Cutting apparatus and method

A device, technique of guides, used in mortise recesses, devices for holes such as cylindrical cylinder pin lockholes or round handle shaft holes, devices for hinge notches or latch plate notches, and for cutting letterboxes on facades Equipment field of opening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

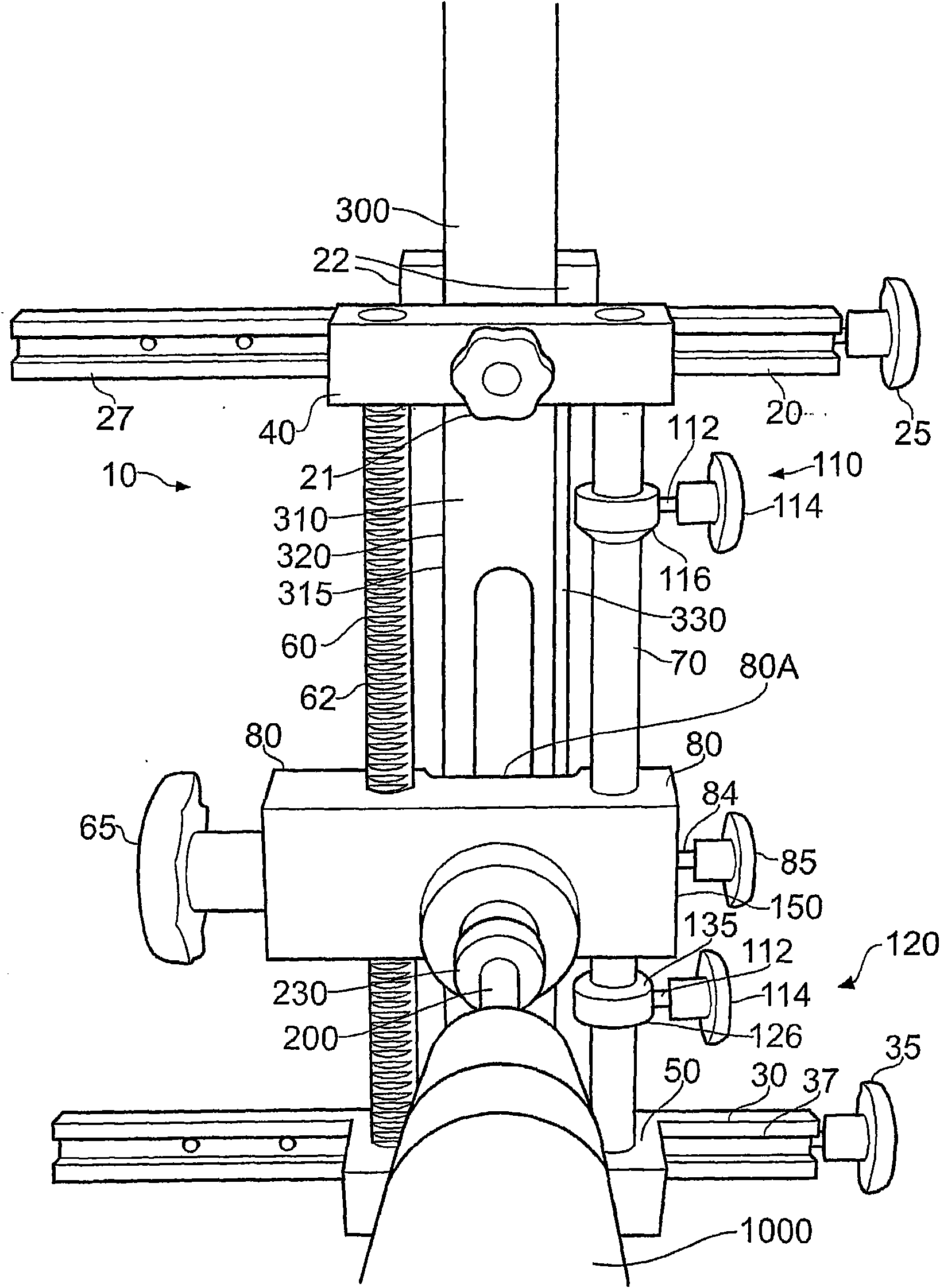

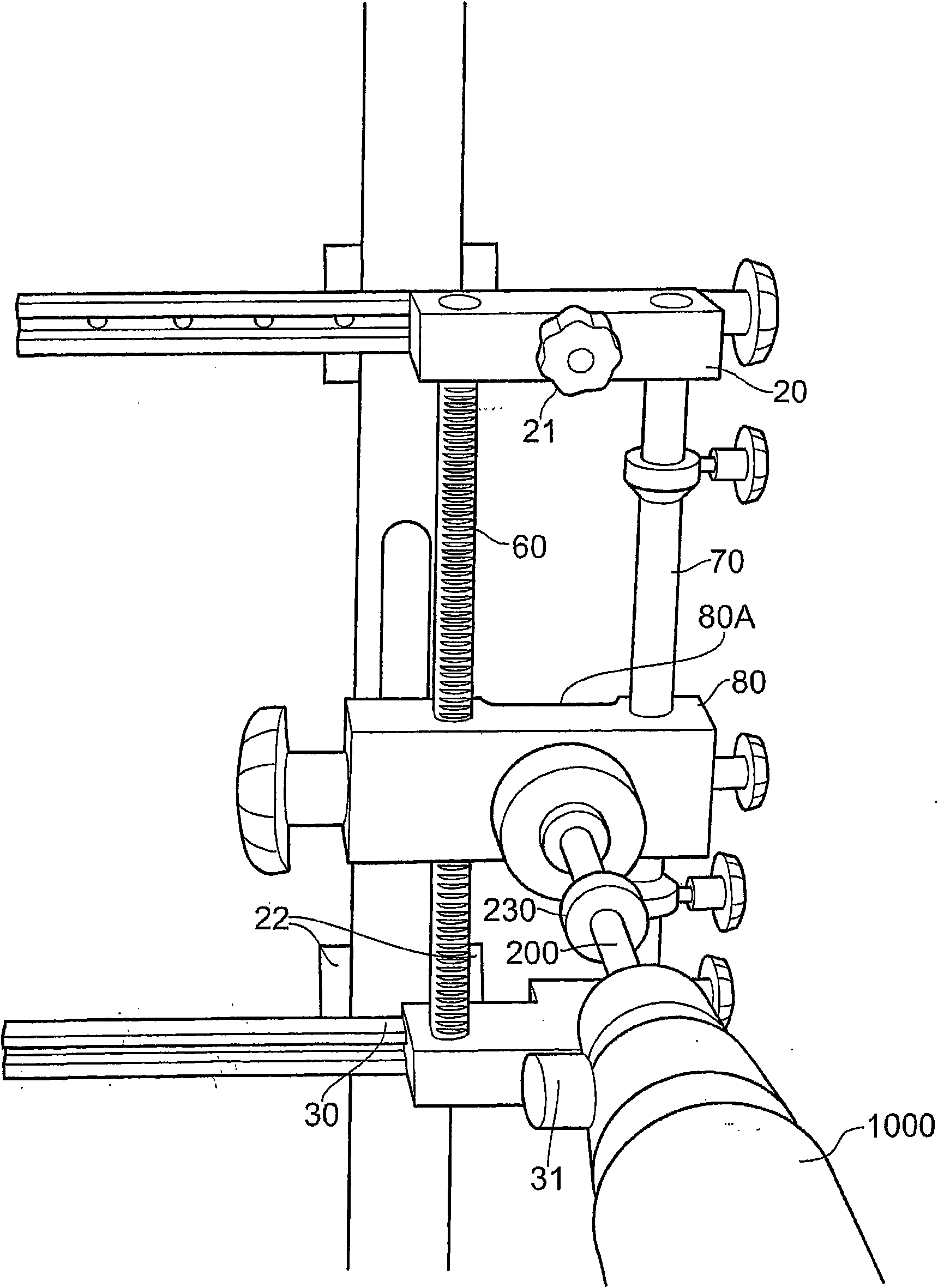

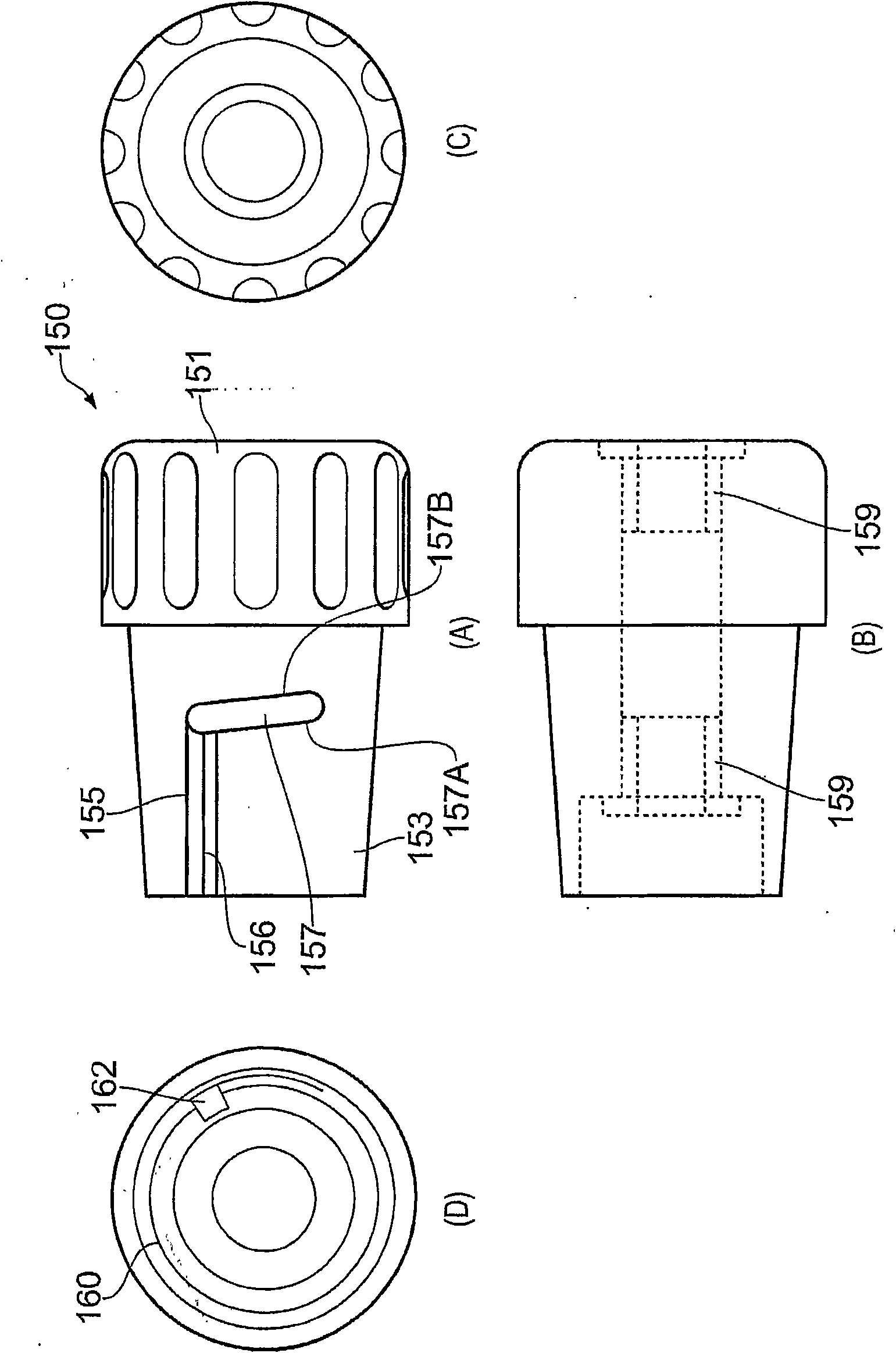

[0087] The carrier 80 has a bearing block 150 that fits within a bearing block hole 160 of the carrier 80 . The bearing block 150 has a through axial hole through which the drill bit 200 can pass. According to a first embodiment, the bore is lined with a pair of low-friction bushings 159 which grip the inner surface of the bearing block 150 tightly. In a variant of the first embodiment, the bushing is glued inside the hole. A drill bit inserted through the bore is slidably rotated relative to the bushing.

[0088] The bearing block 150 is oriented so that, in use, the axis of rotation of the drill head 200 is substantially normal to the slide bar 70 and transverse to the slide rails 20,30. The bearing block is located between the rack 60 and the slide bar 70 .

[0089] Liners are made of porous metal materials such as sintered (e.g., Oilite TM Bearings) made of self-lubricating materials. In some embodiments, the bushing is made of a low friction plastic material such as ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Cone angle | aaaaa | aaaaa |

| Cone angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com