High speed timber tenon-making machine

A tenoning machine and wood technology, used in tenoning devices, wood processing appliances, making tongues or tongues and grooves, etc., can solve the problems of slow production speed, low efficiency and high price, and achieve simple structure, convenient use, Inexpensive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

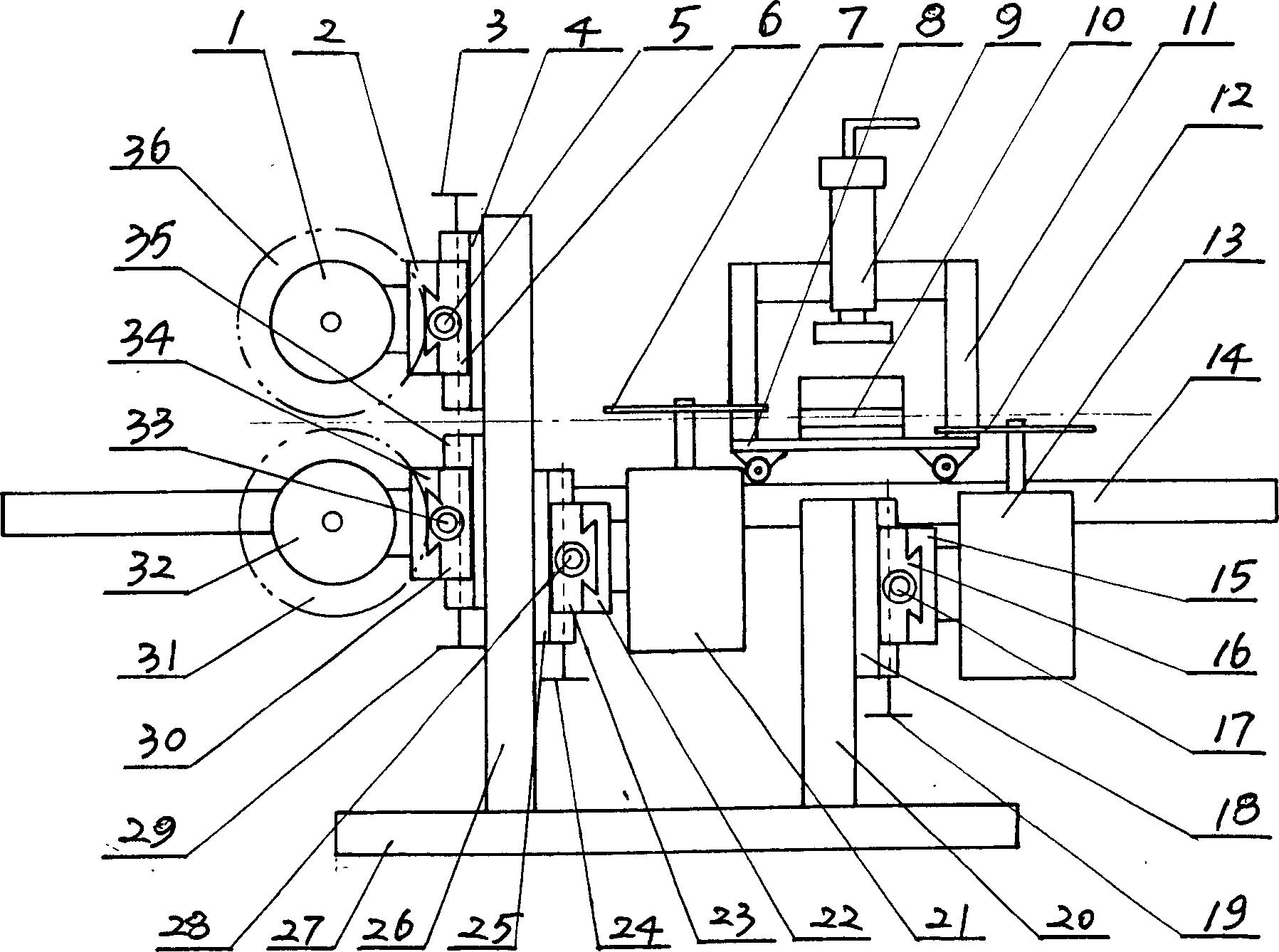

[0009] In the figure, the fixed seat, the lifting seat and the transverse seat are all precisely slid and fitted through the dovetail and the dovetail groove. The precision of the fit is not good, which directly affects the precision of the tenon.

[0010] In the figure, the two tracks themselves require a high degree of parallelism, a small level difference, and a smooth and flat surface; in addition, the entire track and the vertical frame are required to be perpendicular to each other, and the vertical accuracy directly affects the precision of the tenoning.

[0011] In the figure, two vertical frames will be parallel to each other, and keep vertical with horizontal support (27), and its surface also will be clean and level.

[0012] In the figure, the circular saw blades (36), (31) installed on the output shaft of the motor are in a vertical state with the horizontal support (27). ) is in the same horizontal state as the working platform, and what it cuts are the upper and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com