Cutting board grooving device

A technology for cutting grooves and chopping boards, which is applied to clamping devices, feeding devices, slotting machines, etc., can solve the problems of long time consumption, low work efficiency, and manpower consumption, so as to save manpower, improve work efficiency, and operate simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

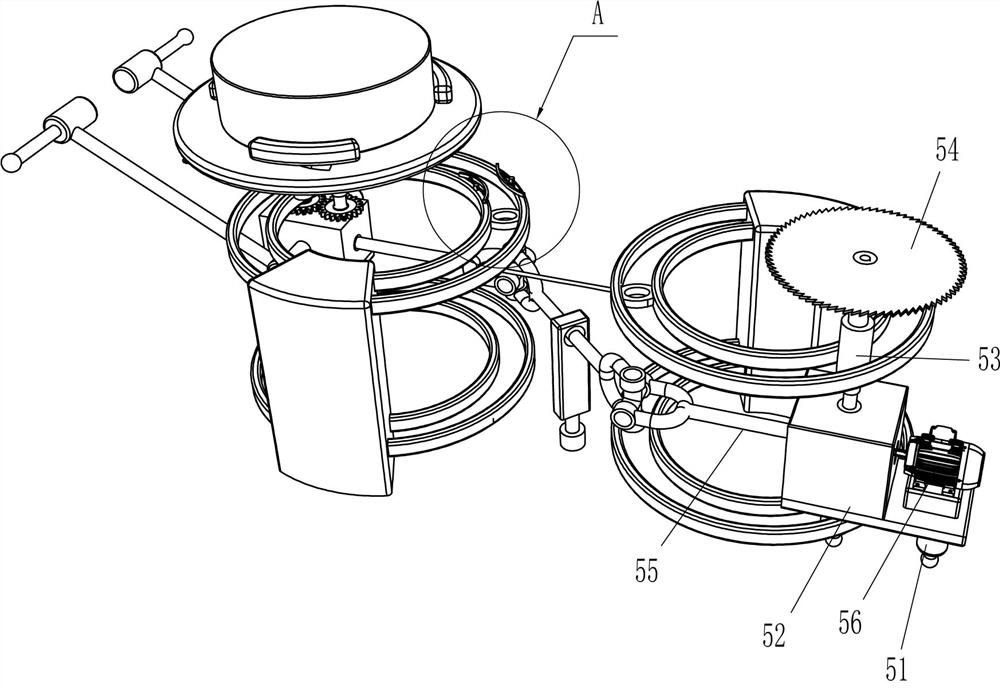

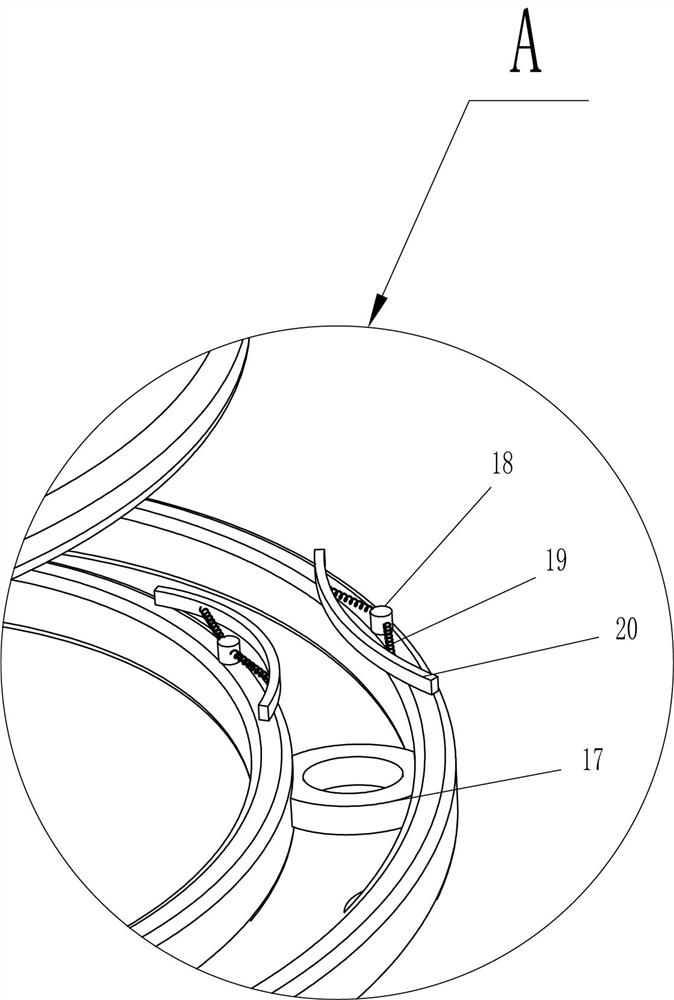

[0027] A cutting board grooving device, such as Figure 1-5 As shown, it includes a workbench 1, a mounting plate 2 and an annular slide rail 3, the left and right sides of the top of the workbench 1 are connected with the installation plate 2, the upper and lower sides of the installation plate 2 are connected with the annular slide rail 3, and there are also clips Tightening device 4, cutting device 5, second rotating shaft 6, bearing housing 7, first rotating rod 8, second rotating rod 9, multi-directional rotating shaft 10, push rod 11 and blanking box 12, the right mounting plate 2 A clamping device 4 is provided between the two circular slide rails 3, a cutting device 5 is provided between the two circular slide rails 3 on the left mounting plate 2, and a second rotating shaft 6 is rotatably connected in the middle of the top of the workbench 1. The second rotating shaft 6 is connected with a bearing seat 7, the upper part of the bearing seat 7 is rotatably connected wit...

Embodiment 2

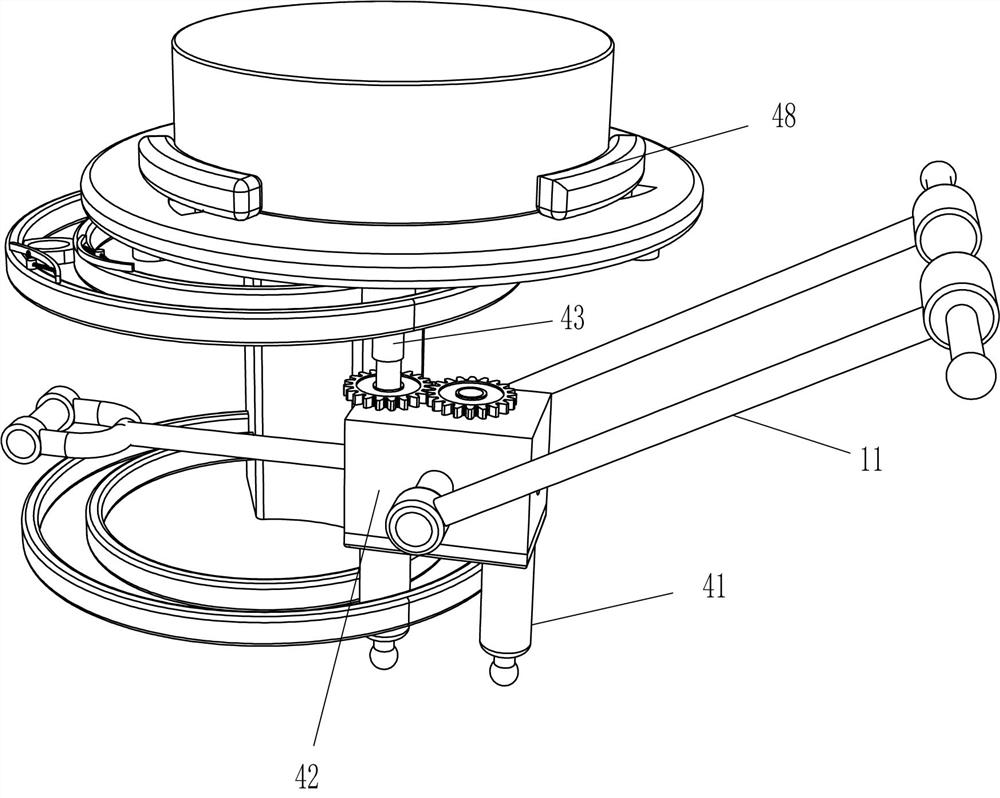

[0032] On the basis of Example 1, such as Figure 6-7 As shown, it also includes a third rotating shaft 13, a fourth rotating shaft 14, a second bevel gear 15 and a circular gear 16, and the first mounting box 42 is rotationally connected with the third rotating shaft 13, and the third rotating shaft 13 and the second rotating rod 9 connection, the upper part of the first installation box 42 is rotatably connected with the fourth rotating shaft 14, the fourth rotating shaft 14 and the third rotating shaft 13 are connected with the second bevel gear 15, the two second bevel gears 15 mesh with each other, the fourth A circular gear 16 is connected to the top of the rotating shaft 14 and the first rotating slide bar 43 , and the two circular gears 16 mesh with each other.

[0033] The first rotating shaft 55 also drives the first rotating rod 8 to rotate through the multidirectional rotating shaft 10 when rotating, and the first rotating rod 8 rotates to drive the second rotating...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com