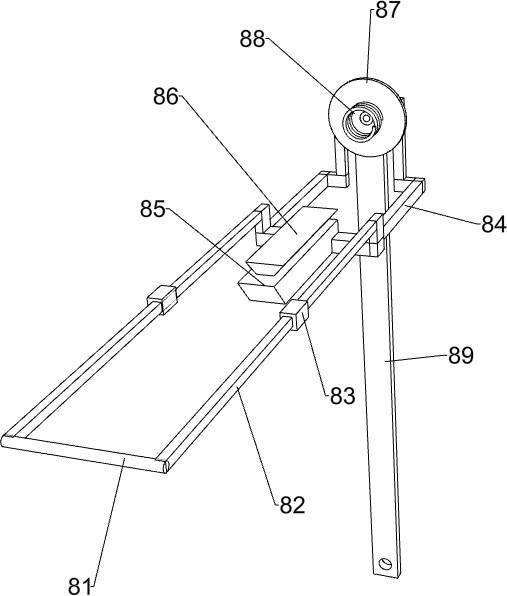

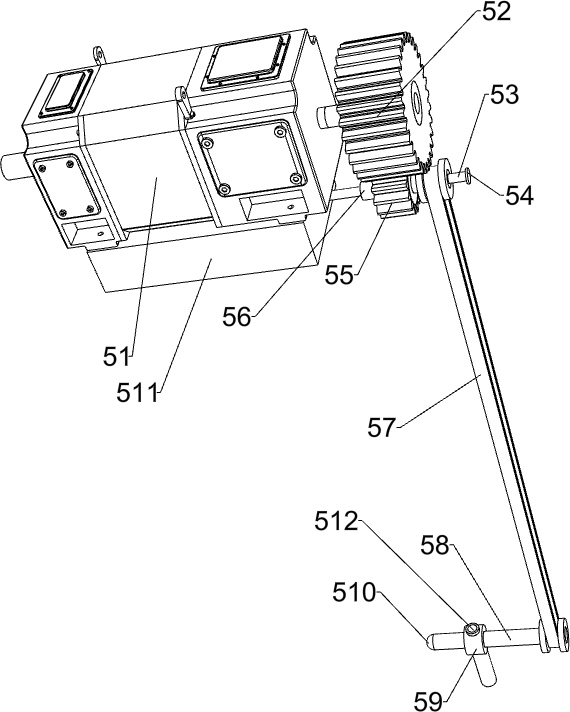

[0027] The slotting assembly 5 includes a motor 51, a first gear 52, a first shaft 53, a positioning plate 54, a second gear 55, an axle sleeve 56, a belt 57, a second shaft 58, a first sliding sleeve 59, a drill bit 510, an installation Sea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com