Full-automatic profiling cutter for wooden floor substrate

A wood floor, fully automatic technology, used in slotting machines, sawing equipment, mortising machines, etc., to stabilize wood floor substrates, reduce labor intensity, and improve accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

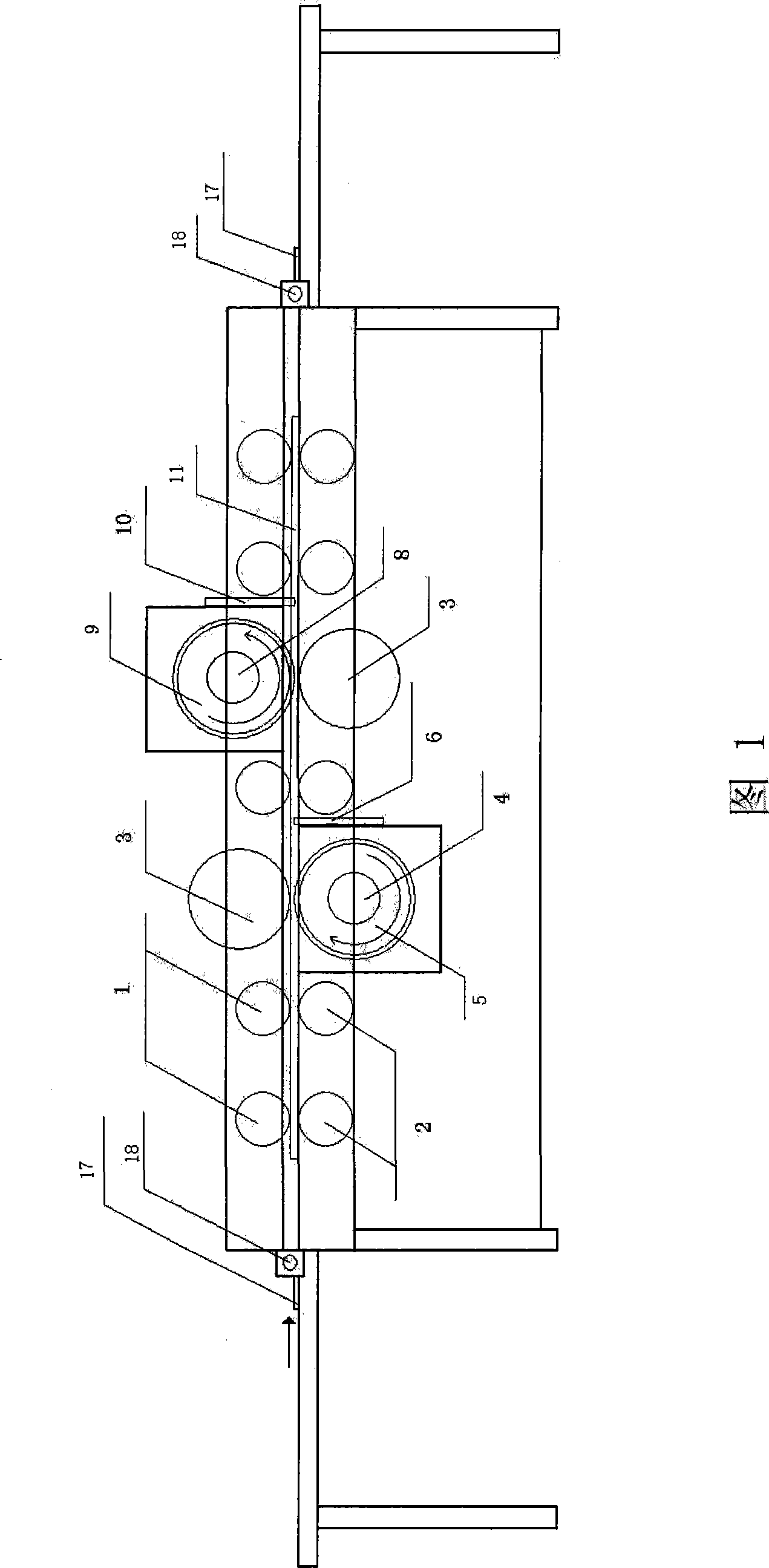

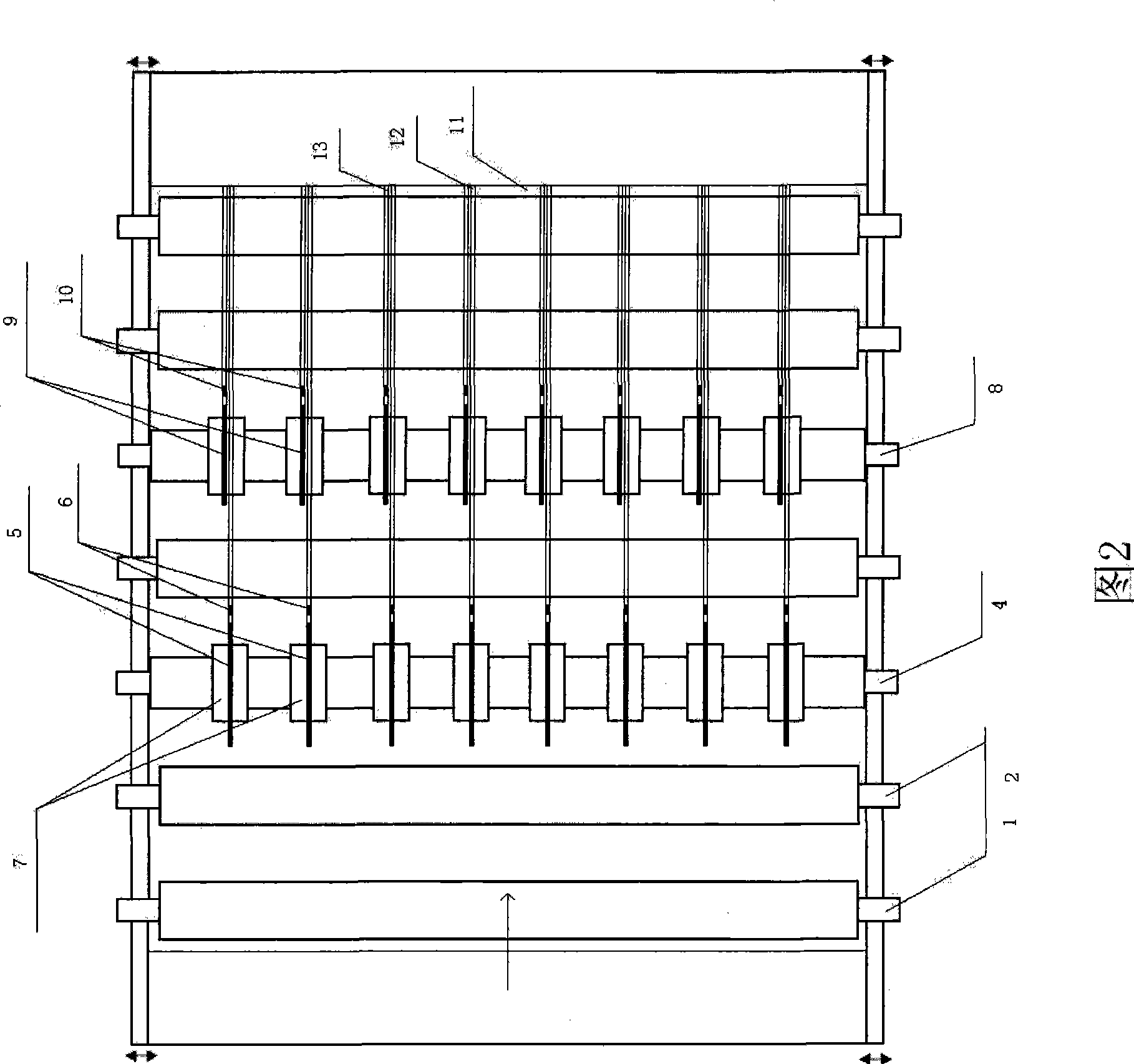

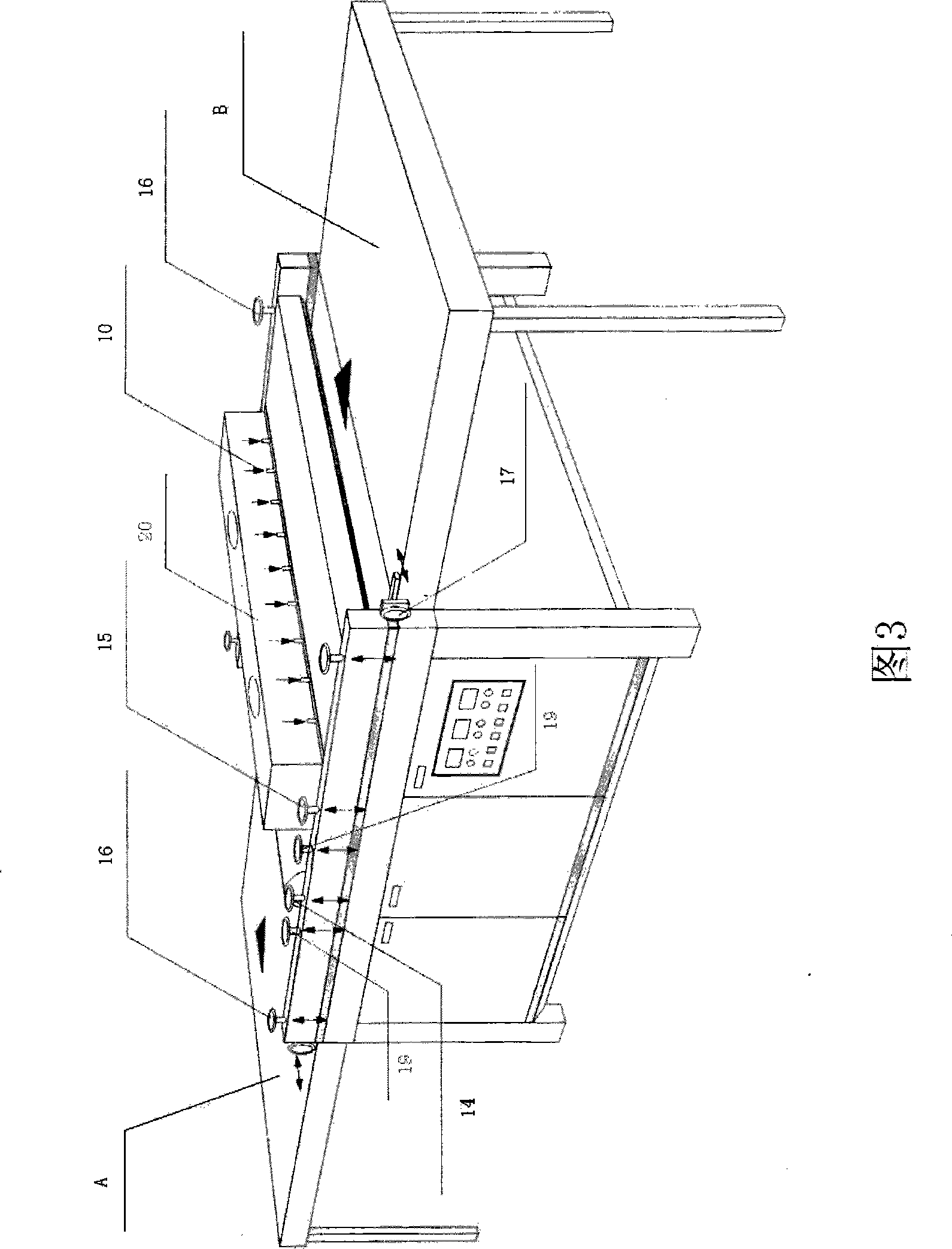

[0016] The embodiment of the device, as shown in Figure 1-3, includes cutting equipment, a lower groove sawing shaft 4 installed on the cutting equipment, a lower groove cutting knife 6, an upper groove sawing shaft 8, an upper groove cutting knife 10, an upper Guide conveying roller 1, lower guide conveying roller 2, positioning guide roller 3, and several lower groove cutting saw blades 5 installed on the lower groove sawing shaft 4 and several upper groove cutting blades installed on the upper groove sawing shaft 8 Saw blade 9 forms.

[0017] Specific implementation steps:

[0018] 1. According to the number of slices of the wooden floor substrate 11 and the cutting positions of the upper groove and the lower groove (parallel dislocation), use the saw blade positioning sleeve 7 to install and fix the upper groove cutting saw blade 9 on the upper groove sawing shaft 8, Use the saw blade positioning ferrule 7 to install and fix the lower groove cutting saw blade 5 on the low...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com