A kind of grip installation groove slotting device of chopping board

A technology for installing grooves and handles, applied in metal processing, etc., can solve the problems of low work efficiency, labor-consuming, heavy electric drill, etc., and achieve the effect of improving work efficiency, simple operation and ensuring safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below with reference to the accompanying drawings and embodiments.

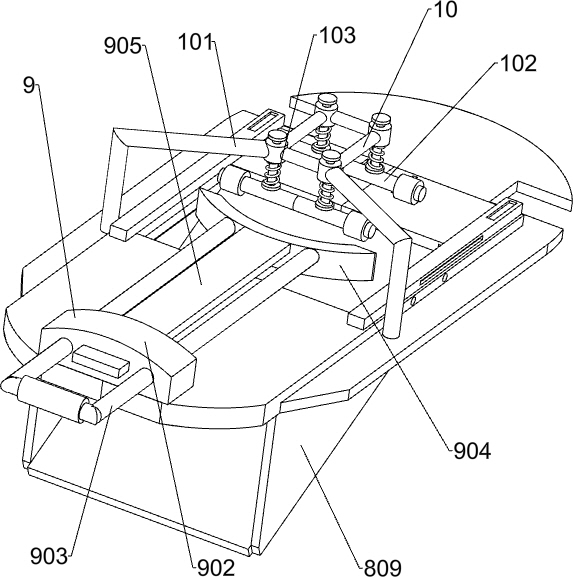

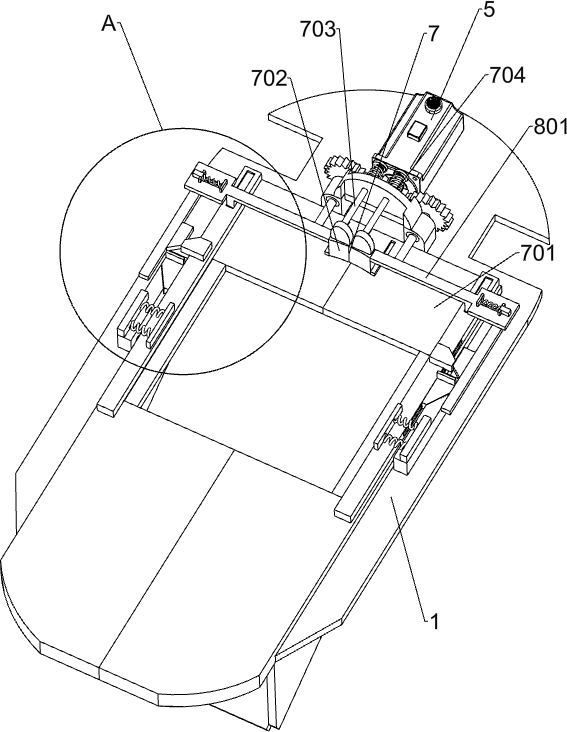

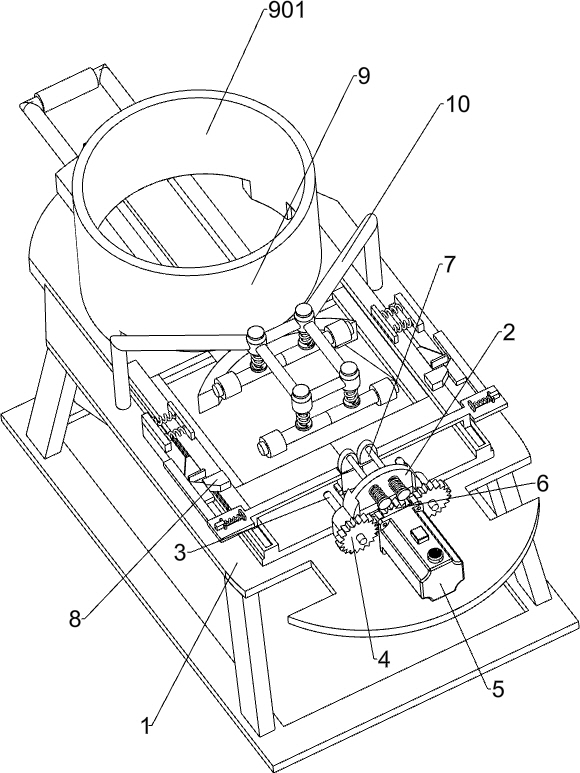

[0023] first embodiment

[0024] A grip installation slotting device for a cutting board, such as Figure 1-3 As shown, it includes a mounting plate 1, a shaft seat 2, a drill rod 3, a side gear 4, a motor 5 and a driving gear 6. The front side of the top of the mounting plate 1 is connected with a shaft seat 2, and the left and right sides of the shaft seat 2 are connected in a rotary manner. There is a drill rod 3, a side gear 4 is connected to the drill rod 3, a motor 5 is installed on the front side of the top of the mounting plate 1, and a driving gear 6 is connected to the output shaft of the motor 5. The two sides of the driving gear 6 are respectively connected with the side gears 4 on both sides. It also includes a guide device 7 and a discharge device 8. A guide device 7 is provided between the mounting plate 1 and the shaft seat 2, and a disch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com