Equipment for processing tag slot on side edge of chopping board

A label groove and chopping board technology, which is applied to wood processing equipment, slotting machines, manufacturing tools, etc., can solve the problems of low efficiency of manual work, and achieve the effects of reducing labor intensity, standard shape, and precise position

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

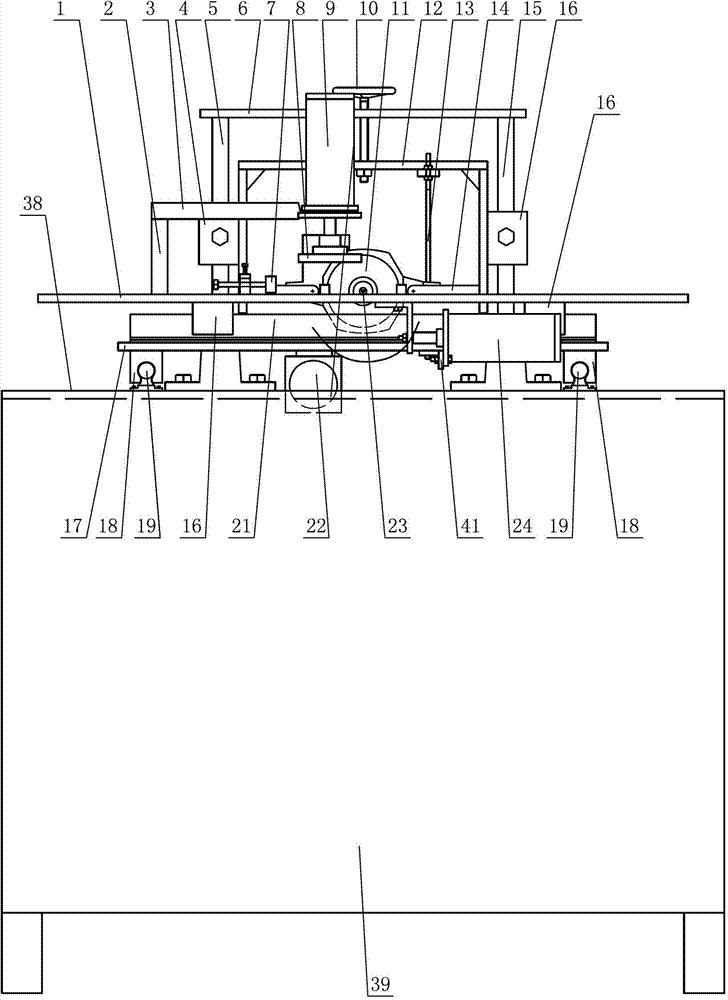

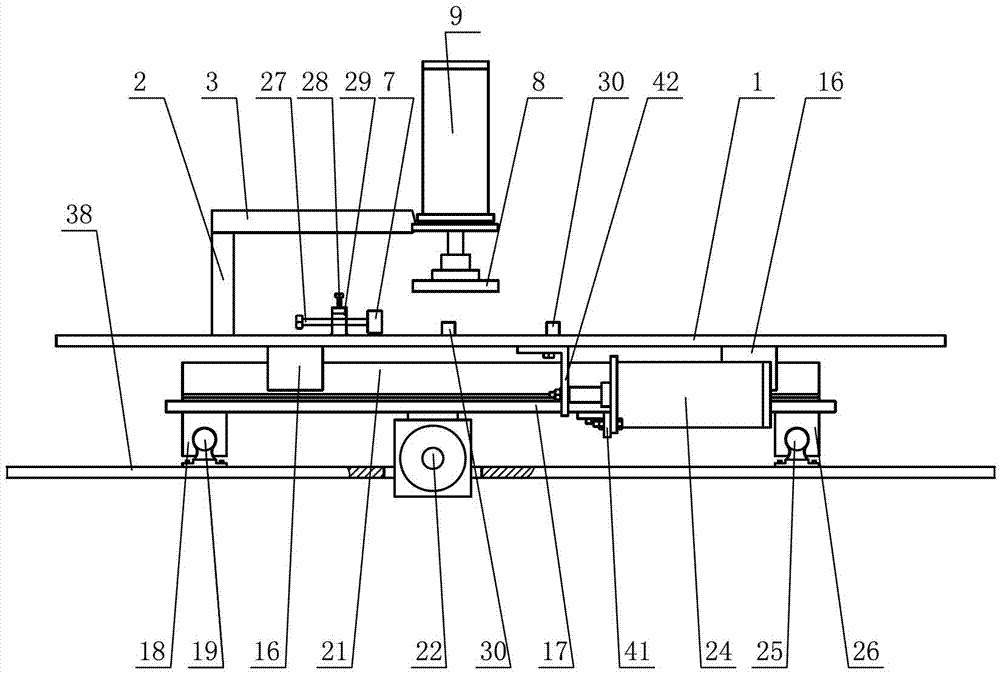

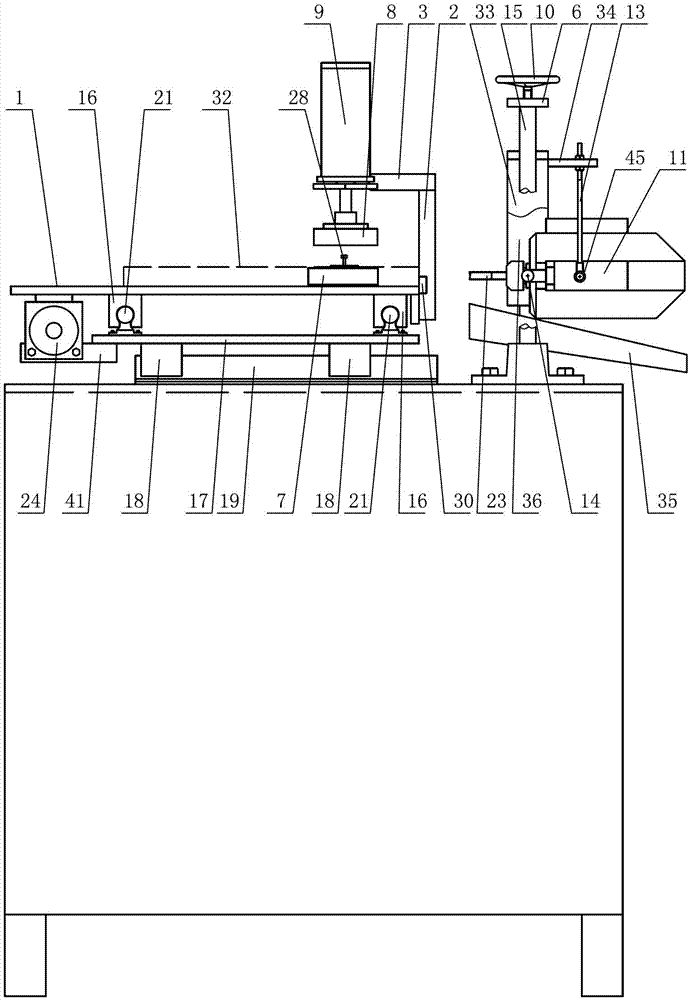

[0026] The device of the present invention will be further described below with reference to the accompanying drawings and in conjunction with a specific embodiment.

[0027] refer to figure 1 , 2 , in this example, the label groove processing equipment includes a frame, the main body part 39 of the frame is a box structure, a controller (not shown) is arranged inside, and a table panel 38 is above the frame. Two parallel linear guide rails 19 are vertically arranged on the table top 38, and four sliding sleeves 18 matched with the linear guide rails 19 on the table top 38 are symmetrically fixed below the clamping bottom plate 17, wherein every two sliding sleeves are fitted on On a linear guide rail, the bottom plate driving cylinder 22 is located below the clamping bottom plate 17, and is a double-action cylinder. The cylinder barrel is fixed to the table panel, and the piston rod protrudes forward. The facade is fixed.

[0028]Two parallel linear guide rails 21 are hori...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com