Colour combination V-groove composite floor block and mfg. method thereof

A compound flooring and manufacturing method technology, applied in the direction of manufacturing tools, slotting machines, tenon making devices, etc., can solve the problems of single color, dull visual effect, etc., and achieve good visual effect, rich color, and simple and easy manufacturing process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

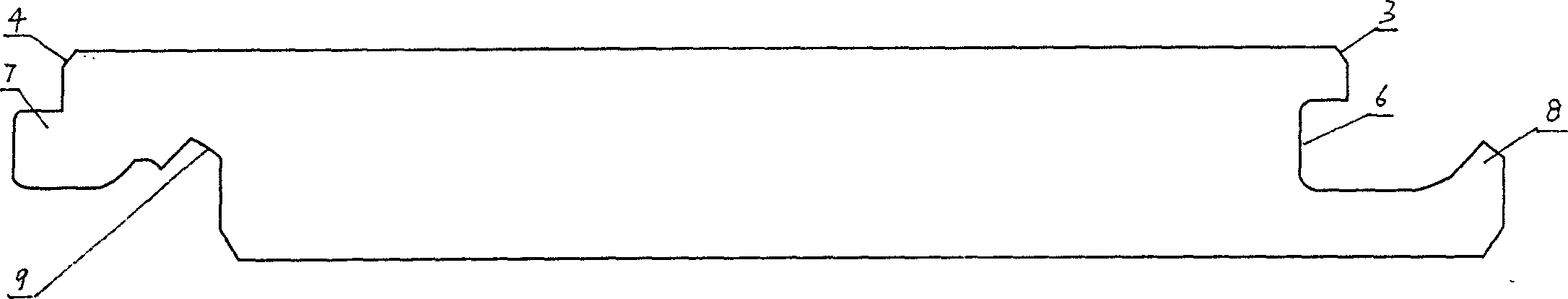

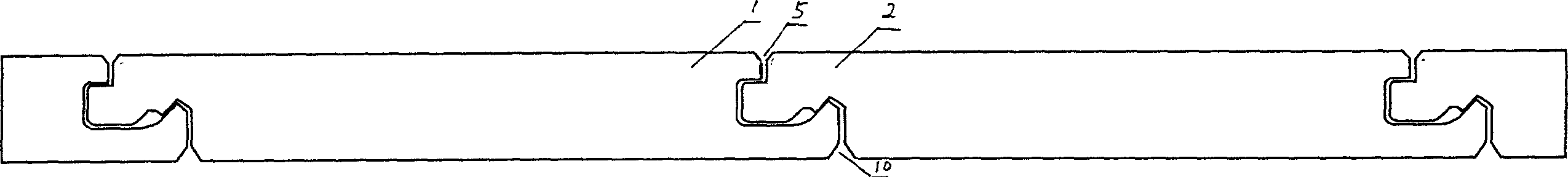

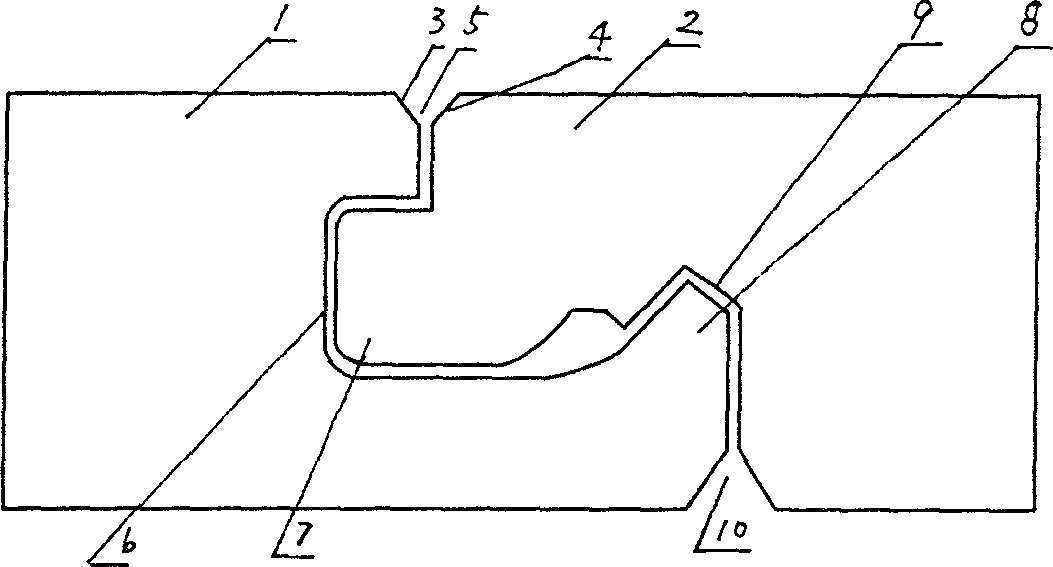

[0023] figure 1 One embodiment of a color-matched V-groove laminate flooring of the present invention is shown. The laminate floor is made of figure 2 The shown several strips of rectangular composite floors are laid, and on both sides of the top surface of each rectangular composite floor, an oblique angle is respectively turned outward along its length direction, that is, image 3 The shown chamfer I3 and chamfer II4 make a V-shaped chamfer groove 5 be formed on both sides of the top surface of the adjacent rectangular composite floor I1 and composite floor II2 after splicing. The surface of each V-shaped chamfering groove 5 is provided with a color-matching layer of a different color from that of the composite floor body. are firmly connected. The color matching of the V-shaped groove and the composite floor body can be similar or completely dif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com