Portable wooden floor groove cutting machine

A wooden floor and slotting machine technology, which is applied in slotting machines, mortising machines, forming/shaping machines, etc., can solve the problems of being unsuitable for on-site use of wooden floor laying, and achieves light weight, simple structure, and portability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

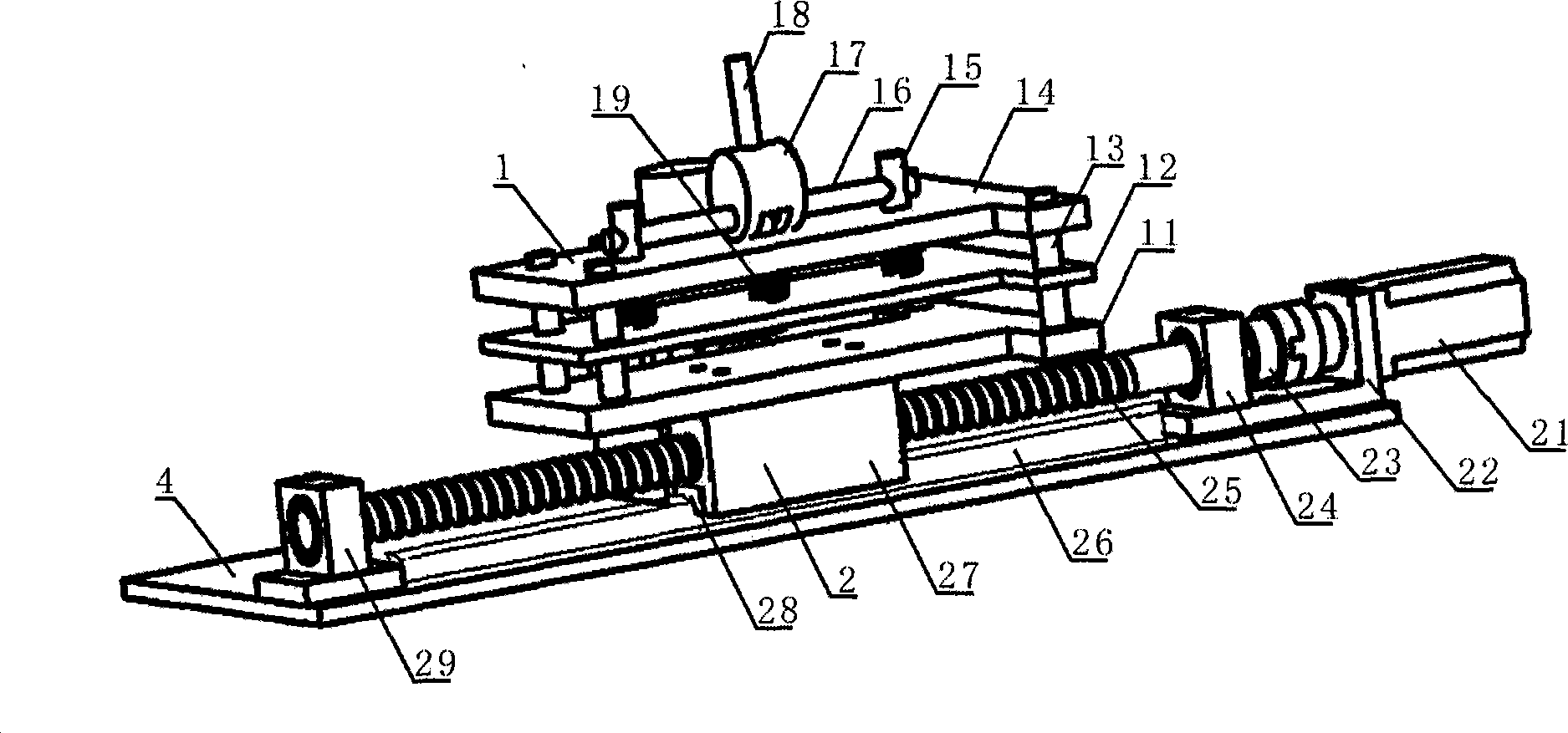

[0018] figure 1 Description of marks: clamping and positioning device 1, lower splint 11, upper splint 12, guide rod 13, support plate 14, pull rod 15, pull rod shaft 16, eccentric wheel 17, eccentric wheel handle 18, spring 19, feed device 2, Feed motor 21, feed motor support 22, coupling 23, screw mandrel front support 24, screw mandrel 25, linear guide 26, screw mandrel nut 27, slide block 28, screw mandrel rear support 29, frame 4.

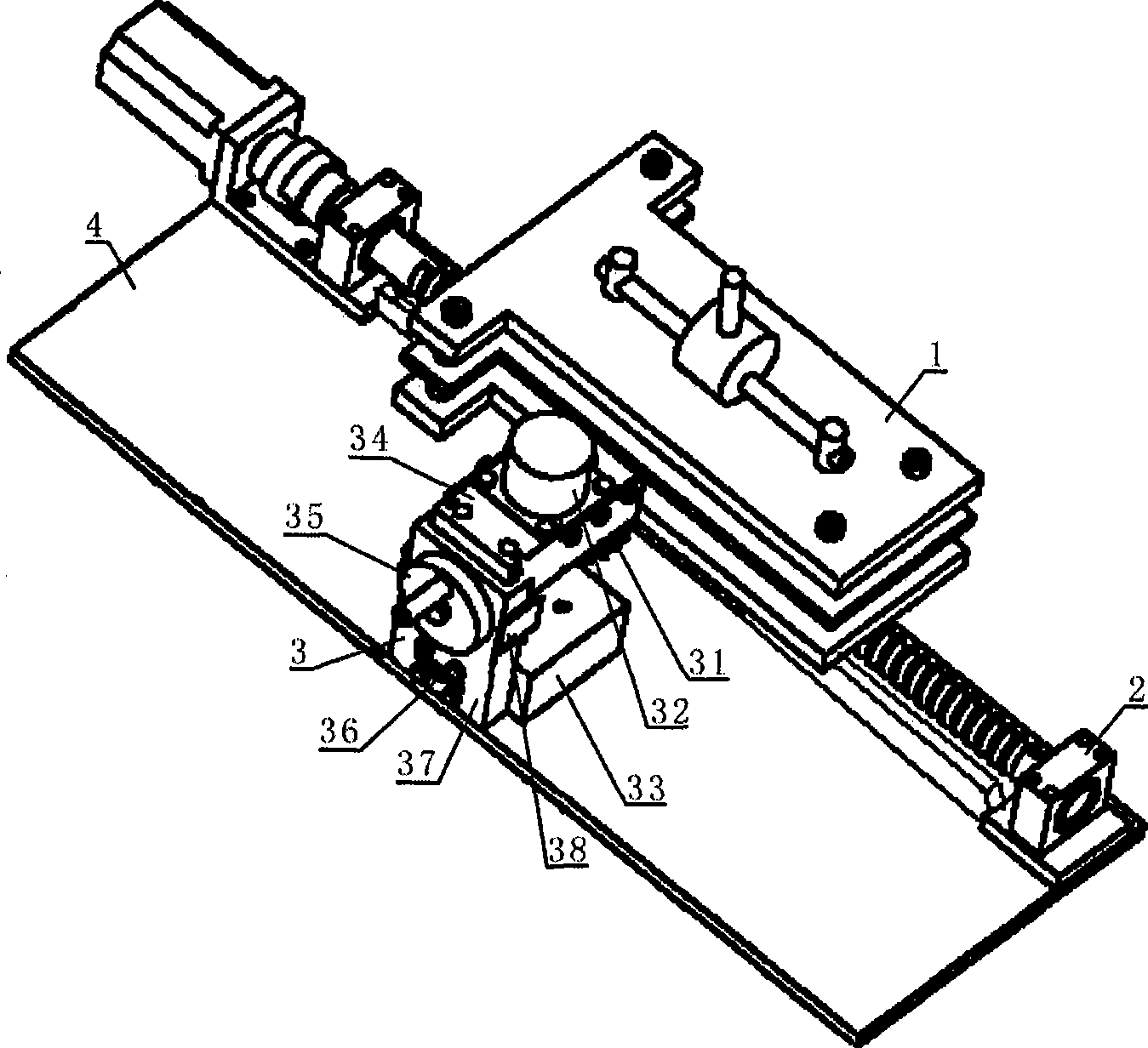

[0019] figure 2 Explanation of marks: milling cutter device 3 , milling cutter 31 , milling cutter motor 32 , base 33 , knife rest 34 , adjustment wheel 35 , adjustment knob 36 , bracket 37 , clamping piece 38 .

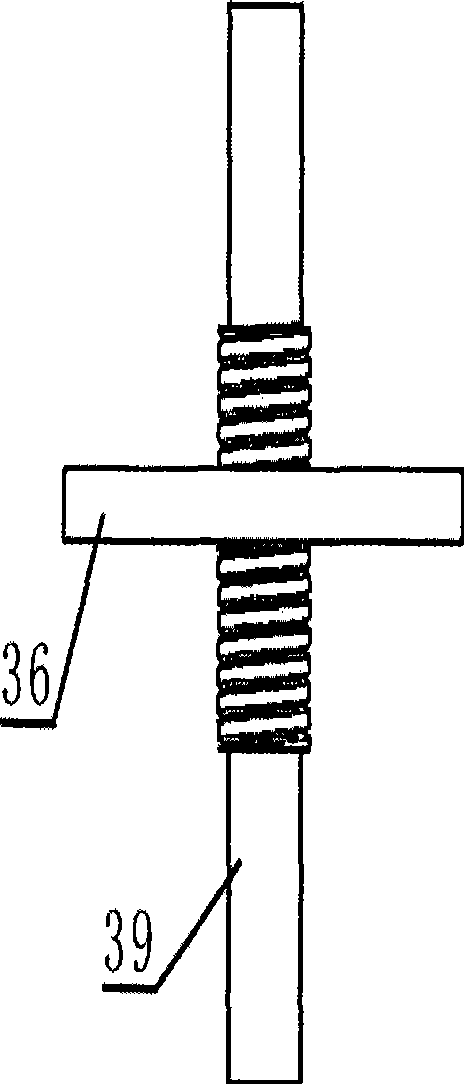

[0020] image 3 Description of markings: Ejector 39.

[0021] see figure 2 , the portable wooden floor slotting machine of the present invention comprises milling cutter device 3, feeding device 2, clamping positioning device 1 and frame 4; Milling cutter device 3 and feeding device 2 are installed on the frame 4, clamping and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com